Biochemical decontamination agent and preparation method thereof

A decontamination and biochemical technology, applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of strong corrosion of equipment, large pollution, and low metal corrosion, and achieve low metal corrosion and drugs. The effect of low residue and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] All component raw materials are crossed 80 mesh sieves respectively, 25kg sodium carbonate and 28kg sodium percarbonate after sieving are stirred 1 hour under the condition of 20 ℃, normal pressure, relative humidity 40, wherein the mixer speed is 100 rev / mins, Obtain mixture 1; add 21kg of sieved dibromohydantoin, 20kg of bromochlorohydantoin, and 6kg of sodium polyacrylate with a molecular weight of 5,000 to mixture 1 in sequence, and stir at 20°C, normal pressure, and relative humidity of 40 2 hours, wherein the stirrer rotating speed is 500 revs / min, namely obtains the biochemical decontamination agent of the present invention. Based on the total mass of the decontamination agent as 100%, the mass percentages of each component are as follows: 21% of dibromohydantoin, 20% of bromochlorohydantoin, 6% of sodium polyacrylate, and 25% of sodium carbonate , Sodium percarbonate is 28%.

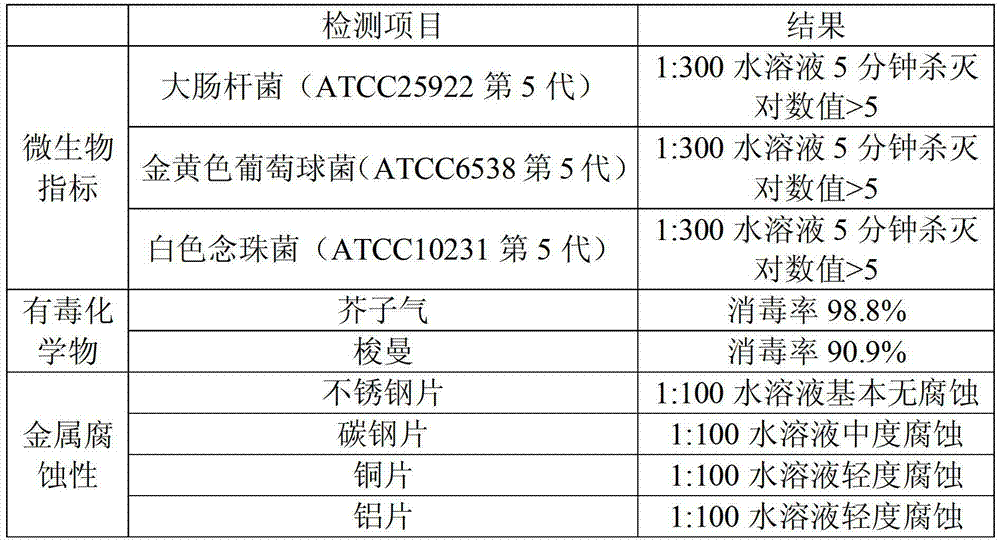

[0023] Described decontaminant is detected, and detection result is as follows:

[0...

Embodiment 2

[0028] All component raw materials are crossed 80 mesh sieves respectively, 30kg sodium carbonate and 20kg sodium percarbonate after sieving are stirred 1 hour under the condition of 21 ℃, normal pressure, relative humidity 40, wherein the speed of agitator is 100 rev / mins, Obtain mixture 1; 25kg dibromohydantoin, 15.5kg bromochlorohydantoin, 3kg sodium dodecylsulfonate, and 6.5kg sodium polyacrylate with a molecular weight of 5000 were added to mixture 1 in turn after sieving, and the mixture was heated at 21° C. , normal pressure, and 40 relative humidity conditions and stirred for 2 hours, wherein the stirrer speed was 500 rpm, to obtain the biochemical decontaminant of the present invention. Based on the total mass of the decontaminant as 100%, the mass percentages of each component are as follows: 25% dibromohydantoin, 15.5% bromochlorohydantoin, 3% sodium dodecylsulfonate, poly Sodium acrylate is 6.5%, sodium carbonate is 30%, and sodium percarbonate is 20%.

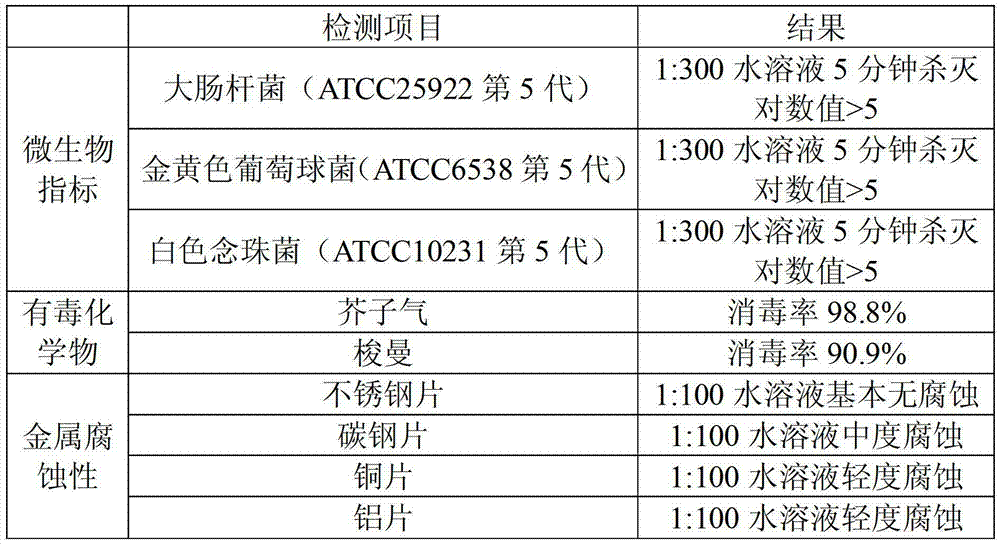

[0029] De...

Embodiment 3

[0034] All component raw materials are crossed 90 mesh sieves respectively, 24kg sodium carbonate and 30kg sodium percarbonate after sieving are stirred 1 hour under the condition of 22 ℃, normal pressure, relative humidity 40, wherein the speed of agitator is 100 rev / mins, Obtain mixture 1; 10kg dibromohydantoin, 30kg bromochlorohydantoin, 2kg sodium dodecylsulfonate, and 4kg sodium polyacrylate with a molecular weight of 7000 were added to mixture 1 in turn after sieving, and at 22°C, normal pressure, relative humidity of 40 under the conditions of stirring for 2 hours, wherein the mixer speed is 500 rpm, that is, to obtain the biochemical decontamination agent of the present invention. Based on the total mass of the decontaminant as 100%, the mass percentages of each component are as follows: 10% dibromohydantoin, 30% bromochlorohydantoin, 2% sodium dodecylsulfonate, poly Sodium acrylate is 4%, sodium carbonate is 24%, and sodium percarbonate is 30%.

[0035] Described dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com