Hydraulic device with high pressure and large flow rate for rapid boosting

A hydraulic device and large flow technology, applied in the field of hydraulic devices, can solve problems such as rapid solidification of liquid metal, uneven product forming, failure to meet design requirements, etc., and achieve the effects of short pressurization time, easy installation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

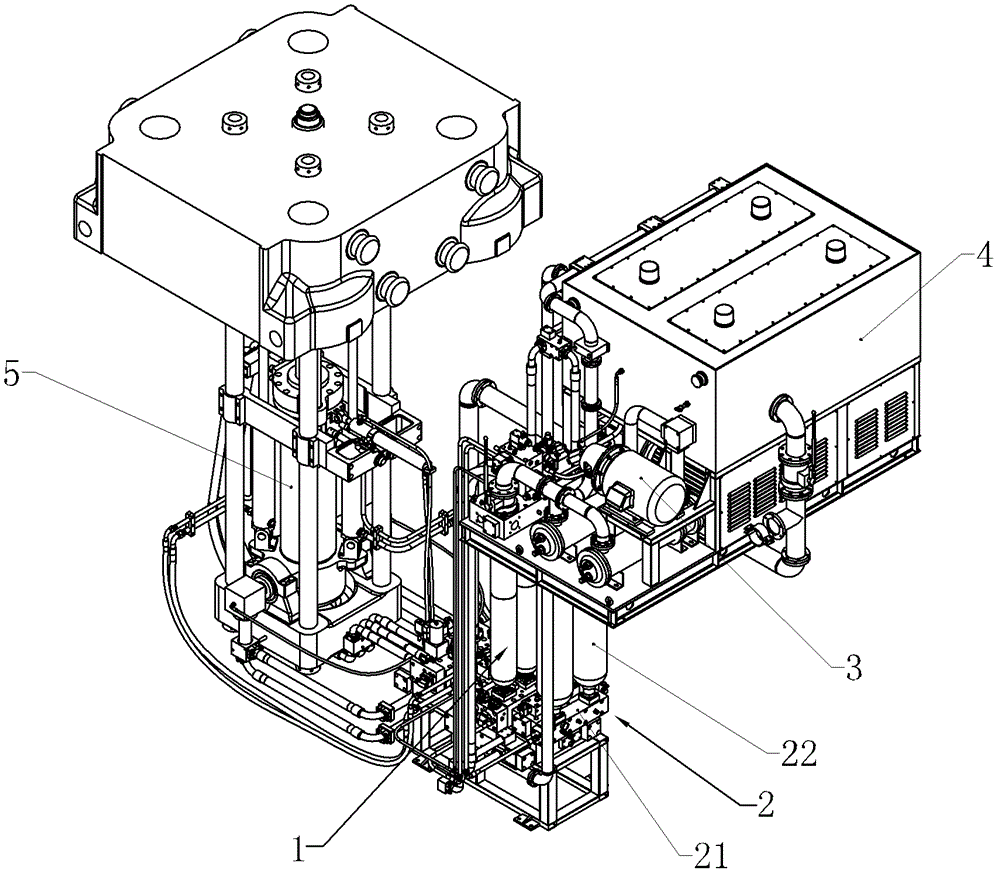

[0017] Such as figure 1 and figure 2 As shown, the hydraulic device described in this embodiment is used to drive the injection cylinder 5 of the inner cavity metal extrusion molding machine. composition. The input oil path of the small-flow high-pressure oil pump 3 is connected with the oil tank 4, and its output oil path is connected with the high-pressure accumulator group. The input oil circuit of the medium pressure accumulator group 2 is connected with the oil tank. The output oil passages of the high-pressure accumulator group 1 and the medium-pressure accumulator group 2 are both connected to the injection cylinder 5 .

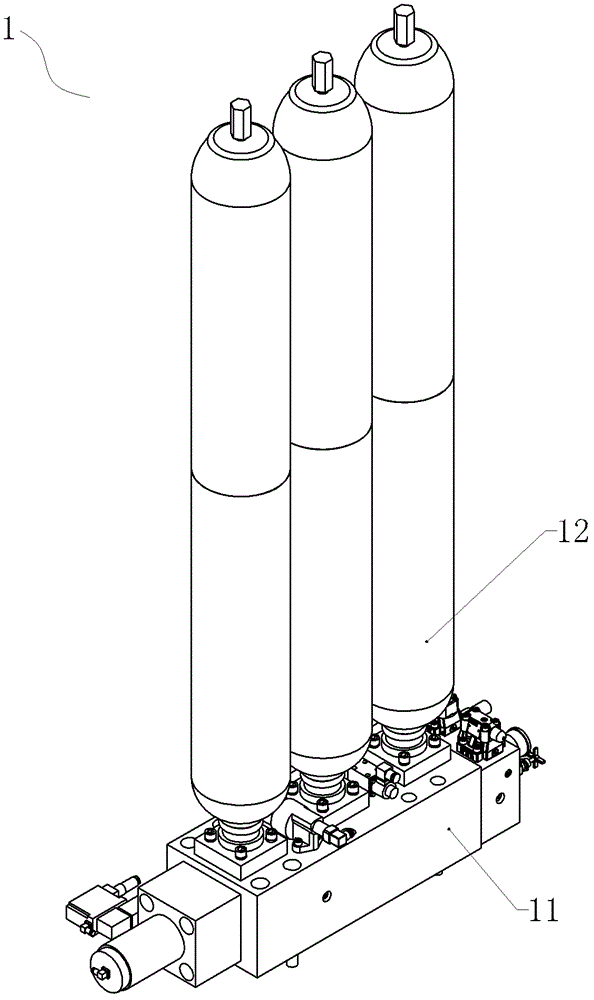

[0018] The high-pressure accumulator group 1 is mainly composed of a high-pressure oil circuit block assembly 11 and three high-pressure accumulators 12 . The high-pressure oil circuit block assembly is mainly composed of a high-pressure oil circuit block and several solenoid valves, and a pressure oil circuit is arranged in the high-pressure oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com