Wind energy heating unit and operation method thereof

An operation method and wind energy technology, which are applied in wind turbine combinations, refrigerators, wind energy power generation, etc., can solve the problems of low application efficiency and inability to directly use heat, and achieve the effect of improving efficiency, improving actual use efficiency, and reducing combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

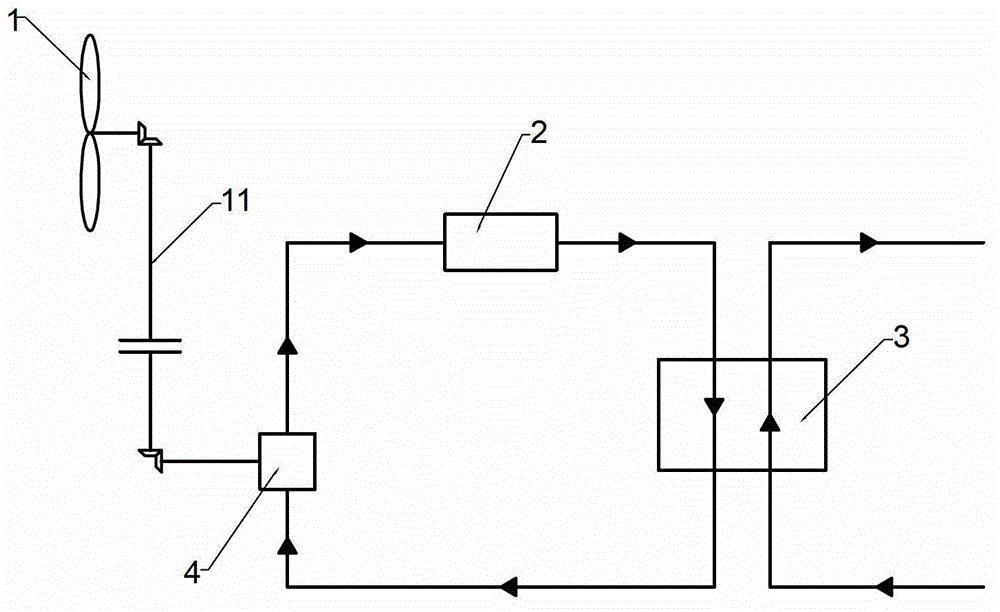

[0021] Embodiment 1, with reference to Figure 1-Figure 9 , a wind energy heating unit, comprising a windward blade 1, an oil pressure pump 4, a heat generating device 2 and an energy storage heat exchanger 3, the windward blade 1 is connected to drive the oil pressure pump 4 through a transmission shaft 11, and the oil pressure pump 4 The base is fixed on the ground, and the outlet end of the hydraulic pump 4 is connected with the heat generating device 2 by a pipeline. The energy storage heat exchanger 3 is provided with a heating fluid pipeline 32 and a heat-taking medium pipeline 33. The inlet 321 of the heating fluid pipeline is connected to the downstream of the heat generating device 2 by a pipeline, and the outlet 322 of the heating fluid pipeline is connected to the suction end of the hydraulic pump 4 by a pipeline.

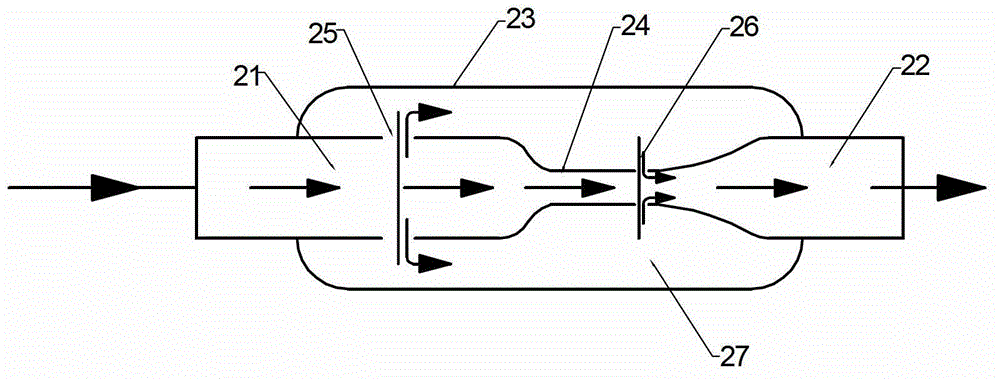

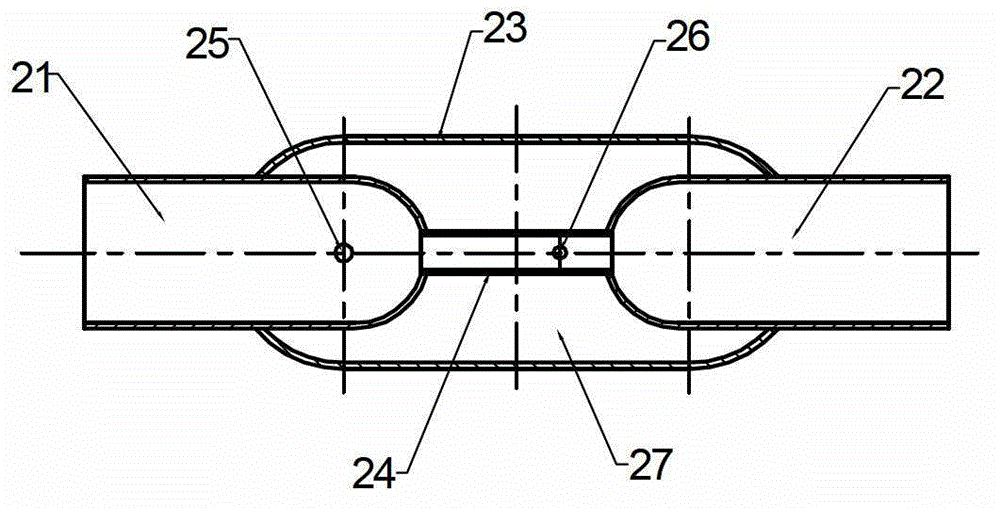

[0022] Among them, the heat generating device 2 is a special damping tube, which can be made of copper, duralumin or stainless steel, and is covered wit...

Embodiment 2

[0031] Embodiment 2, with reference to Figure 1-Figure 3 , the operation method of the wind energy heating unit described in Embodiment 1 is: the heating fluid is first driven by the oil pressure pump 4 to complete the energy conversion process of "wind energy → mechanical energy → pressure energy → kinetic energy → thermal energy" through the heat generating device 2; The high-temperature heating fluid flowing out of the heat generating device 2 enters the energy storage heat exchanger 3, and part of the heat energy of the heating fluid is transferred to the phase change material; the low-temperature heating fluid flowing out of the energy storage heat exchanger 3 is absorbed Return to the suction end of the oil pressure pump 4, and the heating fluid has completed a cycle; the wind energy drives the windward blade 1 to rotate, and drives the oil pressure pump 4 to work through the transmission device, so that the heating fluid circulates continuously in the system; the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com