Optic fiber monitoring device for shell component stress

A monitoring device and component technology, applied in the direction of measuring the force of change in optical properties of materials when they are under stress, can solve the problems of limited popularization, expensive monitoring equipment, difficult installation, etc., and achieve a wide range of uses and flexible use methods , The effect of convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

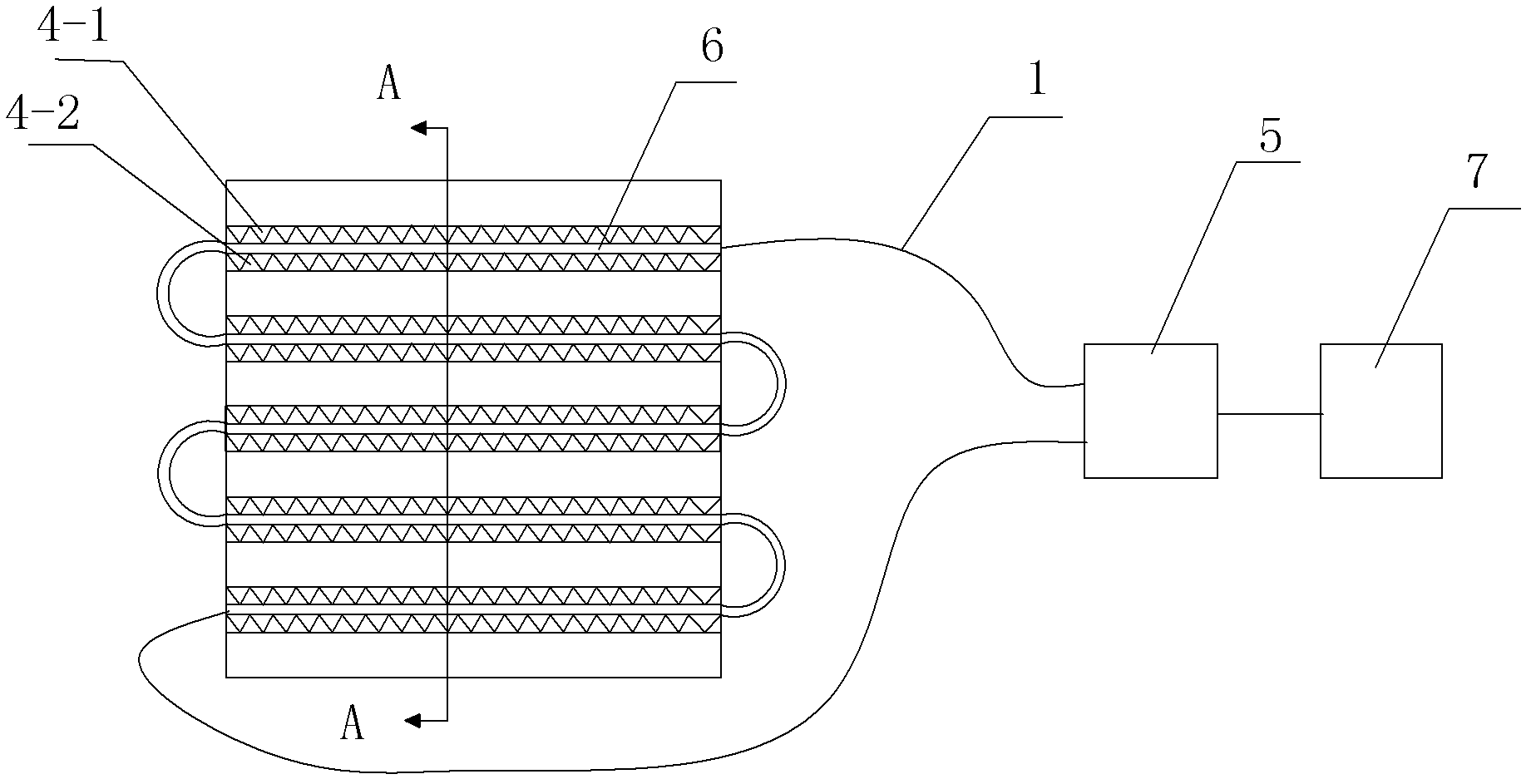

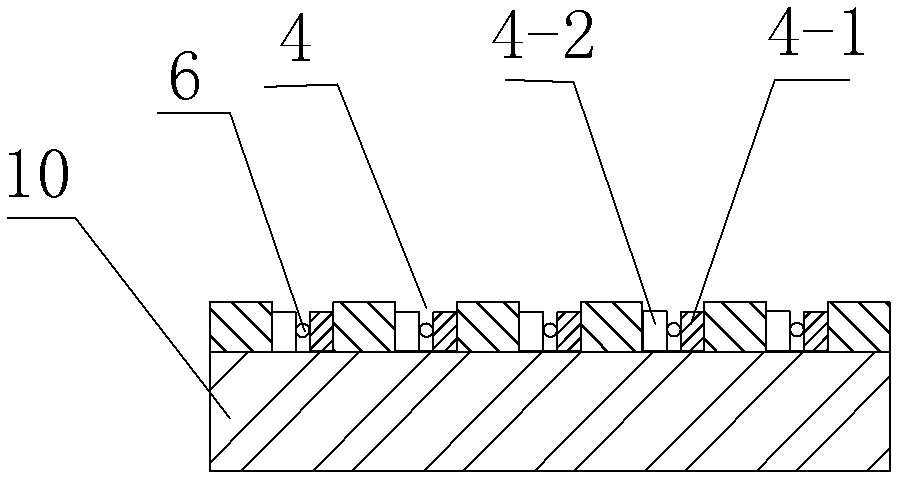

[0028] Such as figure 1 , figure 2 The shown optical fiber monitoring device for shell member stress includes a plurality of parallel first grooves 4 distributed on the shell member 10, and the opposite sides of the first groove 4 have respectively staggered and corresponding A-side deformations. The tooth 4-1 and the B-side deformed tooth 4-2, and the first signal optical fiber 6 is sandwiched between the A-side deformed tooth 4-1 and the B-side deformed tooth 4-2 on the opposite sides of the first groove 4. A signal optical fiber 6 is connected to the test unit 5 through the extension fiber 1 , and the processing unit 7 is connected behind the test unit 5 .

[0029] When the deformation of the shell member 10 widens or narrows the width of the first groove 4, the distance between the deformed teeth on the opposite sides of the first groove 4 will also become larger or smaller, so that the clip The bending curvature of the first signal optical fiber 6 held between the defo...

Embodiment 2

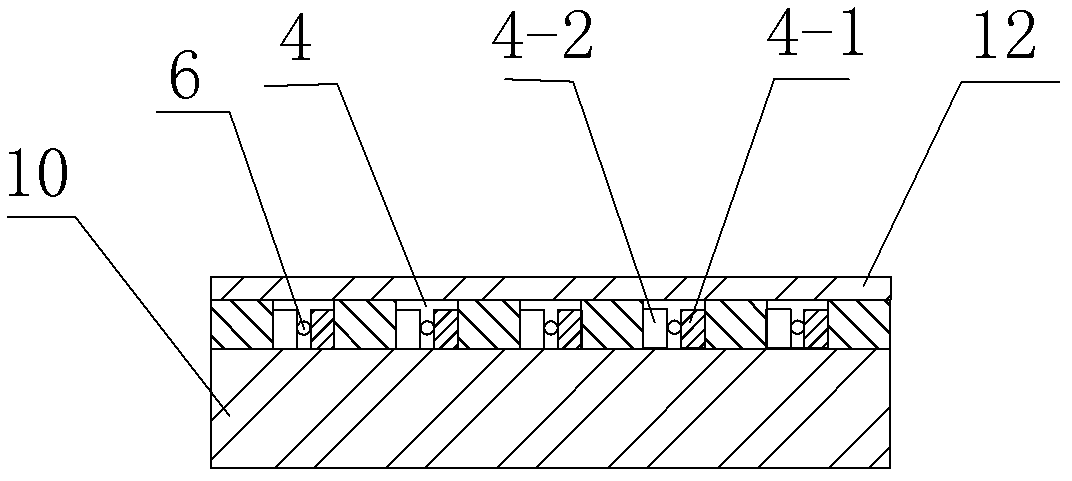

[0038] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that: the first groove 4 is covered with a protective skin 12 to prevent external damage to the first signal optical fiber 6 . In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0040] Such as Figure 4 , Figure 5 and Figure 6 As shown, in this embodiment, the difference from Embodiment 1 is that the upper and lower surfaces of the shell member 10 are respectively provided with a first groove 4 and a second groove 9, and there are mutual grooves on the opposite sides of the two grooves. The A-side deformed teeth 4-1 and B-side deformed teeth 4-2 are staggered, and the first signal optical fiber 6 and the second signal optical fiber 8 are sandwiched between them, and the first groove 4 and the second groove 9 are at 90 degrees Angle, so that any deformation of the shell member 10 can be monitored.

[0041] In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com