Heat Exchanger Based on Turboexpander

A technology of a turboexpander and a heat exchange device, which is applied to the components of a pumping device for elastic fluids, mechanical equipment, machines/engines, etc. Disassembly and maintenance, compact structure, reducing the effect of axial heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

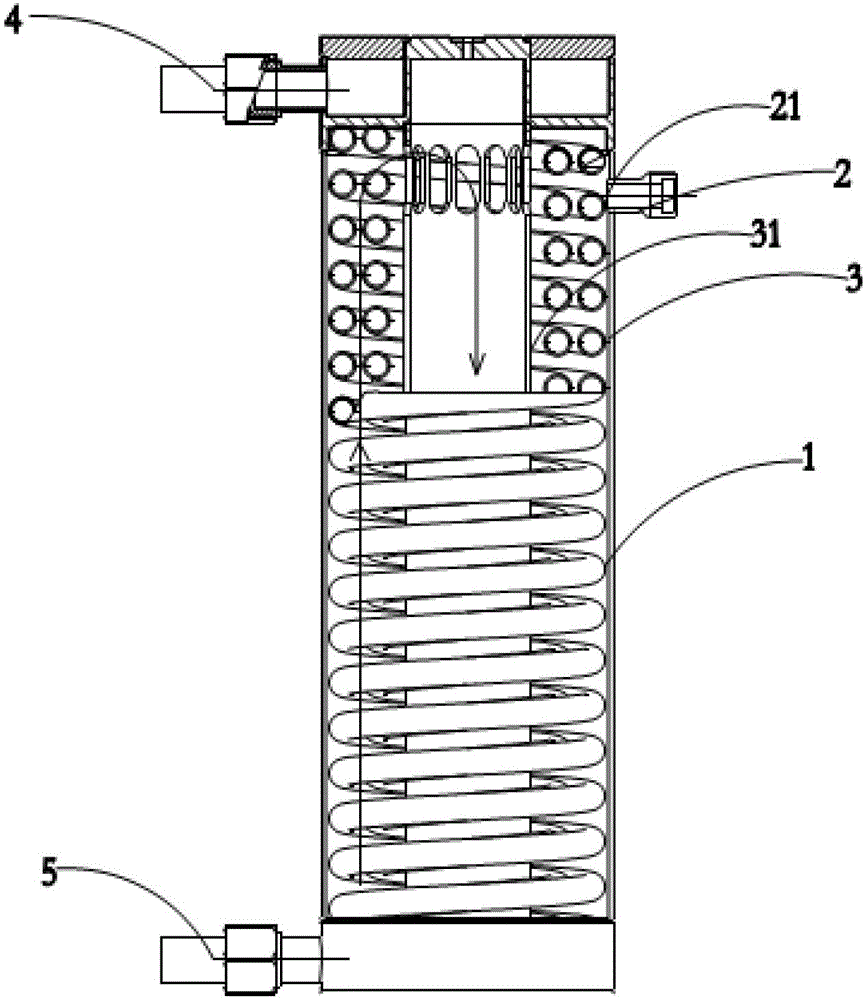

[0010] Such as figure 1 As shown, it is a schematic diagram of the heat exchanger of the heat exchange device based on the turbo expander of the present invention, including a brake fan (not marked), an air intake pipe 2, a cooling water inlet 4 and a cooling water outlet 5, and the brake fan includes The inner fan volute 3 and the outer fan wheel cover (not shown) arranged around the fan volute 3 also include an integrated heat exchanger 1 sleeved on the periphery of the fan wheel cover, and the heat exchanger 1 is connected to the fan wheel cover with a flange (not marked) and separated, and the flange includes a lower connecting flange connected to the heat exchanger 1 and an upper connecting flange connected to the fan wheel cover. The air intake pipe 2 is provided with an outer wall 21 , the fan volute 3 is provided with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com