Steam calcining furnace under pressure

A calciner and steam technology, applied in the direction of drying solid materials, non-progressive dryers, dryers, etc., can solve the problem of inability to ensure removal of crystal water and free water, unfavorable separation and discharge of finished materials, and failure to meet the needs of large-scale production and other problems to achieve uniform heating, reduce material loss, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

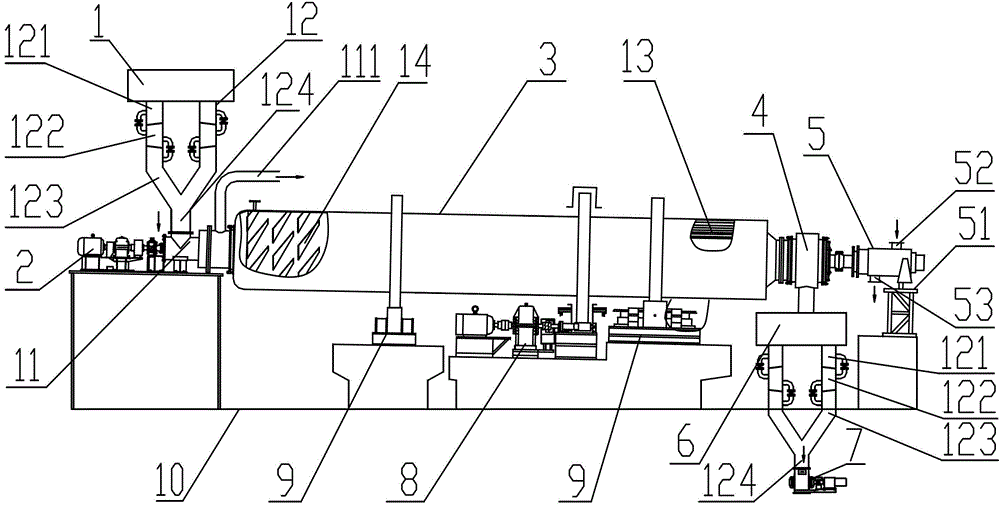

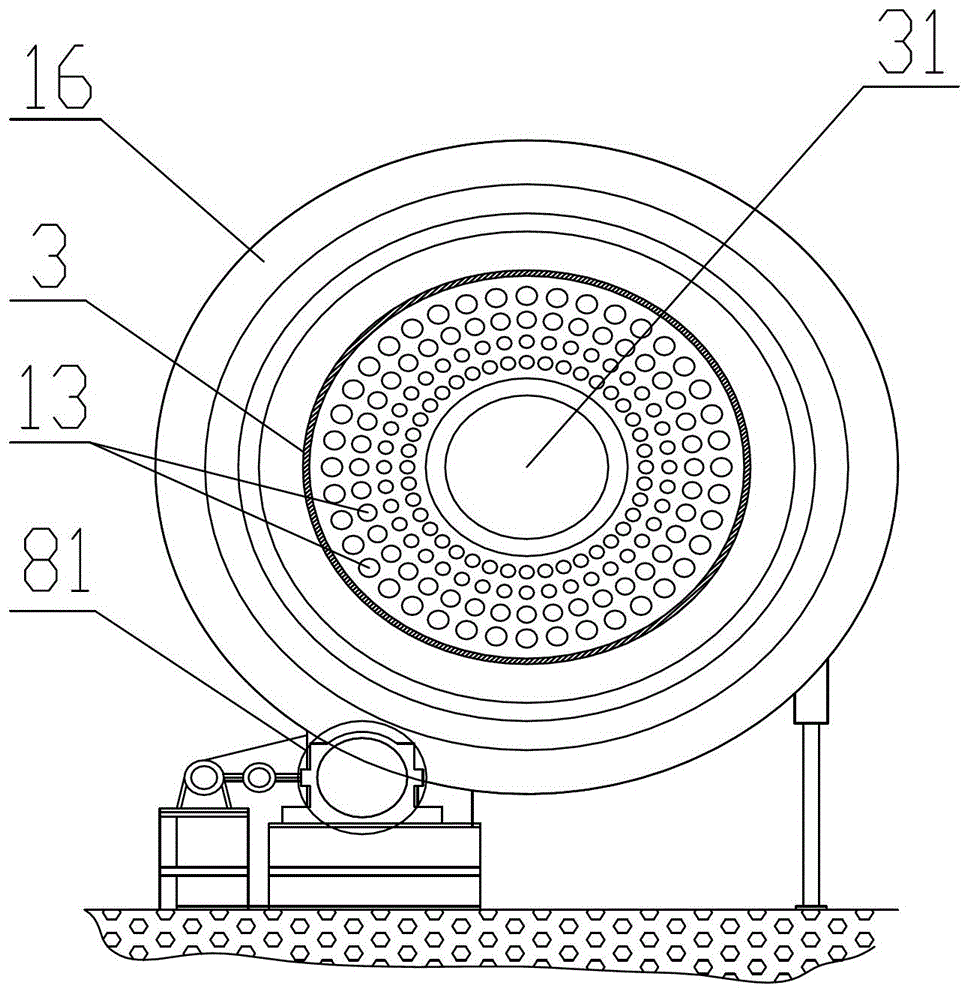

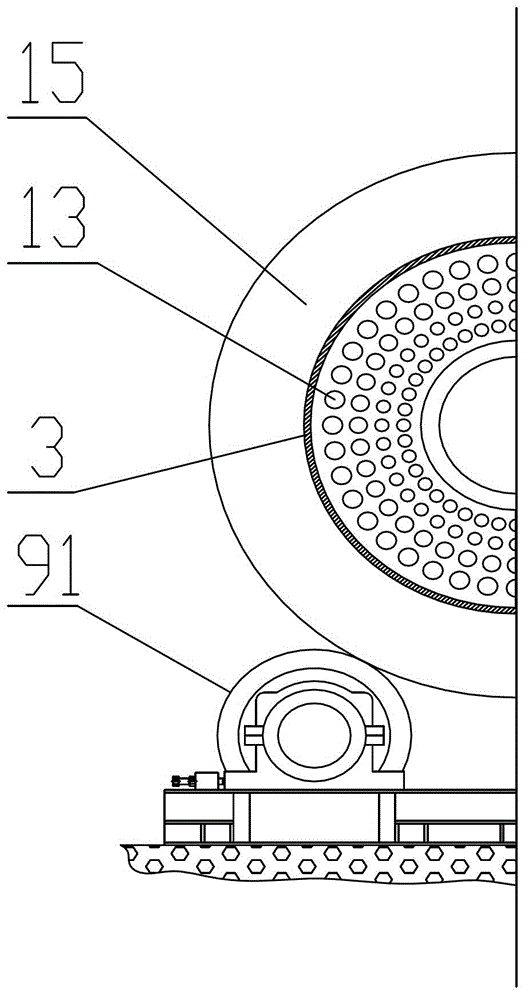

[0031] Such as Figure 1 ~ Figure 6 As shown, a pressurized steam calciner is mainly composed of a raw material bin 1, a feed bin 11, a furnace body 3 and a steam inlet shaft 5. The furnace body 3 has a reaction chamber 31, a feed bin 11 and a furnace body 3. The front end is connected, and a transmission device 8 is provided outside the furnace body 3, and the raw material warehouse 1 and the feeding warehouse 11 are connected through a three-stage feeding device 12. The front end of the furnace body 3 is an air outlet chamber, and a furnace gas outlet 111 is provided on the air outlet chamber. The steam inlet shaft 5 communicates with the rear end of the furnace body 3. The steam inlet shaft 5 has an inlet steam passage communicating with the reaction chamber 31 of the furnace body 3, and a steam inlet 52 is provided on the steam inlet shaft 5. An intermediate warehouse 4 is also provided between 5 and the furnace body 3, and a finished product warehouse 6 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com