A kind of external wall flame retardant thermal insulation decoration integrated board and preparation method thereof

A flame retardant thermal insulation, exterior wall technology, applied in covering/lining, construction, building structure, etc., can solve hidden dangers, external wall thermal insulation fall, warping safety and quality and other problems, achieve durable protection and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

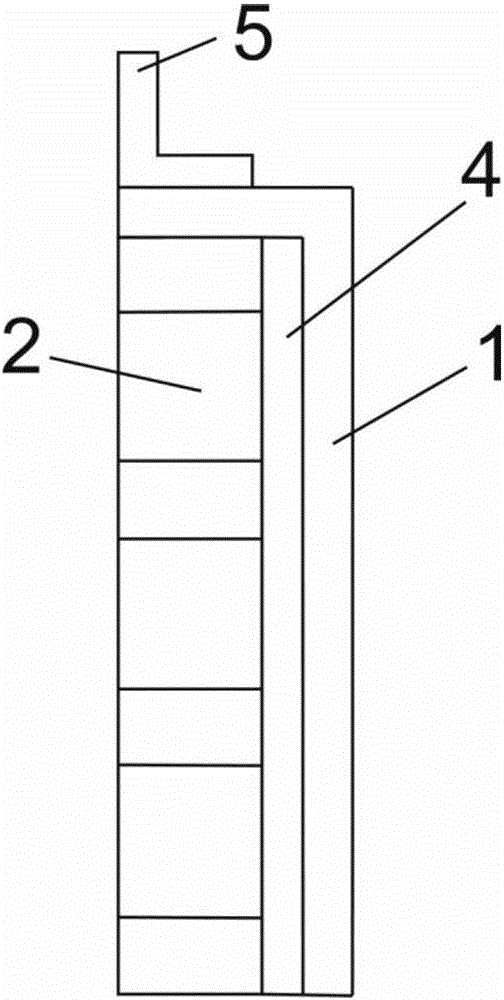

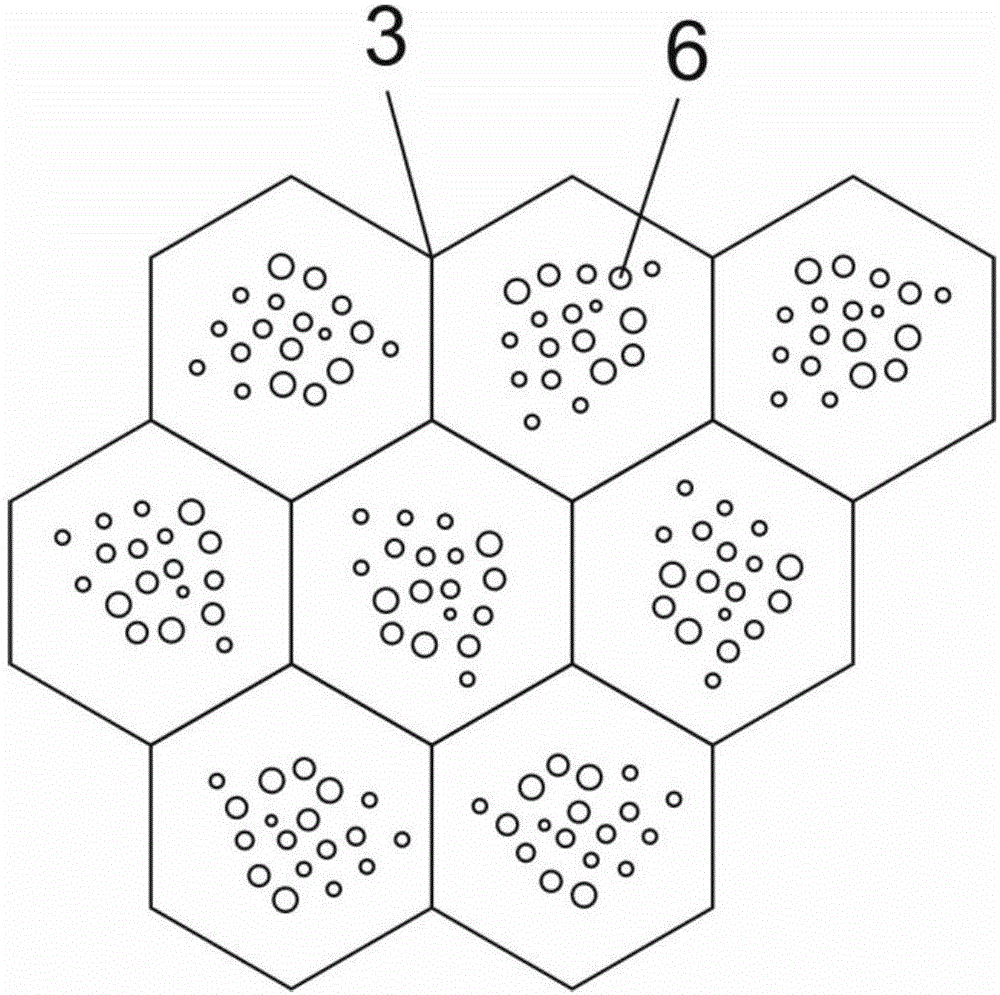

[0030] Dip the honeycomb paper into an inorganic flame-retardant glue made of 60% silicate solution or phenolic resin prepreg for 5 minutes, and then perform differential stretching to form a base core until each base core is positive Polygon; the stretched honeycomb paper is dried by microwave or drying equipment at 80℃ for 3 minutes for drying and setting; then, the inorganic resin protection board is laid on the bottom surface of the largest area of the metal veneer, and then the product Lay the base core on the surface of the cement pressure board, and finally spray and inject black and white foamed polyurethane raw materials on the laid components.

Embodiment 2

[0032] The honeycomb paper is immersed in a silicate solution with a mass concentration of 80% or an inorganic flame-retardant glue made from a phenolic resin prepreg for 4 minutes, and then differentially stretched to form a base core until each base core is positive Polygon; the stretched honeycomb paper is dried by microwave or drying equipment at 80℃ for 3 minutes for drying and setting; then lay calcium silicate board on the bottom surface of the largest area of the metal veneer, and then the product Lay the base core on the calcium silicate board surface, and finally spray and infuse the black and white foamed polyurethane raw materials on the laid components.

Embodiment 3

[0034] The honeycomb paper is immersed in a silicate solution with a mass concentration of 70% or an inorganic flame-retardant glue made of a phenolic resin prepreg for 2 minutes, and then differentially stretched to form a base core until each base core is positive Polygon; the stretched honeycomb paper is dried by microwave or drying equipment at 80℃ for 2.5 minutes for drying and shaping; then the glass magnesium board is laid on the bottom surface of the largest area of the metal veneer, and then the obtained The base core is laid on the surface of the glass magnesium board, and finally the black and white foamed polyurethane raw materials are sprayed and poured on the laid components.

[0035] The honeycomb structure of the flame-retardant and heat-insulating core material 2 in the present invention has high strength and light weight, and is also beneficial to sound insulation and heat insulation. Therefore, today's space shuttles, artificial satellites, and spacecraft use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com