Rotating disc type automatic ceramic roll forming system

A roll forming system and roll forming machine technology, applied in the direction of pressing rollers, etc., can solve the problems of low degree of automation, low blanking efficiency, high labor intensity, etc., and achieve good product versatility, improved production efficiency, and improved operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

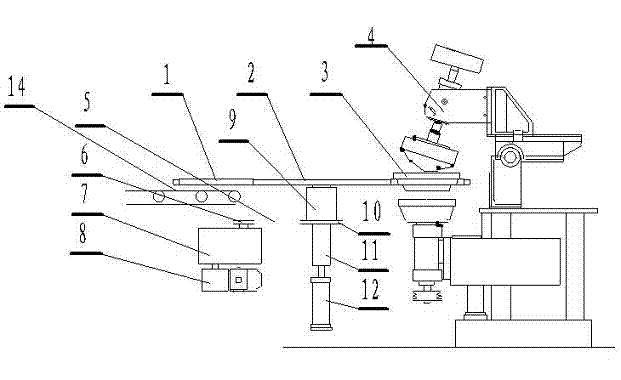

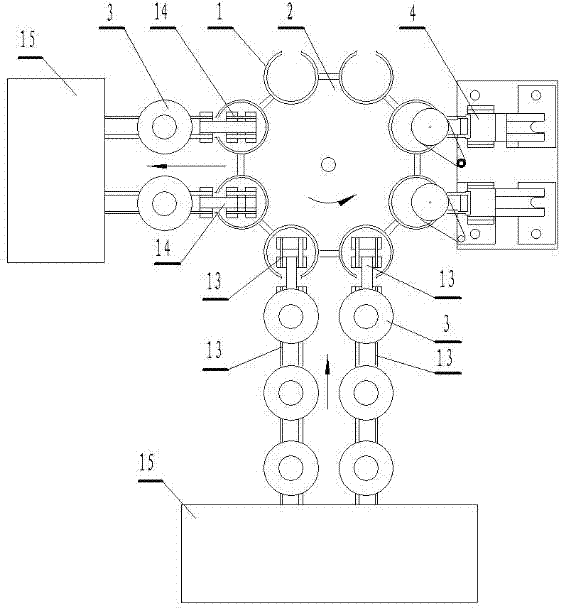

[0015] Such as figure 1 , 2 As shown, a turntable ceramic automatic roll forming system includes a roll forming machine 4, a turntable 2, a plaster mold 3, a drying oven 15, a turntable rotating device and a hydraulic control system. Wherein the roll forming machine 4 is set to double roll head rolling, the roll forming machine 4 is connected with the turntable 2, and the device adopts a double-row in-and-out mold conveyor belt, which can simultaneously roll form two products, the starting end of the mold conveyor belt 13 and the The end of the die conveyor belt 14 is connected by a transition belt, and the position of the transition belt is equipped with a dry box 15, and the feed conveyor belt 13 and the mold exit conveyor belt 14 are connected together in the dry box 15, and the rotary table 2 includes eight molds. Bracket 1, fixed sleeve 9, lifting guide rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com