A kind of waste pet heat-resistant viscosifying reinforced composite material and its preparation process

A technology for reinforcing composite material and preparation process, which is applied in the field of waste PET heat-resistant and tackifying reinforced composite material and its preparation process, can solve the problems of poor product quality, inability to mix waste PET and additives evenly, etc., and achieves viscosity enhancement and delay. Oxidation or auto-oxidation process, the effect of increasing toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation technology of waste and old PET heat-resistant thickening reinforced composite material, it comprises the following steps:

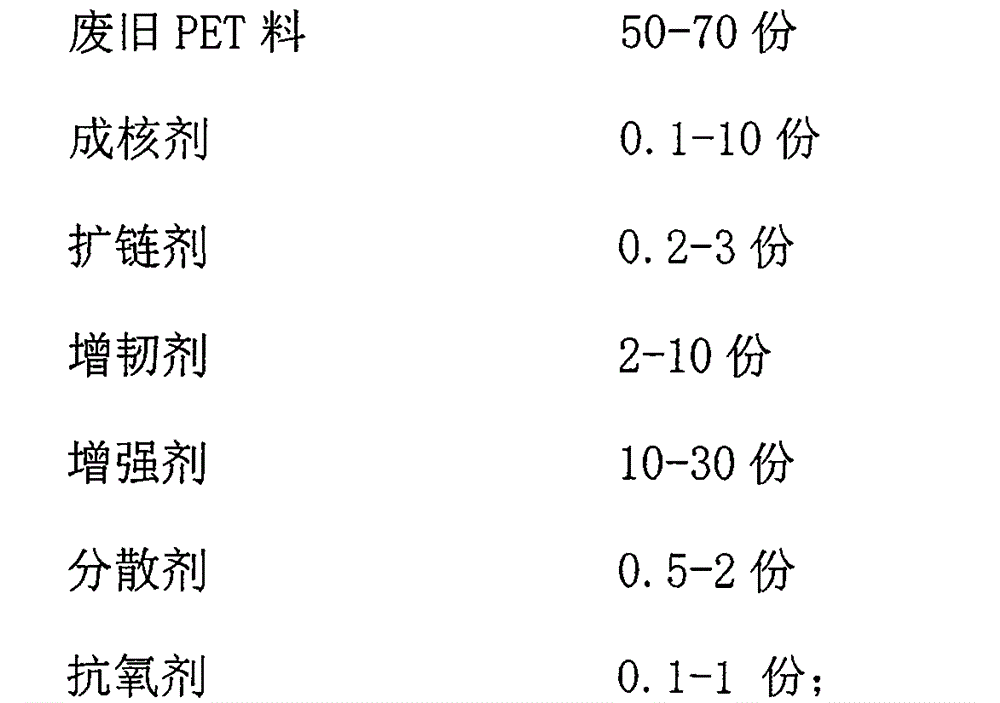

[0026] Step 1. Prepare the following ingredients:

[0027]

[0028] Step 2, drying the crushed and cleaned waste PET main material at 120°C for 5 hours;

[0029] Step 3, putting the waste PET and the toughening agent dried in step 2 into a mixer and stirring at high speed to obtain the first blend;

[0030] Step 4, putting the dispersant, chain extender, nucleating agent and antioxidant into a high-speed mixer and blending for 3-6 minutes to obtain the second blend;

[0031] Step 5. Add the first blend to the main feed port, add the second blend to the powder side feed port attached to the main feed port, and then move the enhancer to the side feed on the side of the twin-screw extruder In the feed port, set the temperature of each zone of the extruder at 220-280°C for extrusion molding.

[0032] In step 5 of the above ...

Embodiment 2

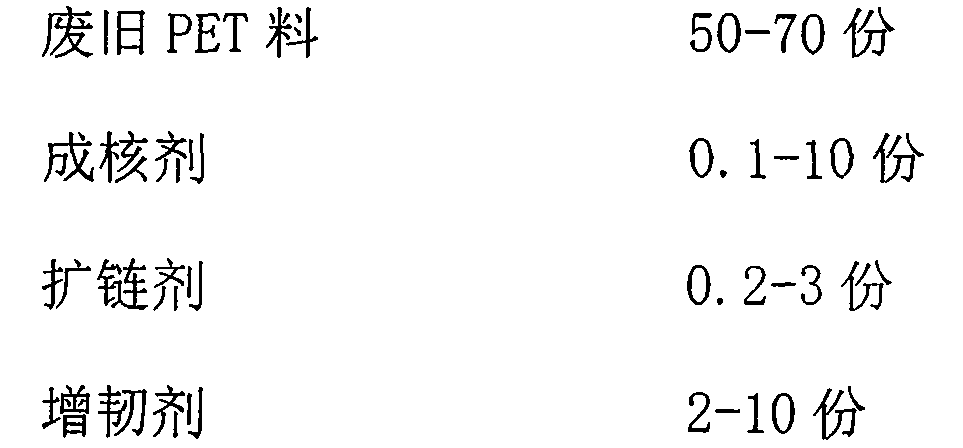

[0038] A kind of waste and old PET heat-resistant viscosity-increasing reinforced composite material that adopts the preparation technology of embodiment 1 to make, its component and parts by weight ratio are as follows:

[0039]

Embodiment 3

[0041] A kind of waste and old PET heat-resistant viscosity-increasing reinforced composite material that adopts the preparation technology of embodiment 1 to make, its component and parts by weight ratio are as follows:

[0042]

[0043] The following list is the test data of this embodiment compared with the performance of the waste PET modified material prepared by the prior art, and the test data can intuitively reflect the performance of the waste PET heat-resistant viscosity-increasing reinforced composite material of the present invention:

[0044]

[0045] As can be seen from the above table, the waste and old PET heat-resistant viscosifying reinforced composite material prepared by the waste PET heat-resistant viscosifying reinforced composite material preparation process of the present invention has low melt flow index, high viscosity, high tensile strength and impact resistance. Strong capacity, high bending strength, high HDT (heat distortion temperature), all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com