Light-emitting diode (LED) panel lamp and manufacture method thereof

A technology of LED panel lamp and lampshade, which is applied in the cooling/heating device of lighting device, lighting and heating equipment, semiconductor device of light-emitting element, etc. Conducive to environmental protection, extended life, and low recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

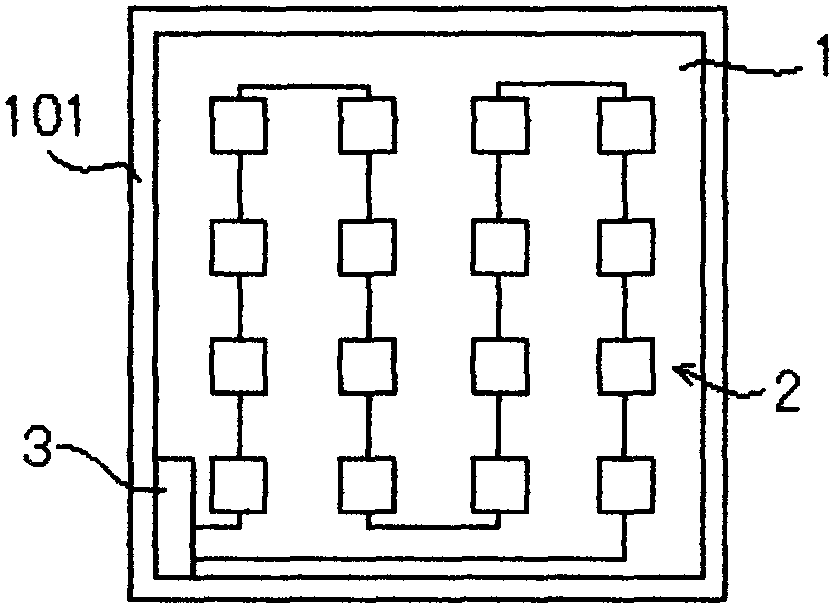

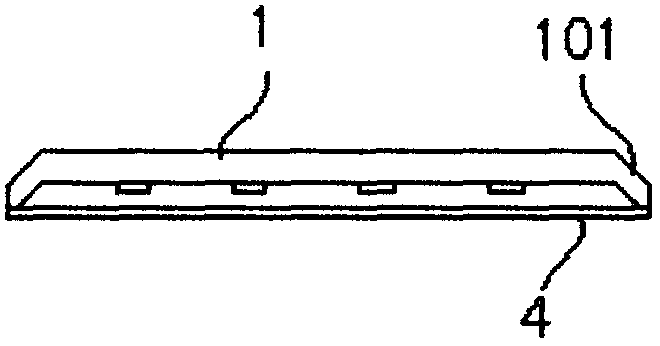

[0034] refer to figure 1 , figure 2 As shown, an LED panel lamp includes a base 1, an LED load circuit 2 connected in series or in parallel, and a lampshade 4 made of a light-transmitting material. The LED load circuit 2 and the lampshade 4 are connected to the base 1. The base 1 is an aluminum plate that doubles as a suspended ceiling, and the surface of the base 1 is coated with an insulating layer. The LED load circuit 2 is printed on the insulating layer, and a power adapter 3 is connected to both ends of the LED load circuit 2 . The LED load circuit 2 is composed of a circuit board and a number of LED light sources directly mounted on the circuit board in an SMT manner.

[0035] In this embodiment, a PC board is selected as the lampshade 4 . In order to fix the lampshade 4 and facilitate installation and disassembly, at least two edges of the base 1 are buckles 101 for fixing the lampshade 4 .

[0036] The power adapter 3 is fixed on the base 1 and placed on the same s...

Embodiment 2

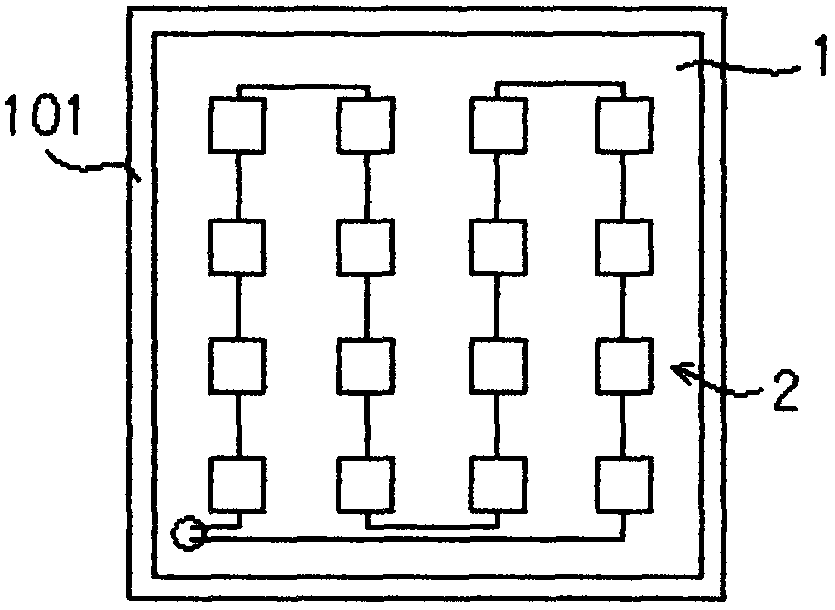

[0038] refer to image 3 , Figure 4 As shown, the rest is the same as that of Embodiment 1, the difference is that the power adapter 3 is fixed on the base 1 and placed on the back of the LED load circuit 2, and the base 1 is provided with an outlet hole so that Connect the LED load circuit 2 with the power adapter 3 .

[0039] A method for manufacturing an LED panel lamp, comprising the following steps:

[0040] Step 1) Printing a circuit board on an aluminum plate;

[0041] Step 2) A plurality of LED light sources are directly mounted on the circuit board in an SMT manner to form a parallel or series LED load circuit;

[0042] Step 3) Cut the aluminum plate according to actual needs to obtain a semi-finished LED panel light;

[0043] Step 4) Stamping the edge of the semi-finished LED panel light into buckles, and the precision of the stamping die is controlled within 0.1mm;

[0044] Step 5) installing a power adapter on the semi-finished LED panel light, the power adap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com