Electrolytic copper foil equipment fly cutter device

A technology of electrolytic copper foil and equipment, which is applied in the field of anode flying knife device of electrolytic copper foil equipment, can solve the problems of high processing cost, waste of energy, large volume, etc., and achieve the effects of convenient operation and maintenance, guaranteed continuity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

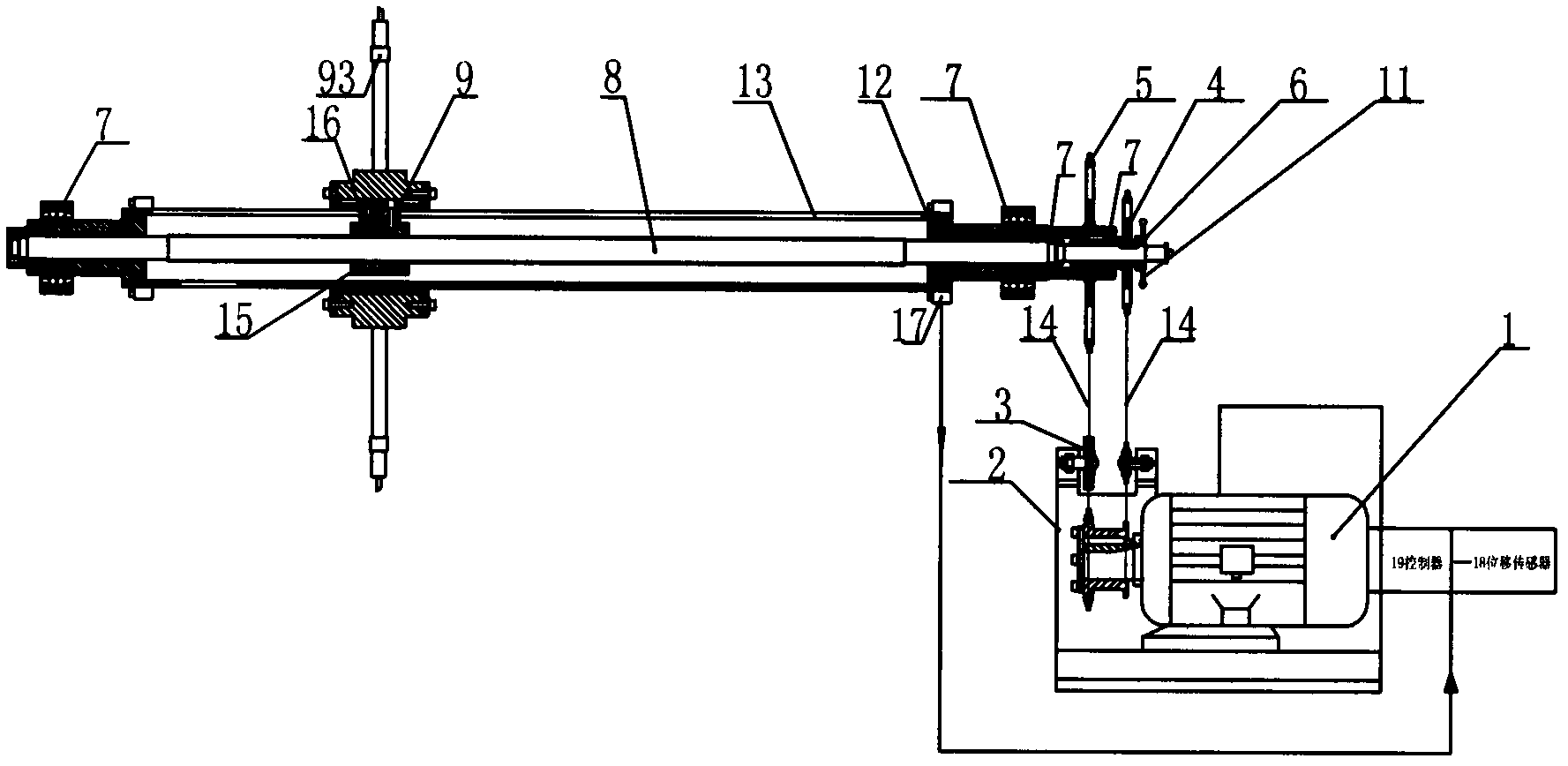

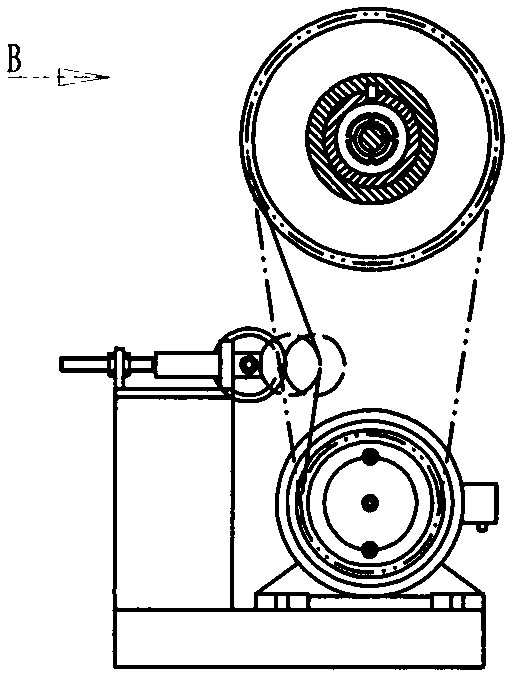

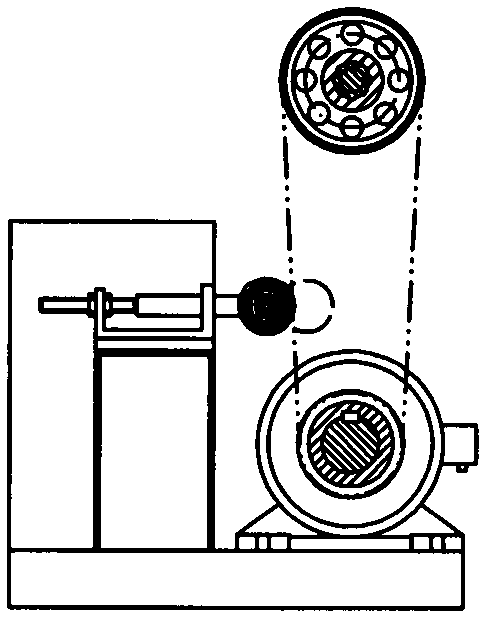

[0026] Such as figure 1 , figure 2 , image 3 Shown is a schematic structural diagram of the flying knife device of the electrolytic copper foil equipment of the present invention, including a power source, a transmission assembly and a knife bar assembly, the power source is a frequency conversion motor 1, and the main drive wheel 2 is arranged at the power output end of the frequency conversion motor 1; the transmission assembly It includes two main drive wheels 2, a feed sprocket 4, a rotating sprocket 5, a rotating cylinder 12, a rolling screw 8, and a rolling nut 15; the rotating cylinder 12 is a hollow long cylinder with a feed groove 13 arranged in the axial direction. The two ends are respectively supported by bearings; the rolling screw 8 is coaxially arranged in the rotating cylinder 12 and the two ends are respectively rotatably connected to the rotating cylinder 12 through the self-aligning bearing 7; the rolling nut 15 can rotate under the drive of the rolling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com