Secondary air distribution method for pulverized coal boiler with swirling combustion of front-back hedging

A pulverized coal boiler and swirl burner technology, applied in the direction of combustion method, combustion control, air supply adjustment, etc., can solve the problems of low accuracy, burning out of the burner outlet, environmental damage, etc., to overcome the inaccuracy High, improve combustion efficiency, reduce pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and the achieved effects, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and preferred embodiments.

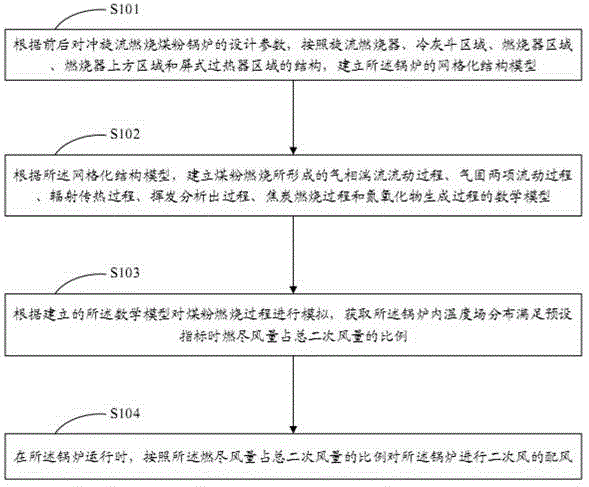

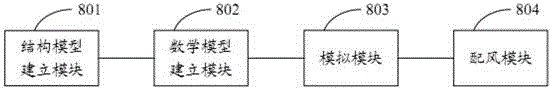

[0027] see figure 1 , is a flow diagram of the method for distributing secondary air of the pulverized-coal fired boiler with front and rear opposing swirl combustion in the present invention. The method for distributing the secondary air of the pulverized-coal fired boiler with front and rear opposing swirling flow of the present invention comprises the following steps:

[0028] S101 According to the design parameters of the front and back swirling combustion pulverized coal boilers, and according to the structure of the swirling burner, cold ash hopper area, burner area, area above the burner, and panel superheater area, establish the grid of the boiler structural model;

[0029] S102 Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com