Preparing method for supported core-shell-structure catalyst for low-temperature fuel cell

A fuel cell, core-shell structure technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large nanoparticles and poor distribution, and achieve uniform particle size distribution and small particle size. diameter, the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Add a certain amount of deionized water and Pluronic F127 into 4 single-necked flasks, stir to completely dissolve F127, and the mass fraction of F127 in the solution is 1.0%.

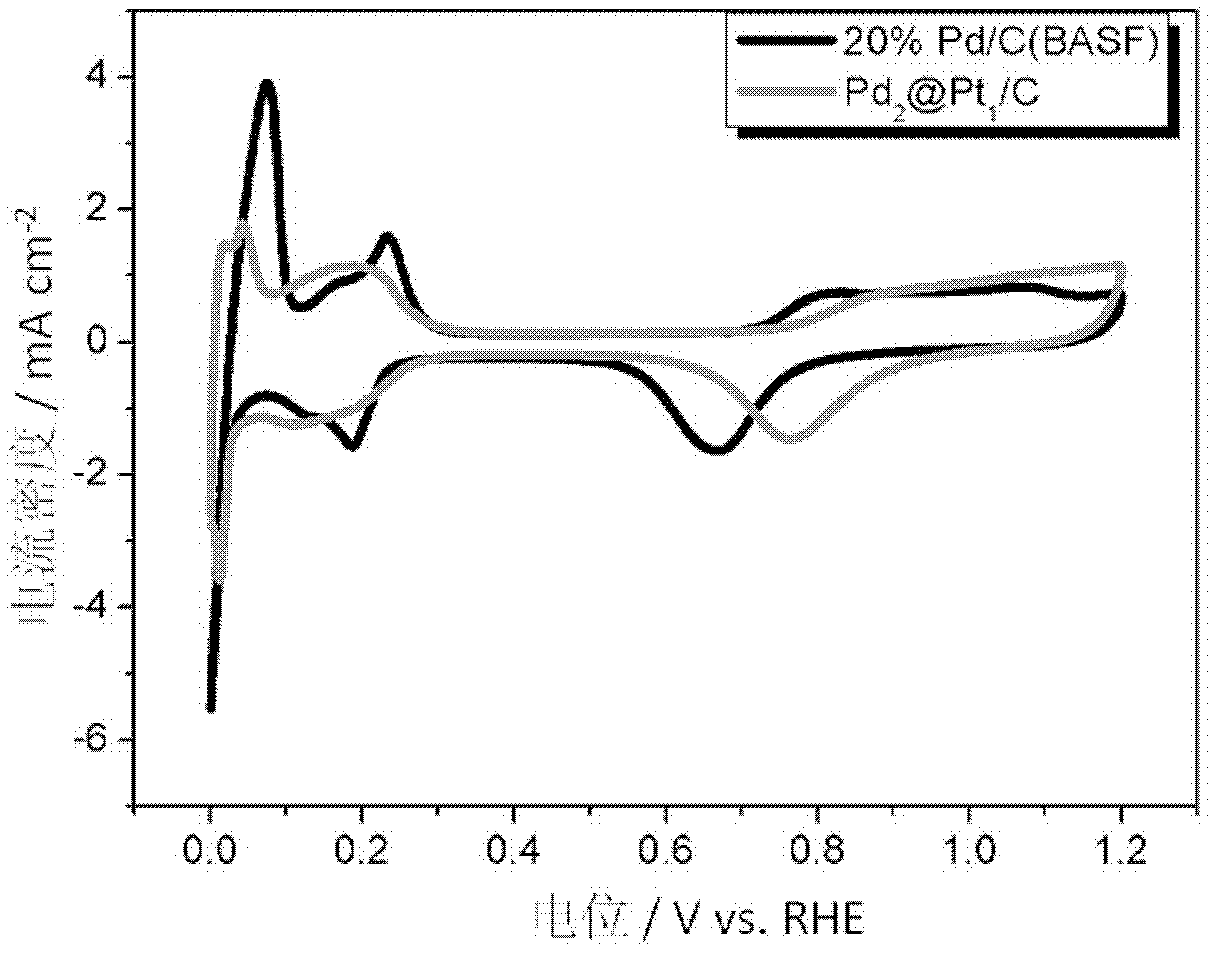

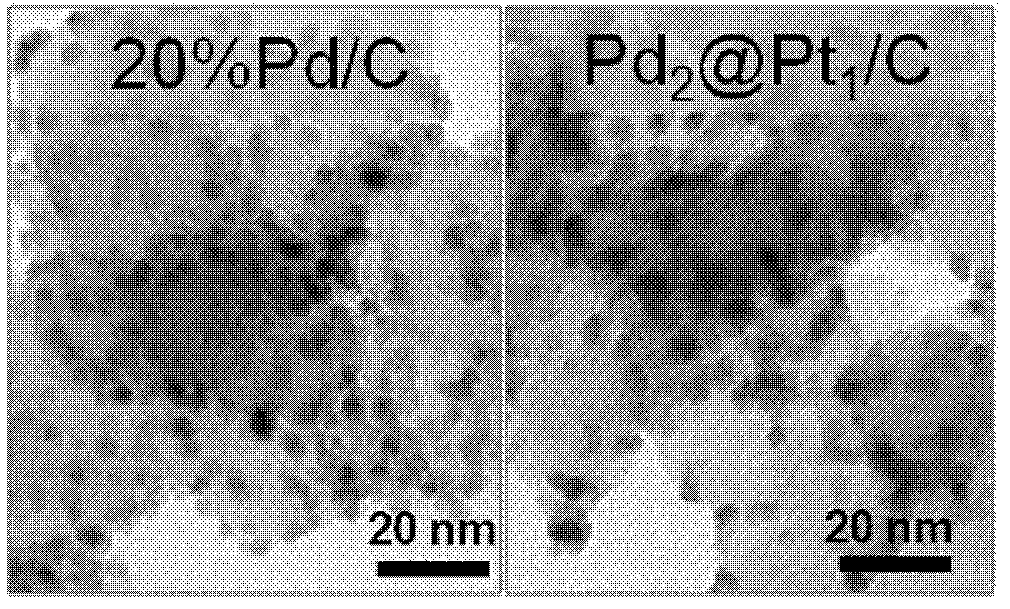

[0027] 2. Add 20% Pd / C (BASF) catalyst as the catalyst precursor to the above solution, so that the mass fraction of the catalyst precursor in the solution is 0.2%, stir and ultrasonically oscillate to make it uniformly dispersed.

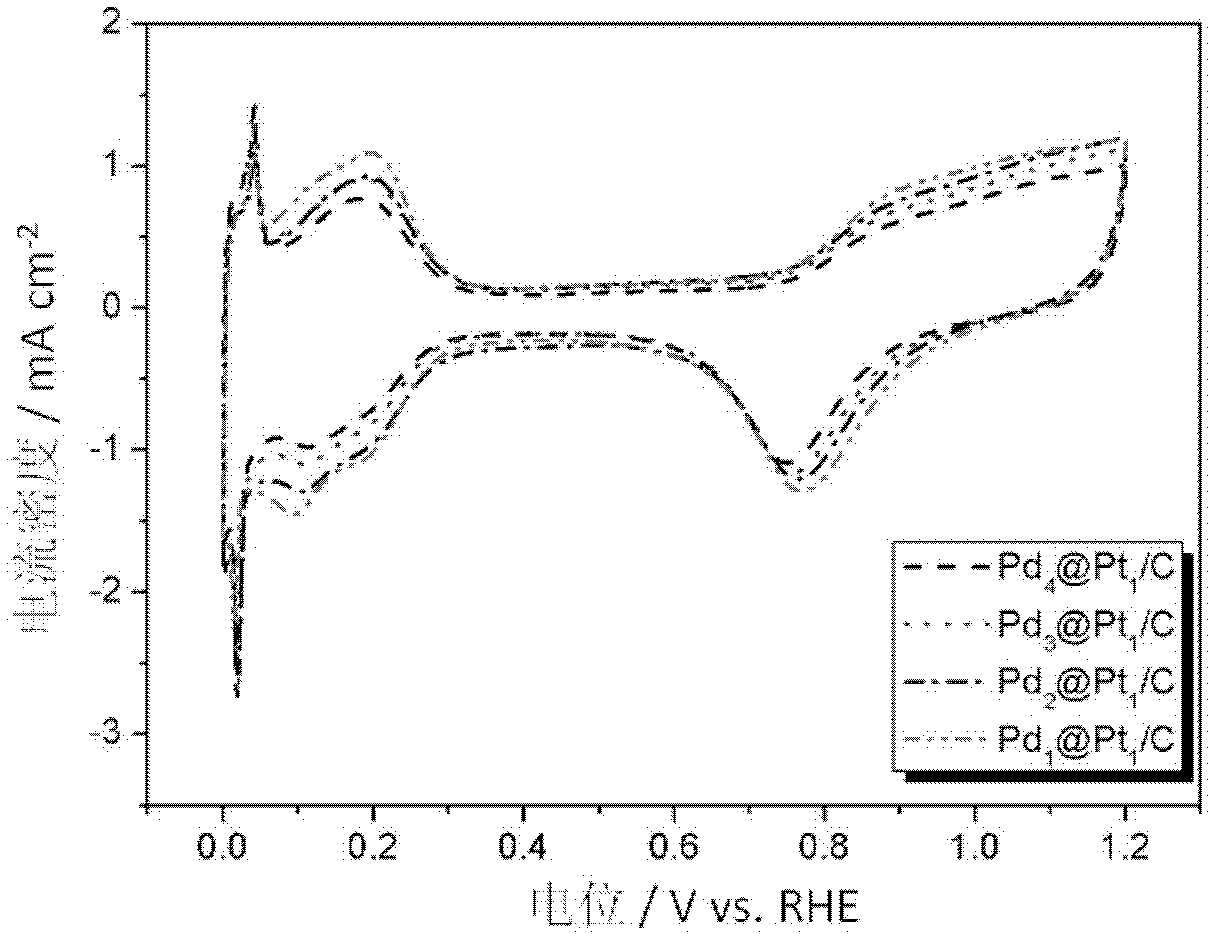

[0028] 3. Add K to the above suspension 2 PtCl 4 , So that the ratio of the amount of Pt to Pd is 1:4, 1:3, 1:2, 1:1, respectively, and stir to dissolve them all.

[0029] 4. Add ascorbic acid to the above suspension, so that the ratio of the amount of ascorbic acid to Pt / Pd is 1:4, 1:3, 1:2, 1:1. The ratios were respectively 33.3:1, 25.5:1, 17.2:1, 8.5:1, and then stirred at room temperature for 12 hours.

[0030] 5. After the reaction, centrifuged, washed with water 3 times, and then dried at 80°C under vacuum for 10 hours. Record the obtained catalyst as Pd 4 Pt 1 / C,...

Embodiment 2

[0035] 1. Add a certain amount of deionized water and cetyltrimethylammonium chloride (CTAC) into a single-neck flask, stir to completely dissolve CTAC, and the mass fraction of CTAC in the solution is 0.2%.

[0036] 2. Add 20% Au / C as the catalyst precursor to the above solution so that the mass fraction of the catalyst precursor in the solution is 0.5%, stir and ultrasonically oscillate to make it uniformly dispersed.

[0037] 3. Add H to the above suspension 2 PtCl 6 , So that the ratio of the amount of Pt to Pd is 1:1, and stir to dissolve them all.

[0038] 4. Add formic acid to the above suspension so that the ratio of the amount of formic acid to Pt is 200:1, and then let it stand at room temperature for 4 hours.

[0039] 5. Centrifugal separation after the reaction, washing several times, and then drying at 60°C under vacuum for 12h. Record the obtained catalyst as Au 1 Pt 1 / C.

[0040] This example obtains Au 1 Pt 1 The cyclic voltammetry curve of / C and 20%Au / C is as Figure...

Embodiment 3

[0042] 1. Add a certain amount of deionized water and Pluronic P123 into a single-neck flask, stir to completely dissolve P123, and the mass fraction of P123 in the solution is 0.5%.

[0043] 2. Add 20% Pd / C (BASF) catalyst as the catalyst precursor to the above solution, so that the mass fraction of the catalyst precursor in the solution is 1.0%, stir and ultrasonically oscillate to make it uniformly dispersed.

[0044] 3. Add K to the above suspension 2 PtCl 4 , So that the ratio of the amount of Pt to Pd is 1:2, and stir to dissolve them all.

[0045] 4. Add citric acid to the above suspension so that the ratio of the amount of citric acid to Pt is 100:1, and then stir at 100°C for 3 hours.

[0046] 5. Centrifugal separation after the completion of the reaction, washing several times, and then drying at 80°C under vacuum for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com