Direct drive type stroke control pressurizing type hydraulic machine of oil-less pump alternating current servo motor

A technology of AC servo motor and stroke control, which is applied in the driving device of stamping machine, forging press, press machine, etc., to achieve the effects of high positioning accuracy, flexible and adjustable working characteristics, and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

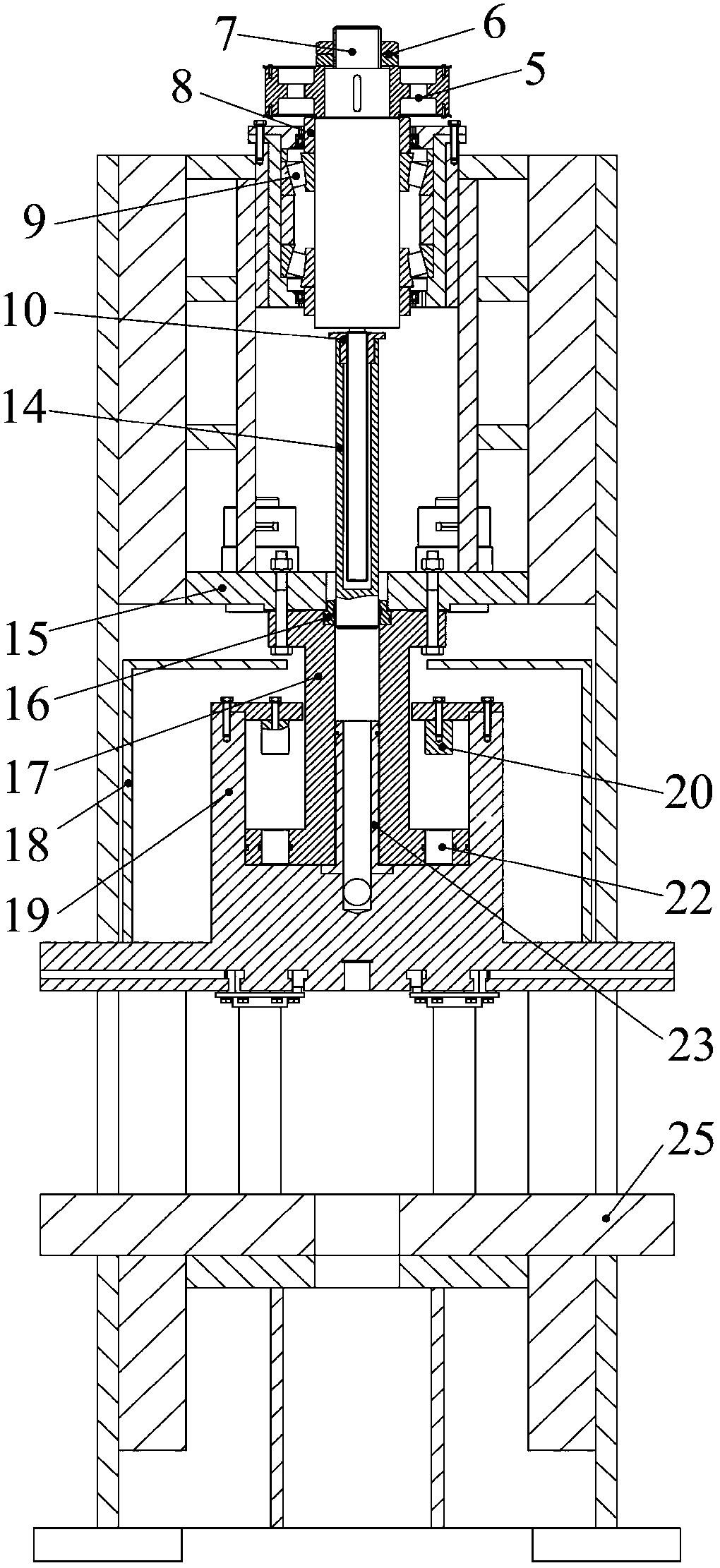

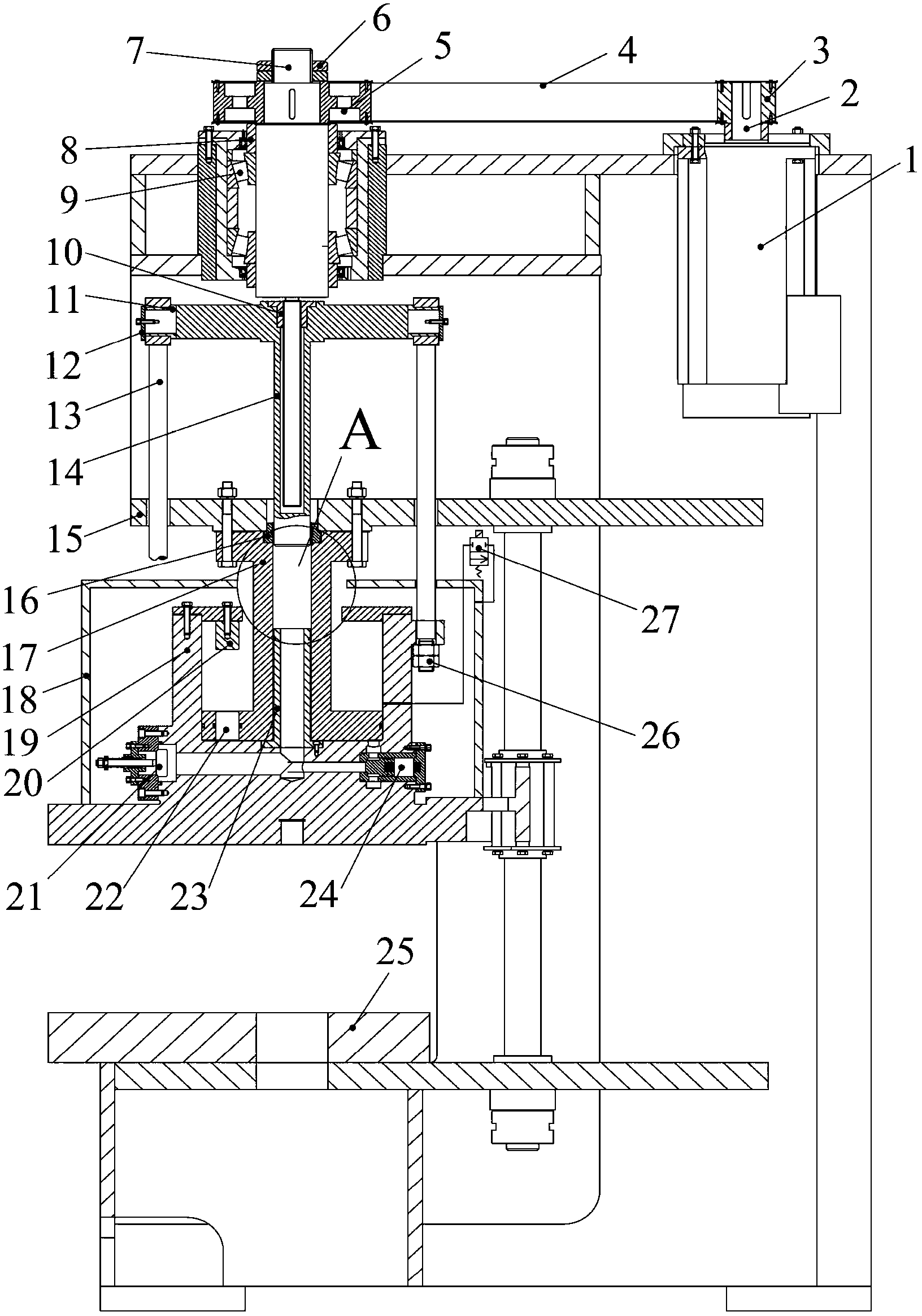

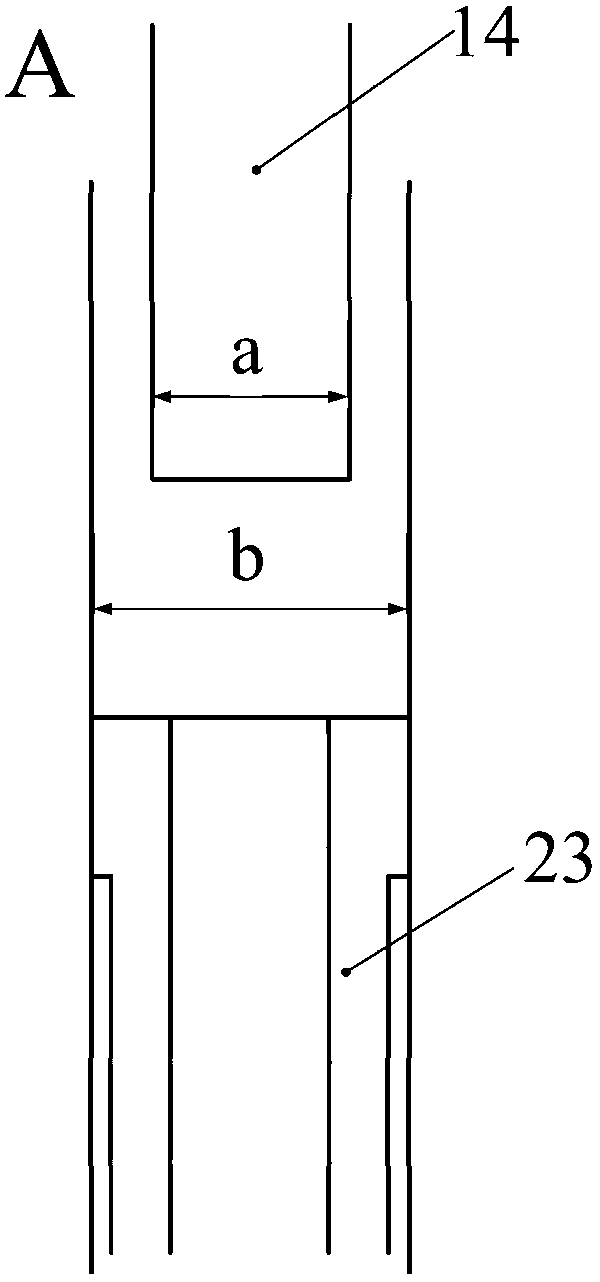

[0017] Such as Figures 1 to 2As shown, an oil-pump AC servo motor direct-drive stroke control pressurized hydraulic press includes an AC servo motor 1 and a small pulley 3 connected to its rotating shaft 2. The small pulley 3 is connected to a large belt through a toothed belt 4 The pulley 5 and the large pulley 5 are integrated with the ball screw 7 through two large round nuts 6. The large pulley 5 can drive the ball screw 7 to rotate together. The lower end of the large pulley 5 is supported on the bearing 9 through the support sleeve 8. The large pulley 5 is used as an inertia wheel, the ball screw 7 is equipped with a screw nut 10, the screw nut 10 and the large piston 14 are radially matched and connected as one, and the two ends of the large piston 14 are symmetrically connected with a pull rod 13, and the pull rod 13 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com