Combined type coal pulverizing system

A pulverizing system and composite technology, applied in the preparation of block/powder fuel, combustion method, combustion equipment, etc., can solve the problems of power plant safety impact, high power consumption of coal grinding, poor economy, etc., to avoid unnecessary problems. Safety factor, low power consumption for milling, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

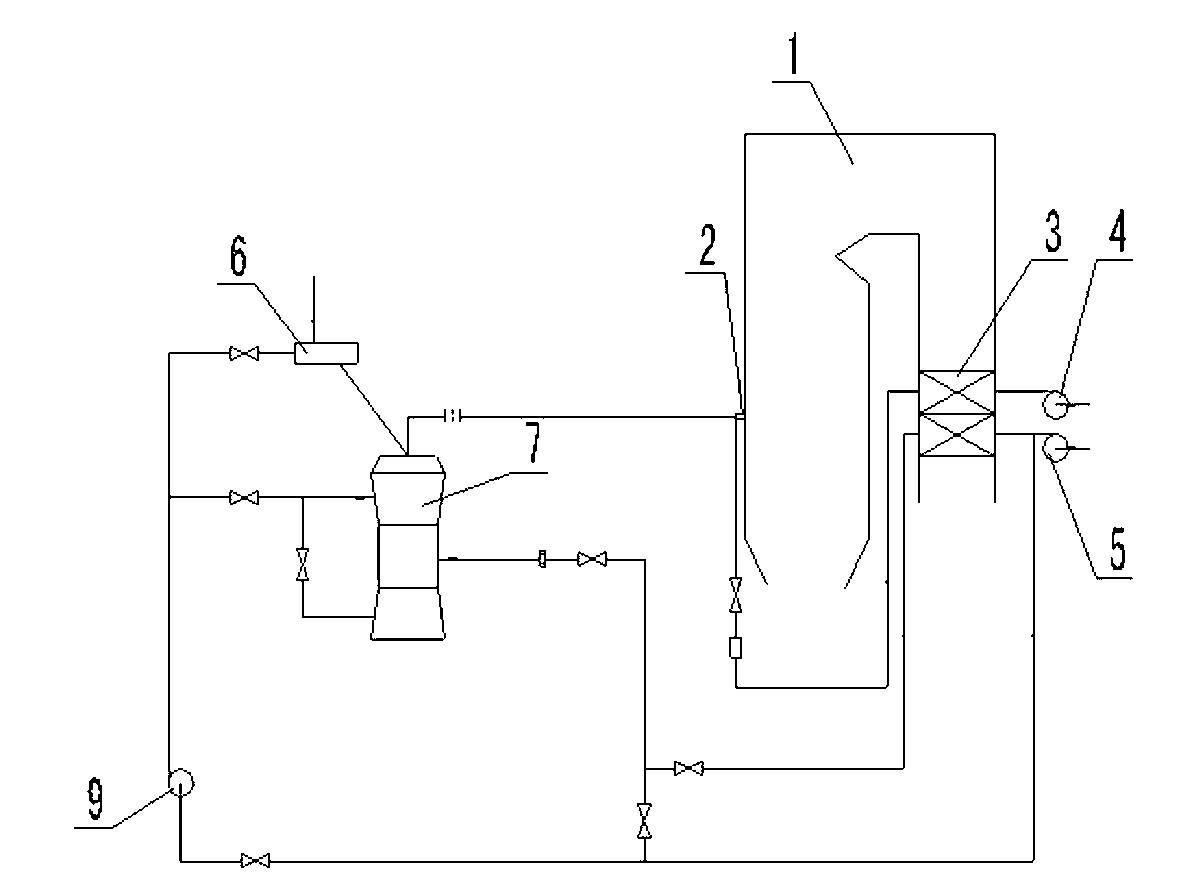

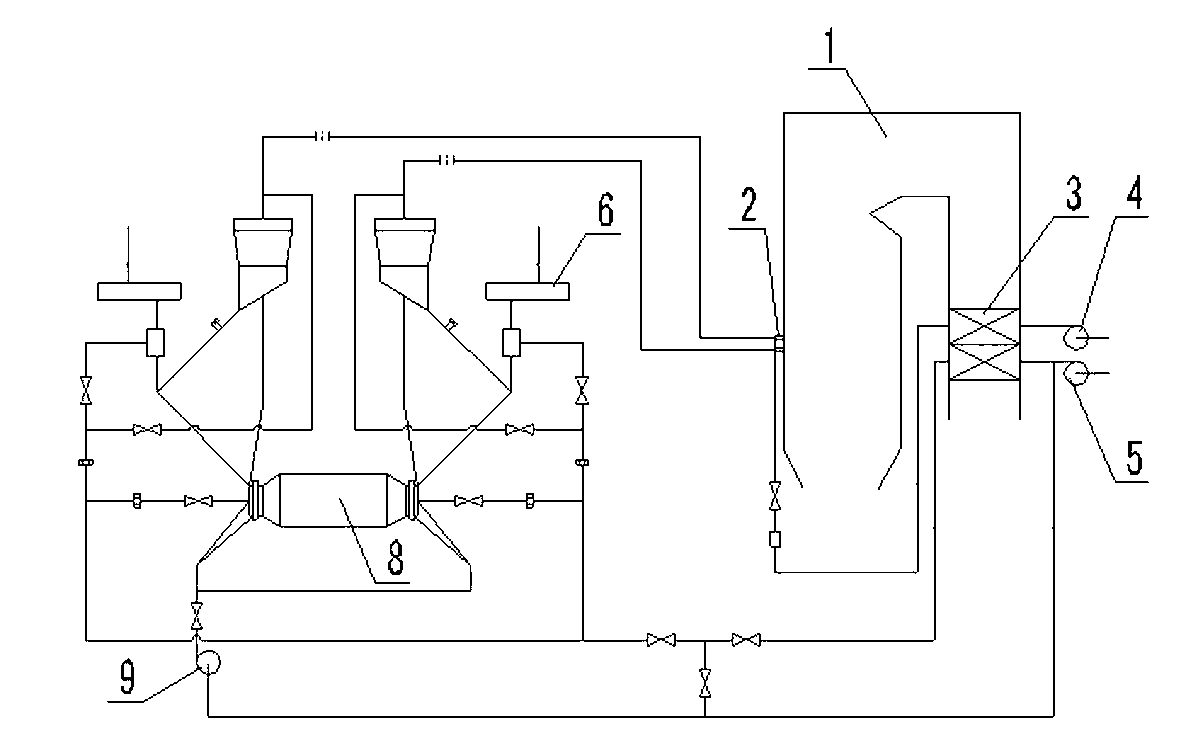

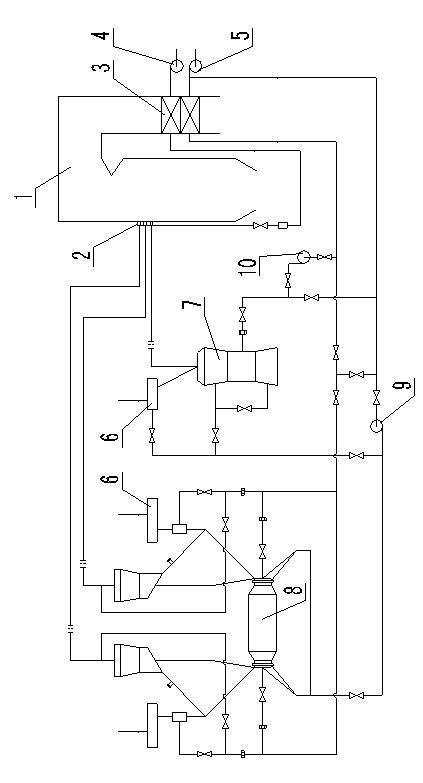

[0016] Such as image 3 As shown, the medium-speed coal mill direct-blown pulverization system and the double-inlet and double-outlet coal mill direct-blown pulverizer system are connected in parallel with boiler 1 and burner 2, that is, the coal feeder 6 coming out of boiler 1 is simultaneously Connect the medium-speed coal mill 7 and the double-inlet and double-outlet steel ball coal mill 8 to form a composite pulverizing system. Moreover, the boiler 1 is connected to the blower 4, the primary fan 5 and the sealing fan 9, and the sealing fan 9 is connected to the medium-speed pulverizer direct-blown pulverization system and the double-inlet and double-outlet coal pulverizer direct-blown pulverization system.

[0017] For the problem that the wind pressure of the medium-speed coal mill 7 needs to be higher than the wind pressure of the double-inlet and double-outlet steel ball coal mill 8, the present invention solves the problem by connecting a hot booster fan 10 to the medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com