Low-carbon aluminum-containing silicon steel standard sample and its preparation method

A standard sample, aluminum-silicon technology, applied in the field of chemical analysis, can solve the problems of lagging scientific research and production technology, restricting new analysis methods, etc., and achieve the effect of compact structure, reducing the scrap rate of silicon steel, and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution involved in the present invention will be further described below in conjunction with specific examples, but it is not intended to limit the content of the invention.

[0042] The spectral standard sample of silicon steel among the present invention is the chemical element that evenly contains following weight percent in silicon steel smelting process steel:

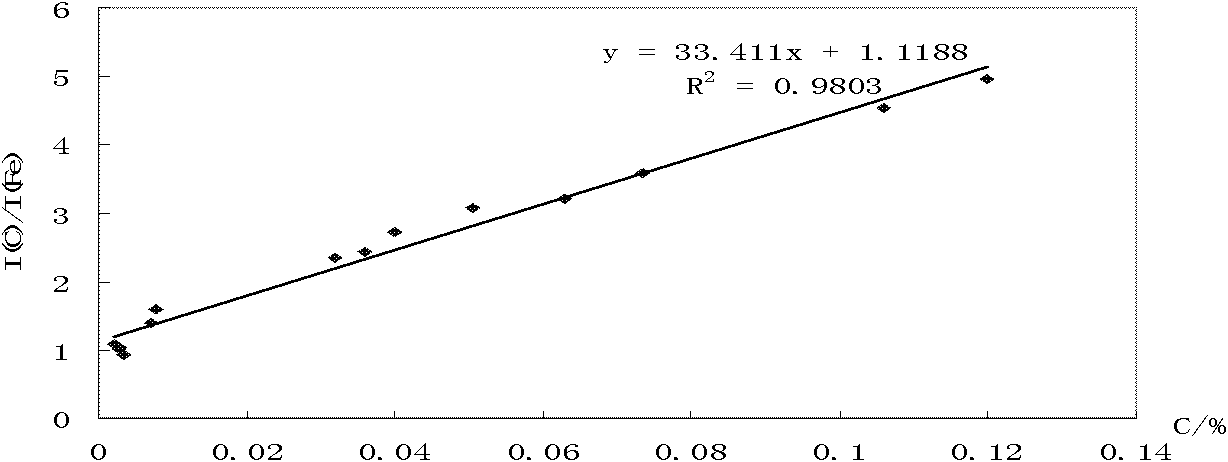

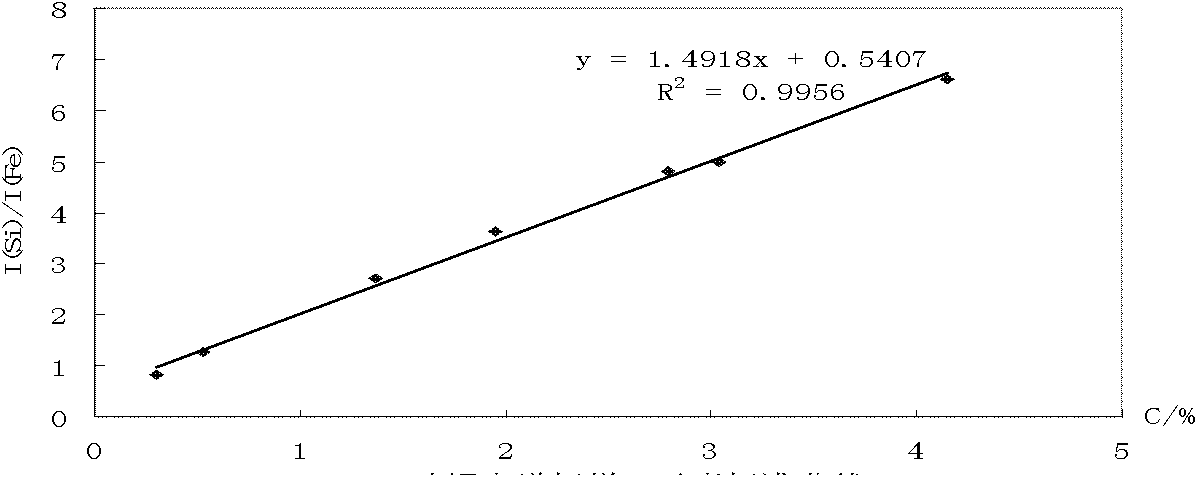

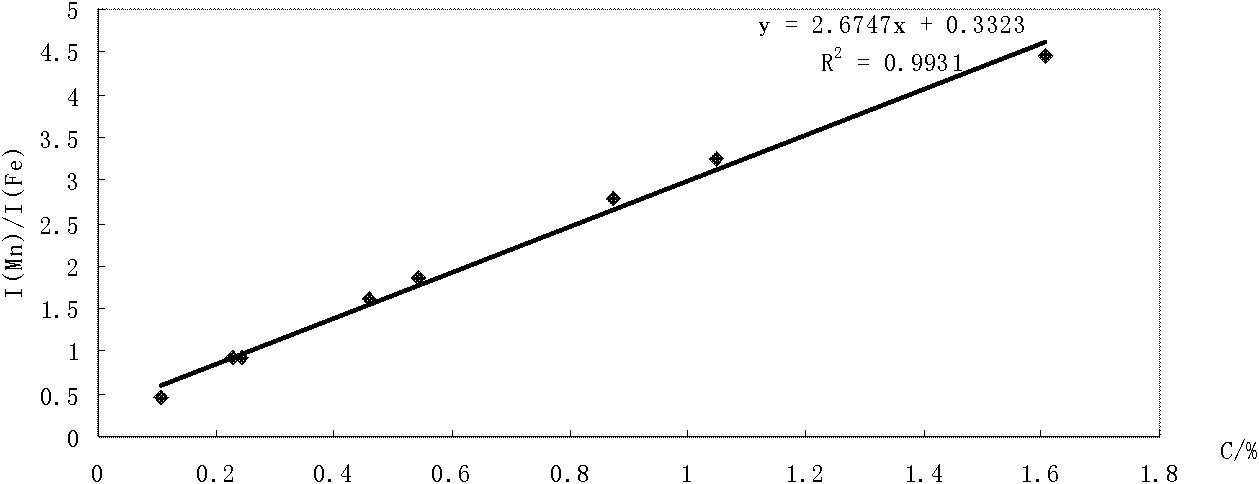

[0043]C: 0.0022% to 0.0735%, Si: 0.300% to 4.195%, Mn: 0.105% to 1.605%, P: 0.0072% to 0.111%, S: 0.0018% to 0.0214%, Ni: 0.0031% to 0.131%, Cr: 0.0142%~0.400%, Cu: 0.0037%~0.252%, V: 0.0006%~0.0019%, Ti: 0.0019%~0.0545%, Alt: 0.0253%~0.535%, Bt: 0.0001%~0.0014%, As: 0.0009% ~0.0014%, Sb: 0.0002%~0.0035%, Sn: 0.0001%~0.0002%, Nb: 0.0012%~0.0301%, N: 0.0016%~0.0004%, and the balance is iron element and unavoidable impurities.

[0044] Summary table of total weight percentage of chemical elements in silicon steel spectral standard sample GG1#~GG8# (ω%)

[0045]

[0046] The preparation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com