Spunlaid, pulp airlaid and spunlace-bonded non-woven fabric production process

A pulp air-laid and spun-laid technology, which is applied in the field of non-woven fabrics and non-woven fabric production technology, can solve the problems of unsatisfactory non-woven fabrics, hard hand feeling of non-woven fabrics, and poor strength of non-woven fabrics. , to achieve the effect of overcoming poor softness, difficult dyeing, and poor water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

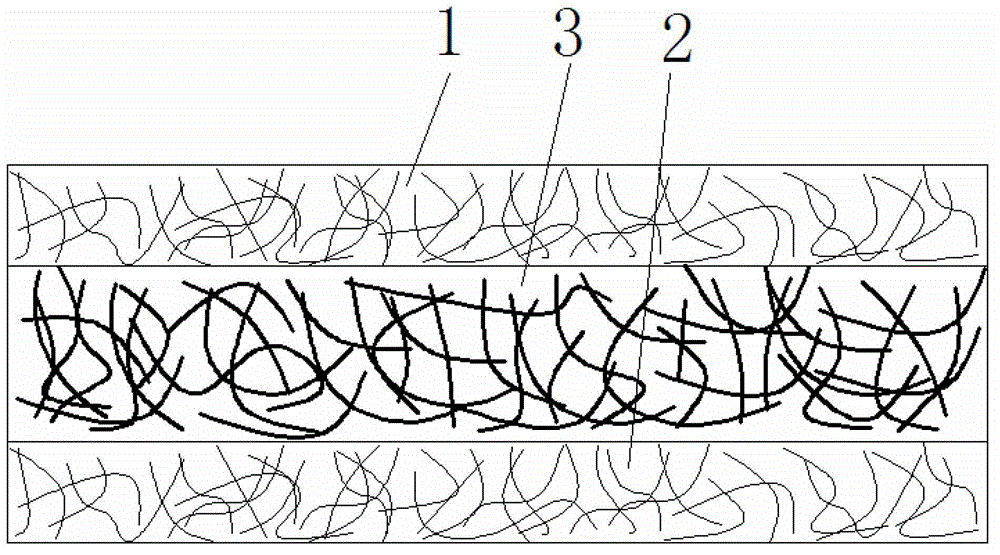

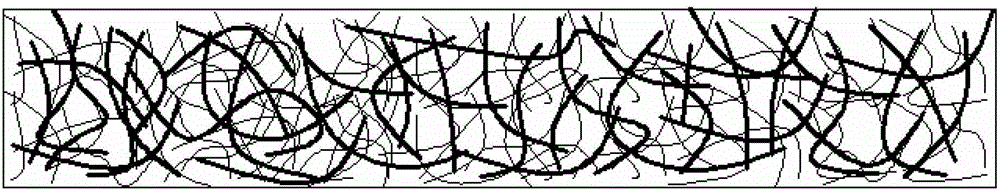

[0031] refer to figure 1 , 2 , the spun-laid pulp air-laid hydroentangled consolidated nonwoven fabric of the present invention includes a first fiber web 1, a second fiber web 2 and a pulp fiber layer 3, and the pulp fiber layer 3 is located in the first Between a fiber web 1 and the second fiber web 2, the thickness of the first fiber web 1 is 0.3-0.4 mm, the thickness of the second fiber web 2 is 0.1-0.5 mm, and the thickness of the pulp fiber layer 3 is 0.5~0.8mm.

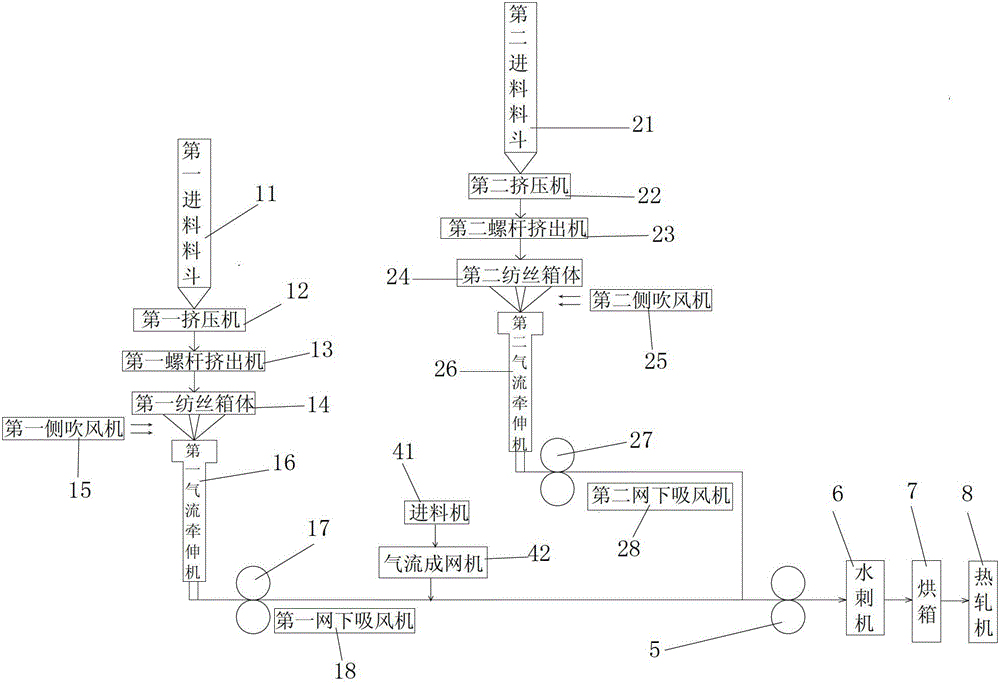

[0032] refer to image 3 , the production process of spunlaid pulp air-laid spunlace consolidated nonwoven fabric of the present invention, comprises the following steps successively:

[0033] a) Feed: Pour the polypropylene fiber into the first feed hopper 11 and the second feed hopper 21, and install the pulp pulp in the feeder 41;

[0034] b) Melting: firstly, the polypropylene fiber in the first feeding hopper 11 is sent into the first extruder 12 for extrusion processing, and the polypropylene fiber in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com