Processing device

A technology of processing device and positioning device, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

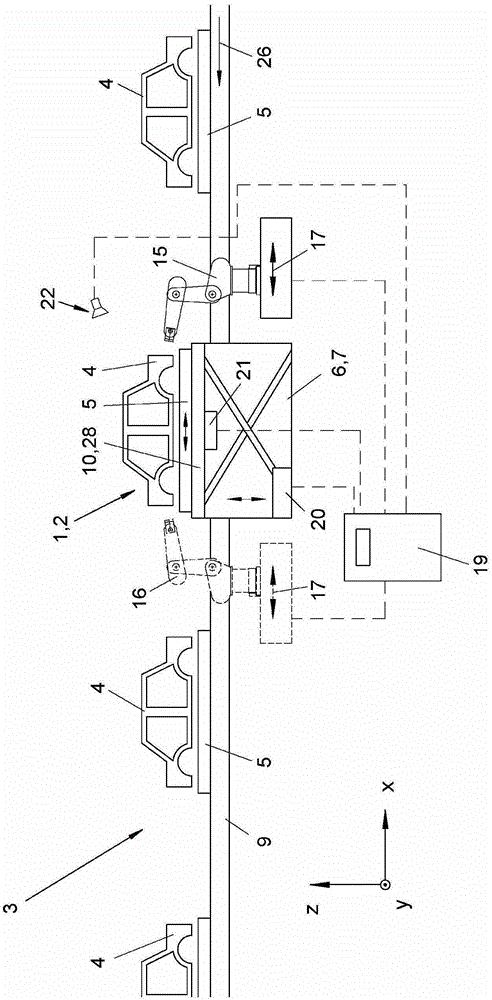

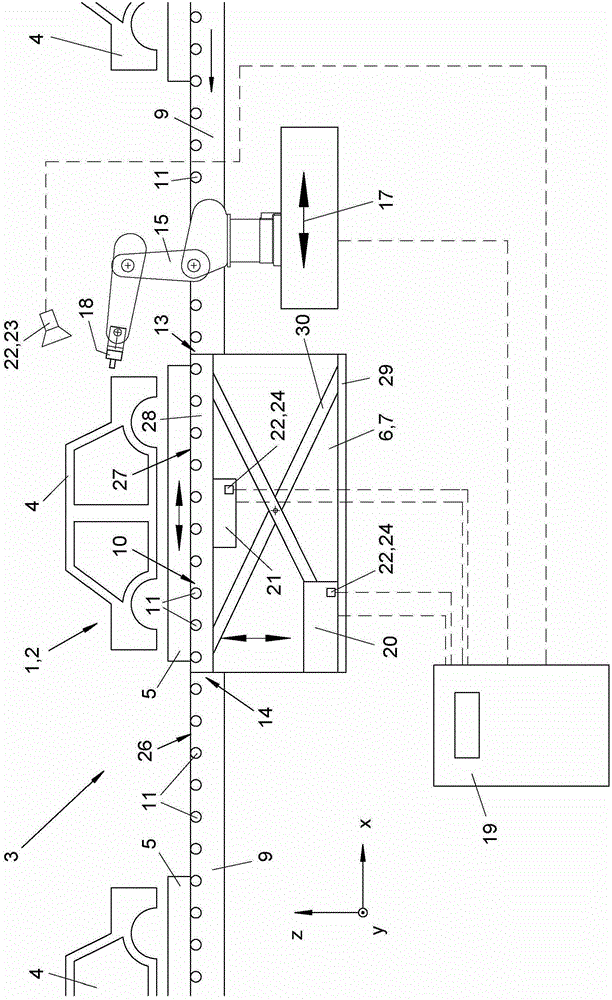

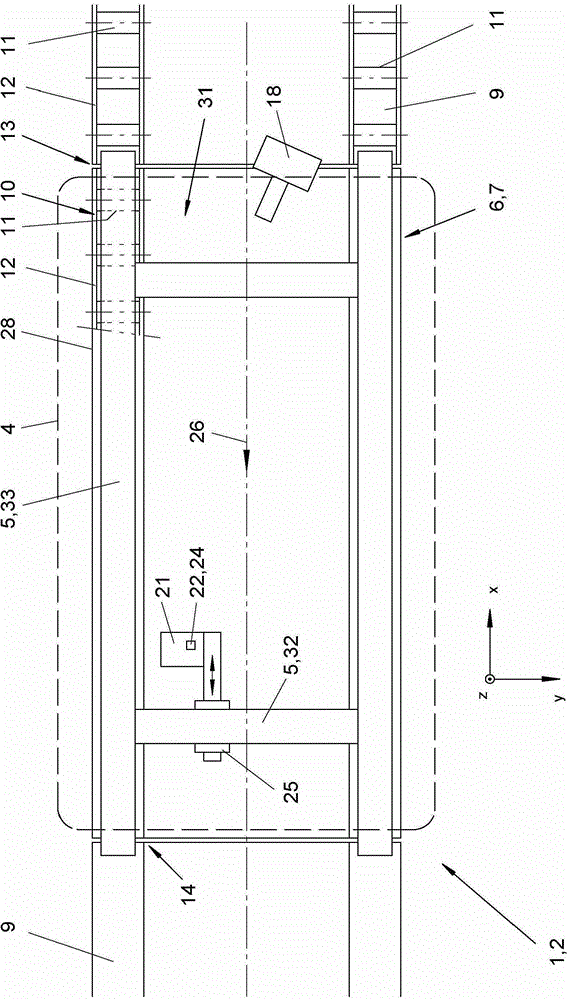

[0055] The invention relates to a machining device 1 for workpieces 4 . Furthermore, the invention relates to a processing method and a positioning method as well as to a processing plant with one or more processing devices 1 which can be integrated in the plant, for example as a processing table 2,

[0056] The workpiece 4 can be of any type and size, preferably a sheet metal part, in particular an automotive part. These vehicle parts can be body parts of the body-in-white, which are present, for example, in the form of individual or combined parts, such as underbody components, side wall components, and the like. The workpiece 4 may also be composed of body-in-white joined into a cubic shape.

[0057] One or more workpieces 4 can be arranged on the workpiece carrier 5 and held there in predetermined positions, and these workpieces are held and protected, for example, by means of clamps or the like. The workpiece carrier 5 can, for example, be arranged in the form of a plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com