LED lamps

A technology of light-emitting diodes and lamps, which is applied in the direction of light sources, electric light sources, and electric lamp circuit layout, etc., can solve the problems of inability to meet requirements, difficult control of afterglow circuits, and difficult design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention discloses a light emitting diode lamp, wherein the principle of the light emitting diode used has been understood by those skilled in the art, so the following description will not be fully described. At the same time, it is stated in advance that the drawings compared below are schematic structural representations related to the features of the present invention, and are not and need not be completely drawn according to actual dimensions.

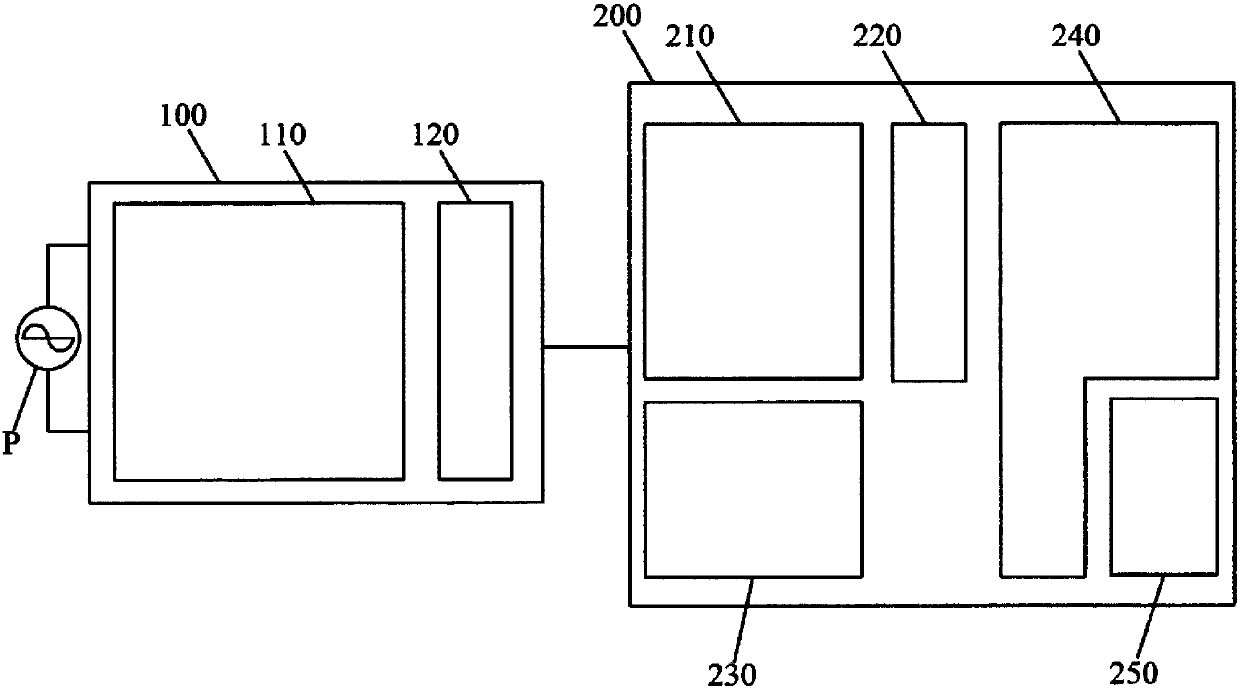

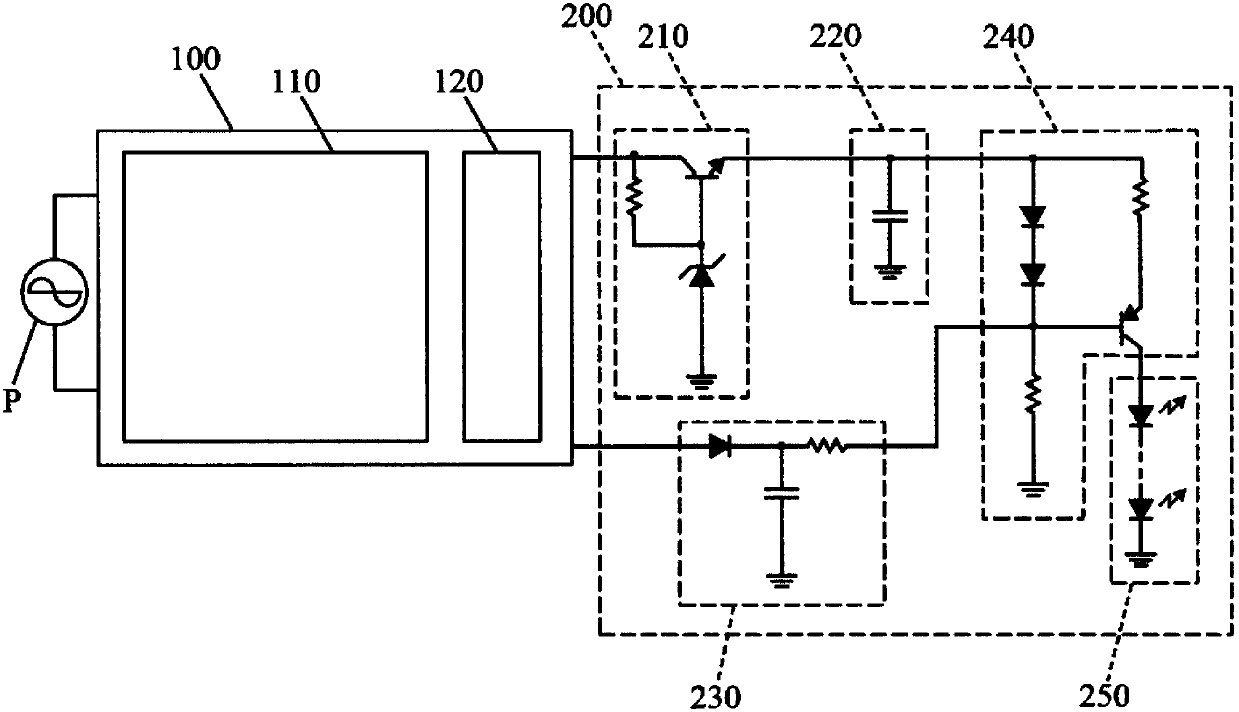

[0042] Please refer to figure 2 It is a structural block diagram of the light-emitting diode lamp proposed by the present invention. The LED lamp of the present invention comprises a main lighting circuit module 100 and an afterglow circuit module 200 electrically connected to the main lighting circuit module 100 .

[0043] The components constituting the aforementioned main lighting circuit module 100 include a main lighting driving device 110 and a main lighting load 120 . The main lighting load 120 is electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com