Tension-compression-torsion-shearing coupling-based stress path triaxial apparatus

A stress path and triaxial instrument technology, which is applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of simple test stress paths, inability to perform tensile-torsional (shear) strength testing functions, and single instrument functions, etc. The effect of experimental error, convenient and reliable data collection, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

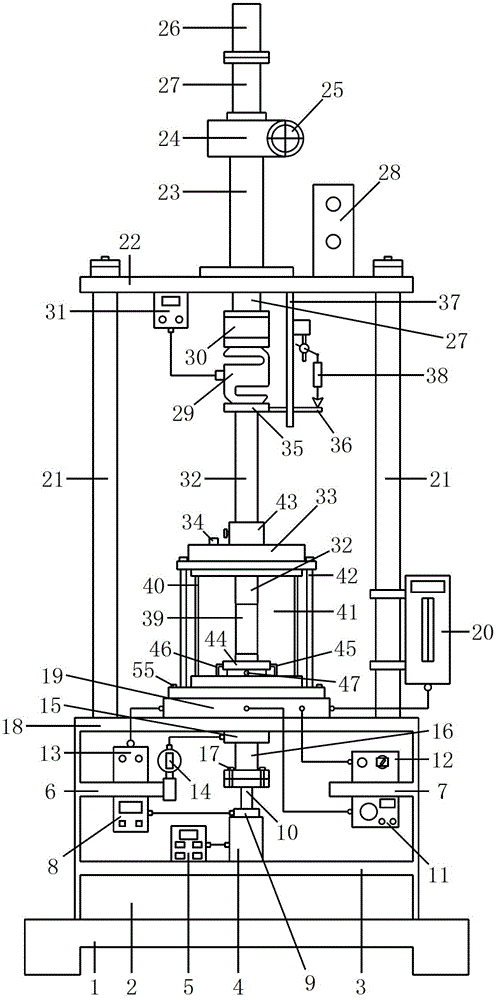

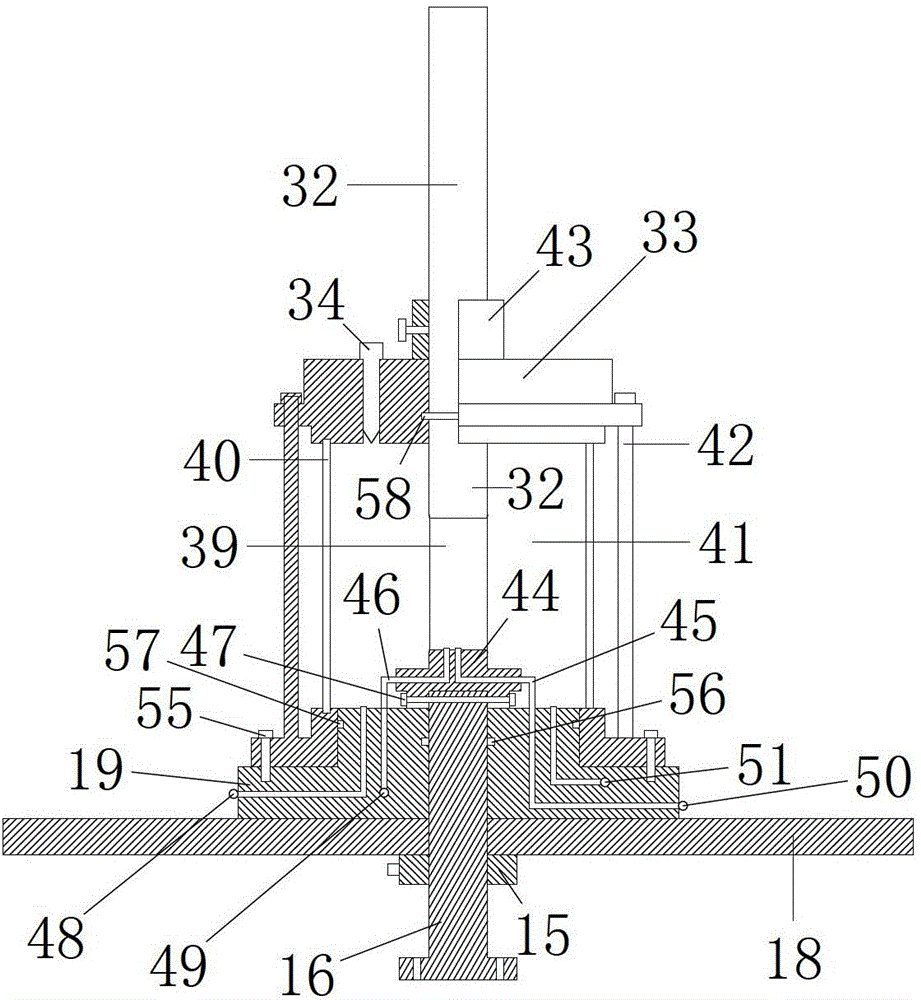

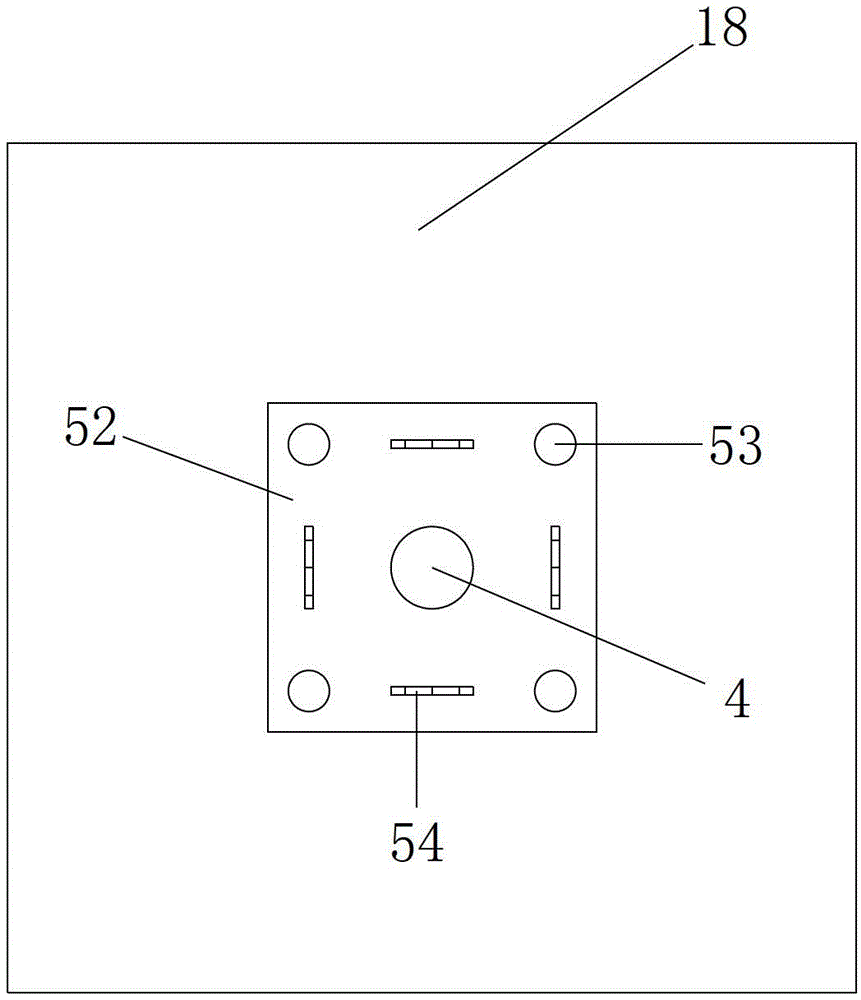

[0034] The structure of the device of the present invention is, as figure 1 , figure 2 As shown, it includes a box body 2. The box body 2 is arranged on the upper surface of the base 1. A motor platform 3 is installed in the box body 2. A liftable torque motor 4 is installed at the center of the motor platform 3. The torque motor 4 and the torque motor control 5 signal connection, the left instrument platform 6 and the right instrument platform 7 are respectively fixed on both sides inside the box body 2, the upper and lower surfaces of the left instrument platform 6 are respectively installed with a confining water supply and drainage controller 13 and The angular displacement display instrument 8 is equipped with a torque display instrument 14 at the end of the left instrument platform 6; a confining pressure loading measuring instrument ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com