Non-chain-pillar roadway protection method adopting filling beside thin coal seam roadway

A technology with no coal pillars and thin coal seams, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of high cost, poor effect of roadway retention, and high labor intensity, so as to achieve convenient operation, ensure the stability of surrounding rock, The effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

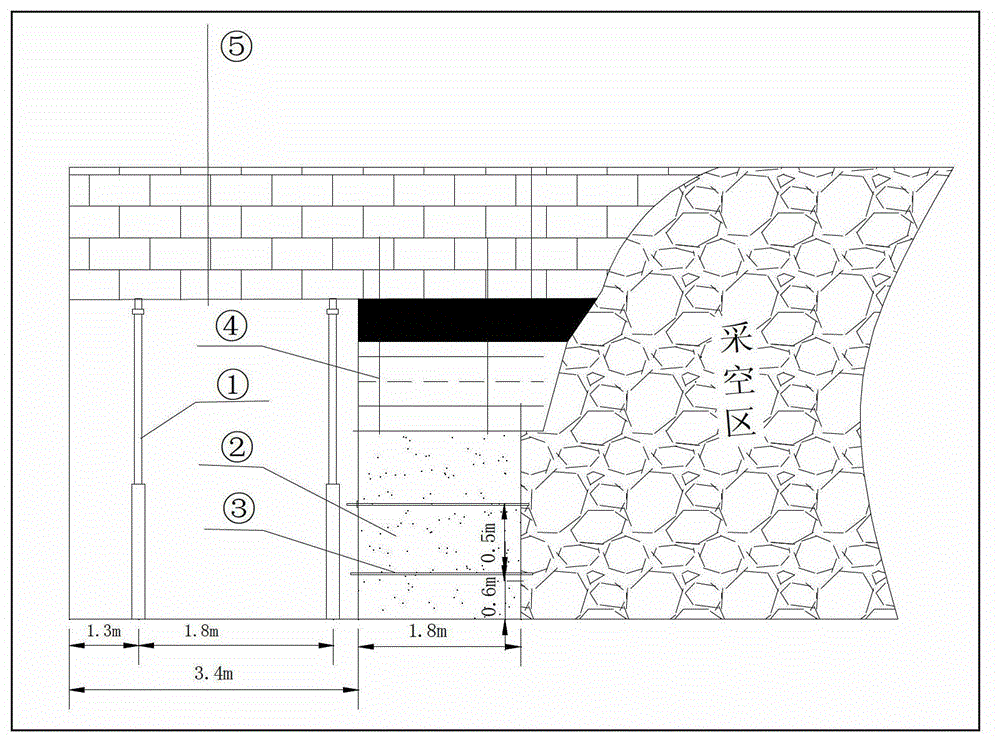

[0022] Combined with the accompanying drawings, a roadway protection method for filling non-coal pillars next to a thin coal seam roadway, the roadway support is based on the original anchor net support, supplemented with anchor cables and additional single hydraulic props to strengthen the support, the roadway The side support is bag-filled with high-water materials. Specifically include the following steps:

[0023] (1) Reinforcement and support of the roadway roof: Anchor cables are added in the reserved roadway and within 20m of the advanced working face. The anchor cables are arranged along the axis of the roadway, one every 3m, and the length of the anchor cables is set to 5m.

[0024] (2) Roadway advance support: Add single hydraulic props in the reserved roadway and within 20m of the advance working face; single hydraulic props are also arranged along the axis of the roadway, and a group of 2 pieces is arranged every 1.5m.

[0025] (3) Rock strata control above the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com