Cut-off filter

A technology that cuts off light and incident light. It is applied in the direction of filters, etc., which can solve the problems of accumulation of light energy loss, aggravation of temperature rise, light energy loss, and light energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

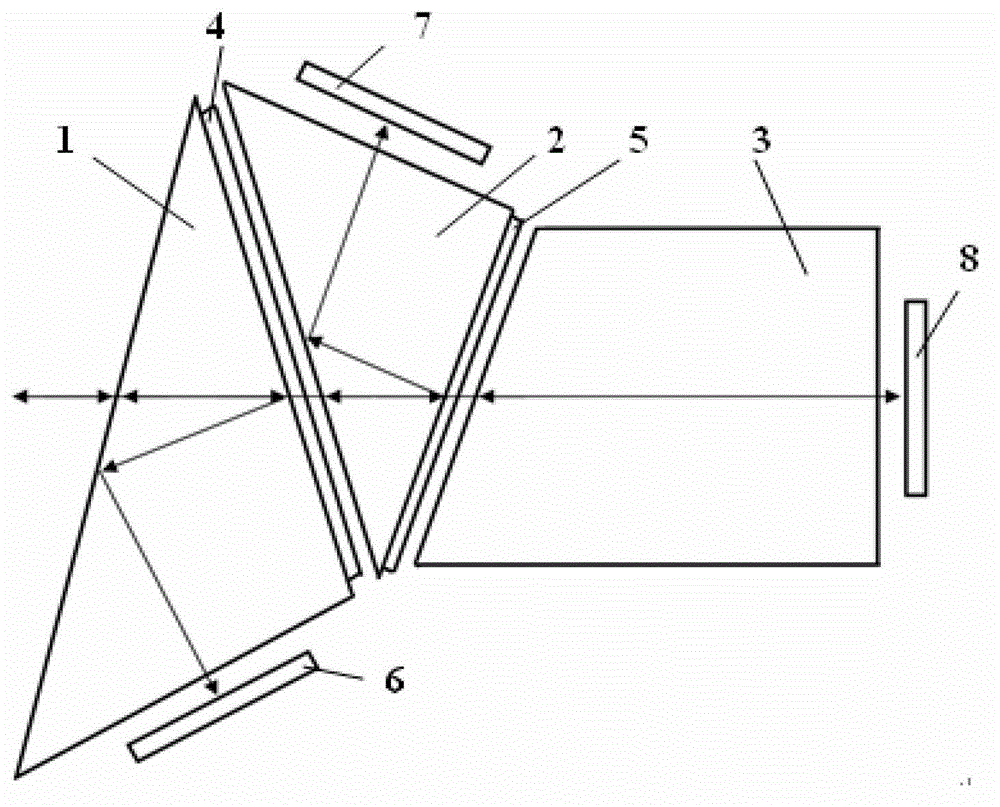

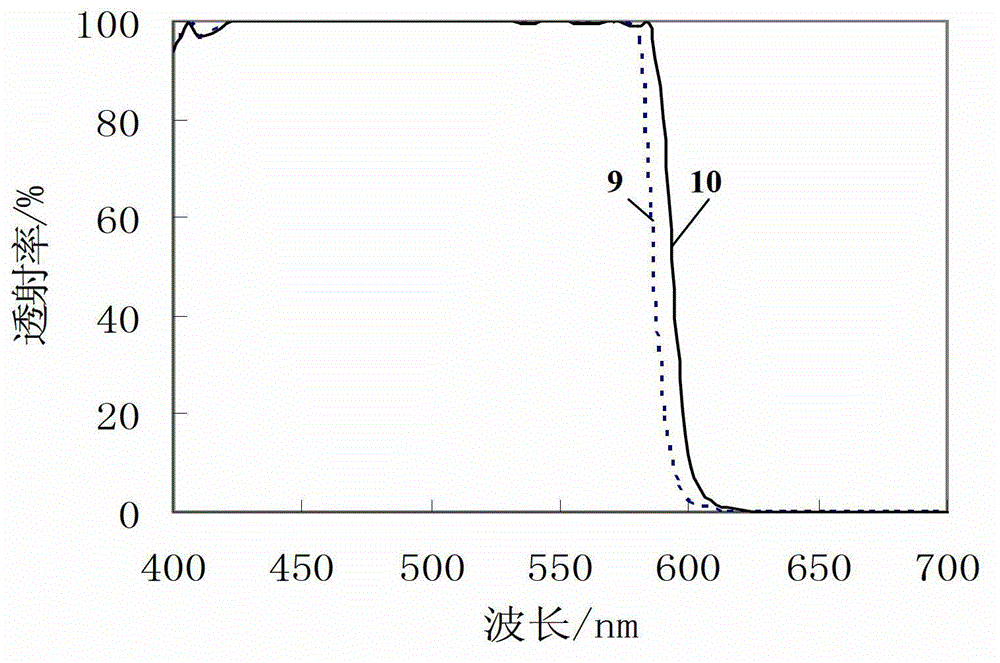

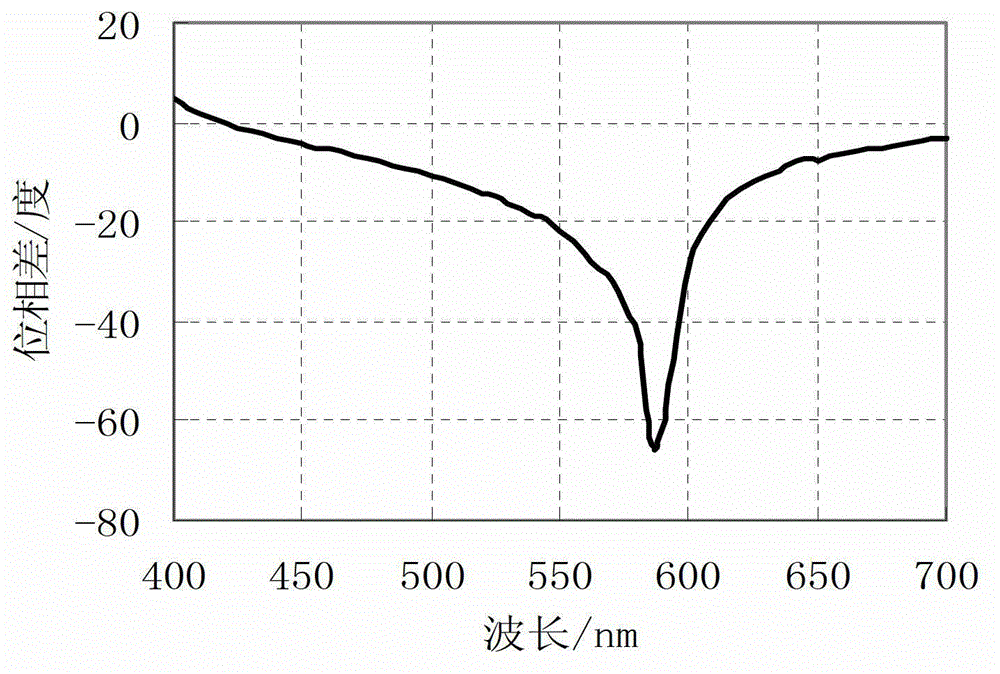

[0039] Such as figure 1 As shown, it is an existing color separation and color image synthesis system for projection display, including a first prism 1, a second prism 2, and a third prism 3 arranged along the direction of the optical path, the first prism 1 and the second prism 2 are triangular prisms, The section of the first prism 1 perpendicular to the edge is triangular, the section of the second prism 2 perpendicular to the edge is also triangular, and the oblique side of the first prism 1 (that is, the plane where the longest side of the section triangle is located, also called the first prism surface) as the incident surface of light, one side of the first prism 1

[0040] (that is, the plane where the middle side length of the cross-sectional triangle is located, also known as the second prism surface) is coated with a short-wave pass filter 4 that is anti-red, blue-green, and on the other side of the first prism 1 (that is, the shortest in the cross-sectional triangl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com