Filament winding device of thermoplasticity fiber composite belt

A technology of winding forming and winding devices, which is applied in the field of mechanical equipment, can solve the problems of little winding equipment involved, and achieve the effects of light weight, simple equipment, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

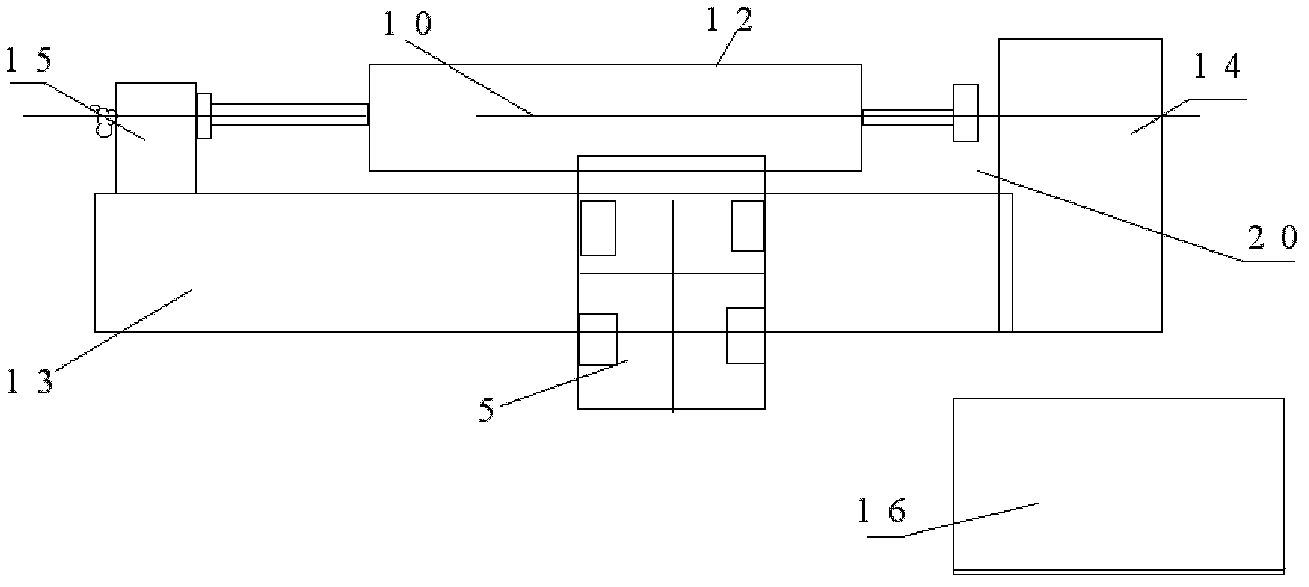

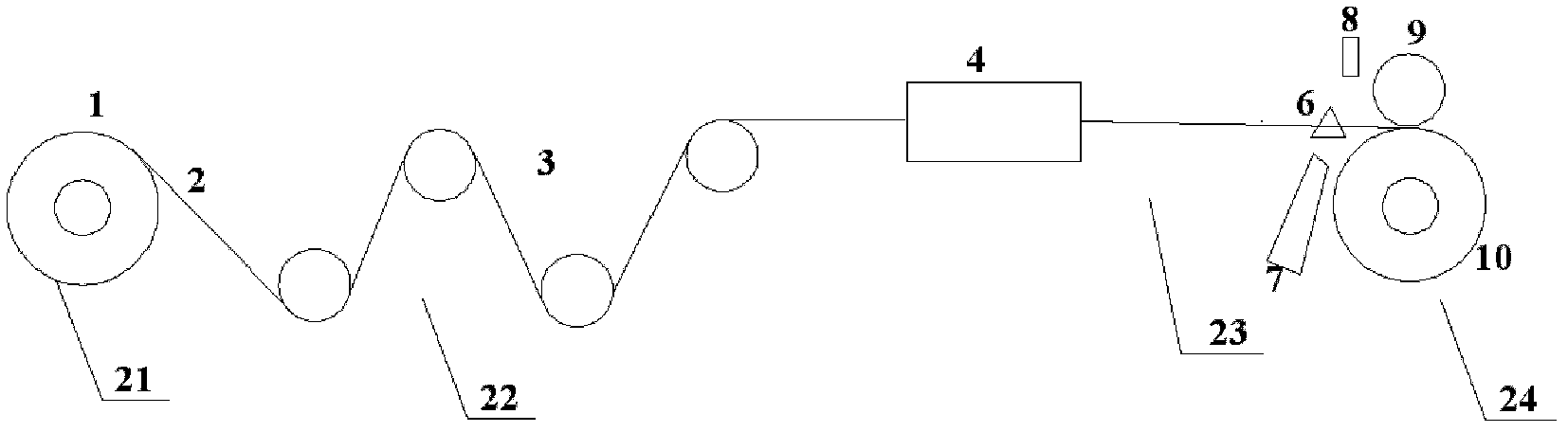

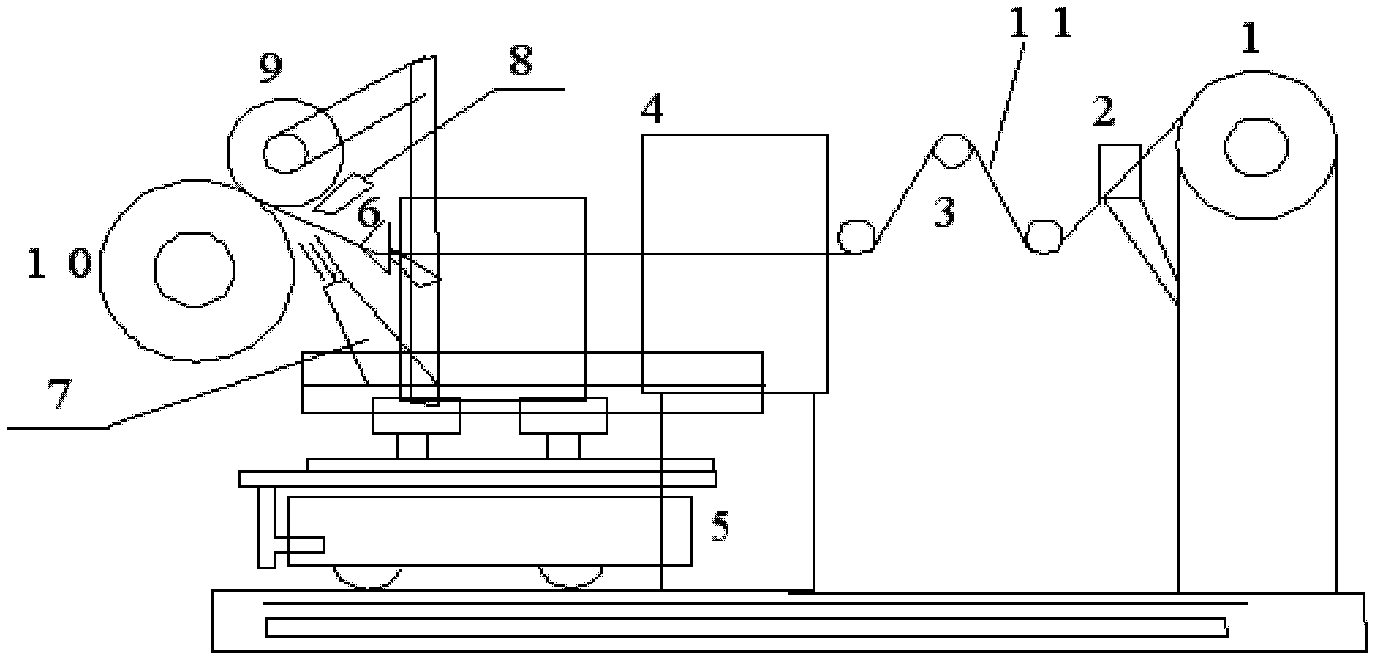

[0052] A device for thermoplastic composite tape winding as shown in the accompanying drawings and figure 2As shown, it includes two parts of a winding mechanical part 20 and a control system 16. The winding mechanical part 20 includes a winding device 21, a tension control device 22, and a winding device 24, and also includes a heating device 23. The heating device 23 is controlled by a preheating device. 4. The main heating device 7, the winding trolley 5, and the infrared thermometer 8 are composed. The pre-heating device 4 is located before the main heating device 7, and between the tension control device 22 and the main heating device 7. The main heating device 7 is located in the pre-heating device 4 and between the winding device 24.

[0053] The winding mechanical part 20 and the control system 16 are connected by connecting wires, the connecting wires are control wires or / and signal wires, and the winding mechanical part 20 is used for winding molding of thermoplasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com