Method for treating chromium-containing underground water with modified fly ash

A fly ash and groundwater technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of huge treatment equipment, high cost, low efficiency, etc., and achieve the treatment process Simple and economical, the effect of increasing porosity and enhancing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Modified fly ash of the present invention handles the method for chromium-containing groundwater, and its preferred embodiment is:

[0016] After the modified fly ash is added to the chromium-containing groundwater for reaction, the treated chromium-containing groundwater is obtained, and the modified fly ash is prepared through the following steps:

[0017] Weigh 20g of fly ash and add it to 140mL of sulfuric acid solution with a concentration of 0.5mol / L, modify at room temperature for 5 hours at a speed of 200r / min, wash with deionized water for 3 times, and dry at 105°C to obtain the modified Sexual fly ash.

[0018] Described sulfuric acid adopts the product of AR Sinopharm Group Chemical Reagent Beijing Co., Ltd.

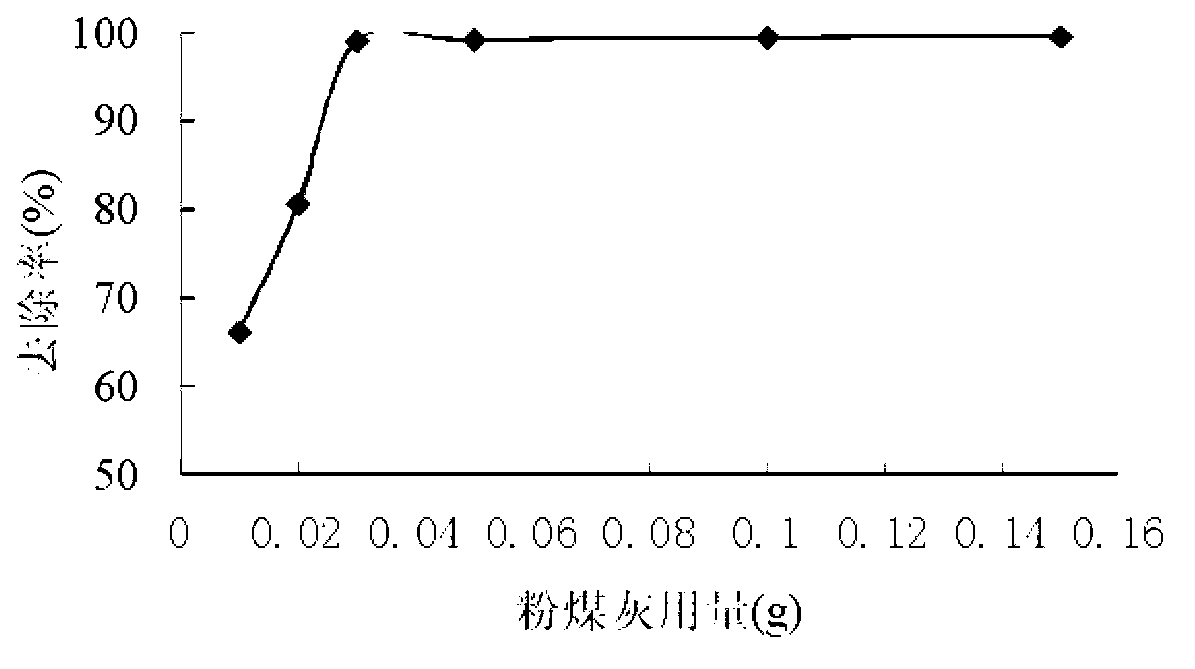

[0019] The chromium-containing concentration of the chromium-containing groundwater is 5 mg / L, and 0.03 g of the modified fly ash is added per 100 mL of chromium-containing groundwater, and reacted for 3 hours.

[0020] During the reaction, the temper...

Embodiment 1

[0023] Chromium (VI)-containing groundwater: simulated preparation with deionized water, accurately weigh 0.2829g of K 2 Cr 2 o 7 (bake at 120°C for 2 hours), transfer to a 1000mL volumetric flask, dilute to the mark, shake well, and store in a polyethylene bottle as a stock solution. Pipette 25mL into a 500mL volumetric flask, and shake to a constant volume to obtain a chromium (VI)-containing water sample with a concentration of 5mg / L.

[0024] Weigh different amounts of modified fly ash, add to 50mL water sample with chromium (VI) concentration of 5mg / L, shake at 25°C at a speed of 140r / min for a period of time, centrifuge and determine chromium (VI) ) concentration and calculate its removal rate.

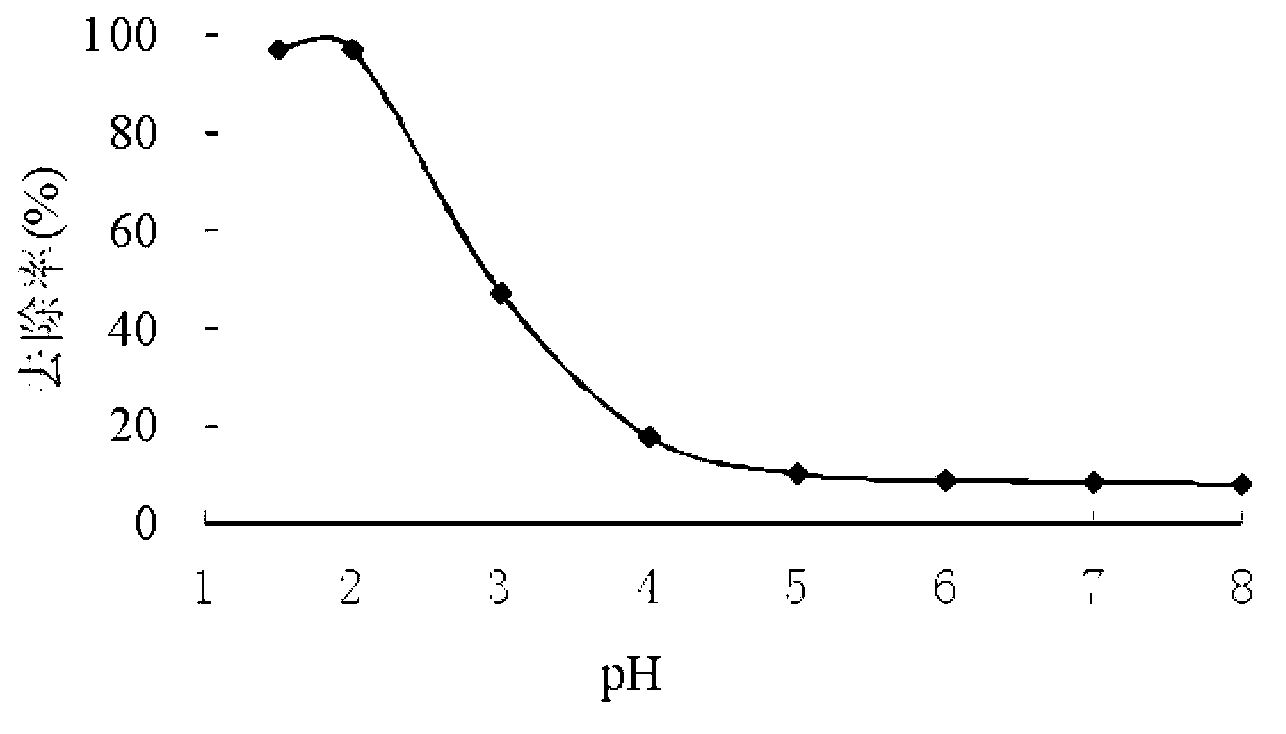

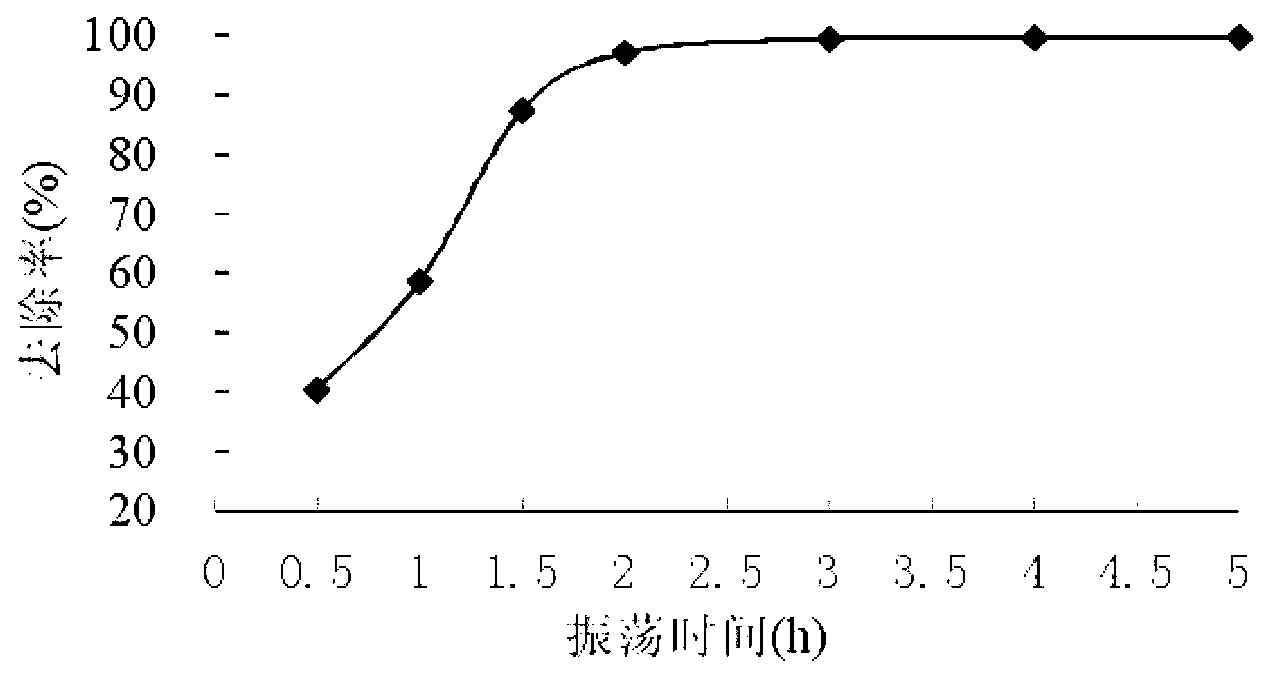

[0025] Use this material to treat water containing chromium (VI), pH=2 is appropriate ( figure 1 ), the best dosage is 0.03g of 100mL water sample ( image 3 ), reaction 3h ( figure 2 ), the removal rate of chromium (VI) can reach more than 99%, and the effluent can meet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com