Ladder inclined-surface reflection type condenser

A concentrator and reflective technology, which is applied in the field of solar energy, can solve the problems of secondary development of remaining energy, energy waste, and limited solar energy utilization, and achieve the effects of simple structure, energy saving, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

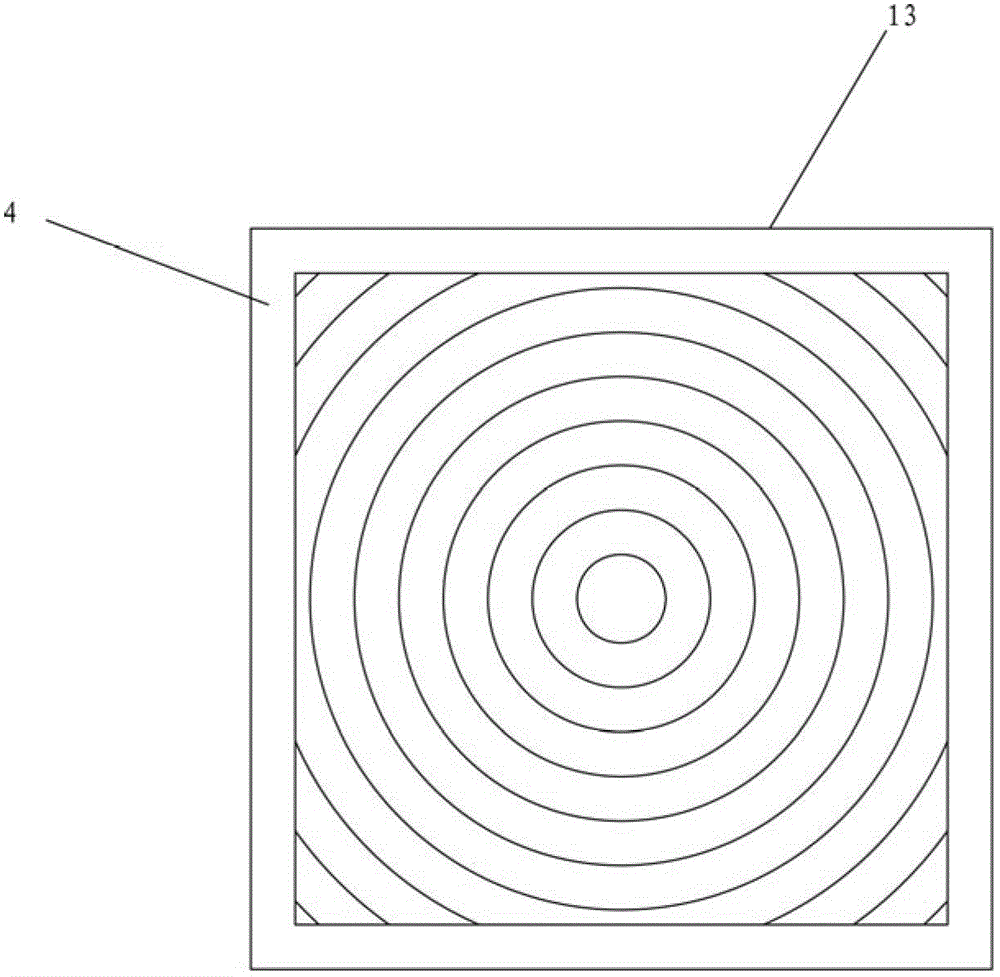

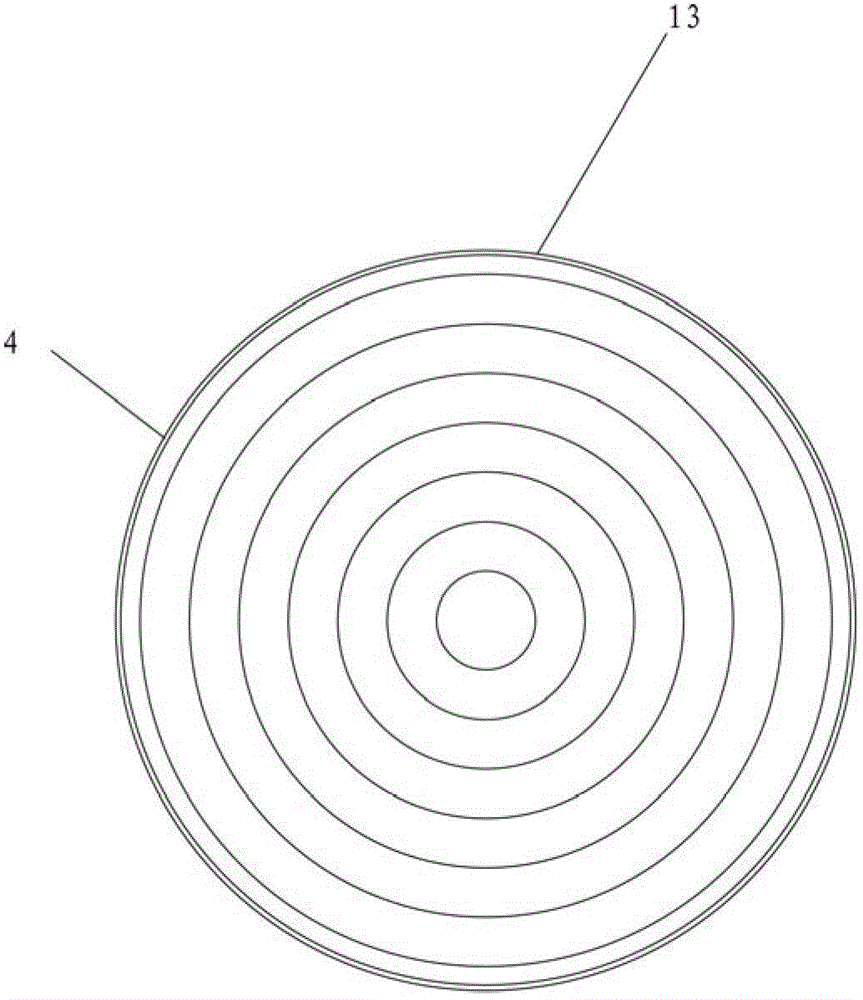

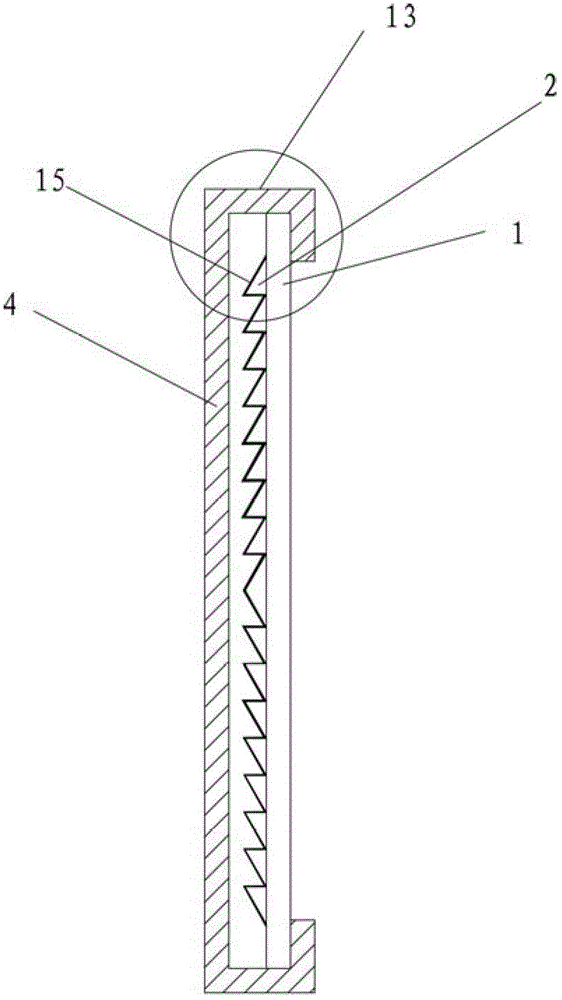

[0021] See image 3 , The present invention provides a stepped inclined surface reflection type condenser, including an outer frame 4 and a condenser 13 arranged in the outer frame 4. The condenser 13 includes glass 1, moulded on the glass 1 and located on the outer frame 4 and the glass Molded silica gel reflector unit 2 between 1; the outer frame 4 solidly seals the molded silica gel reflector unit 2 and the glass 1 from the side; the molded silica gel reflector unit 2 includes a plurality of concentric circles distributed with different slopes of molded silica gel reflector slopes and Reflective film 15 coated on the reflective bevel of molded silica gel; multiple reflective bevels can reflect and concentrate sunlight on a circular plane with a diameter smaller than the outermost reflective bevel; glass 1 is ultra-white flat tempered glass; Frame 4 is round or rectangular;

[0022] See Figure 5 , The present invention provides a step-slope reflection type condenser, comprisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com