High-efficacy multi-workspace automatic loading and unloading press machine set

A technology of automatic loading and unloading and working area, which is applied in the field of hydraulic panel presses, and can solve problems such as easy scattering and unbalanced production of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments.

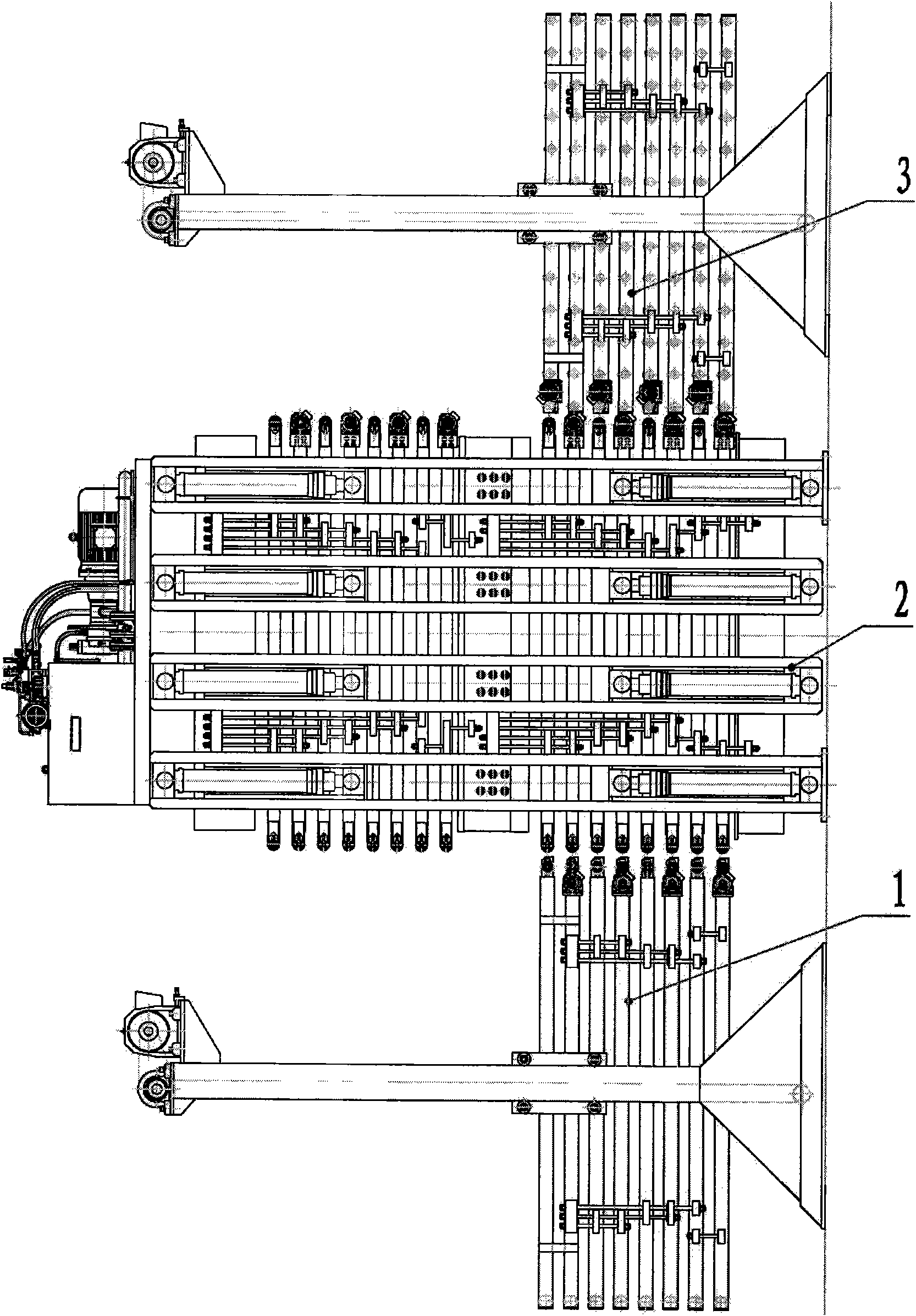

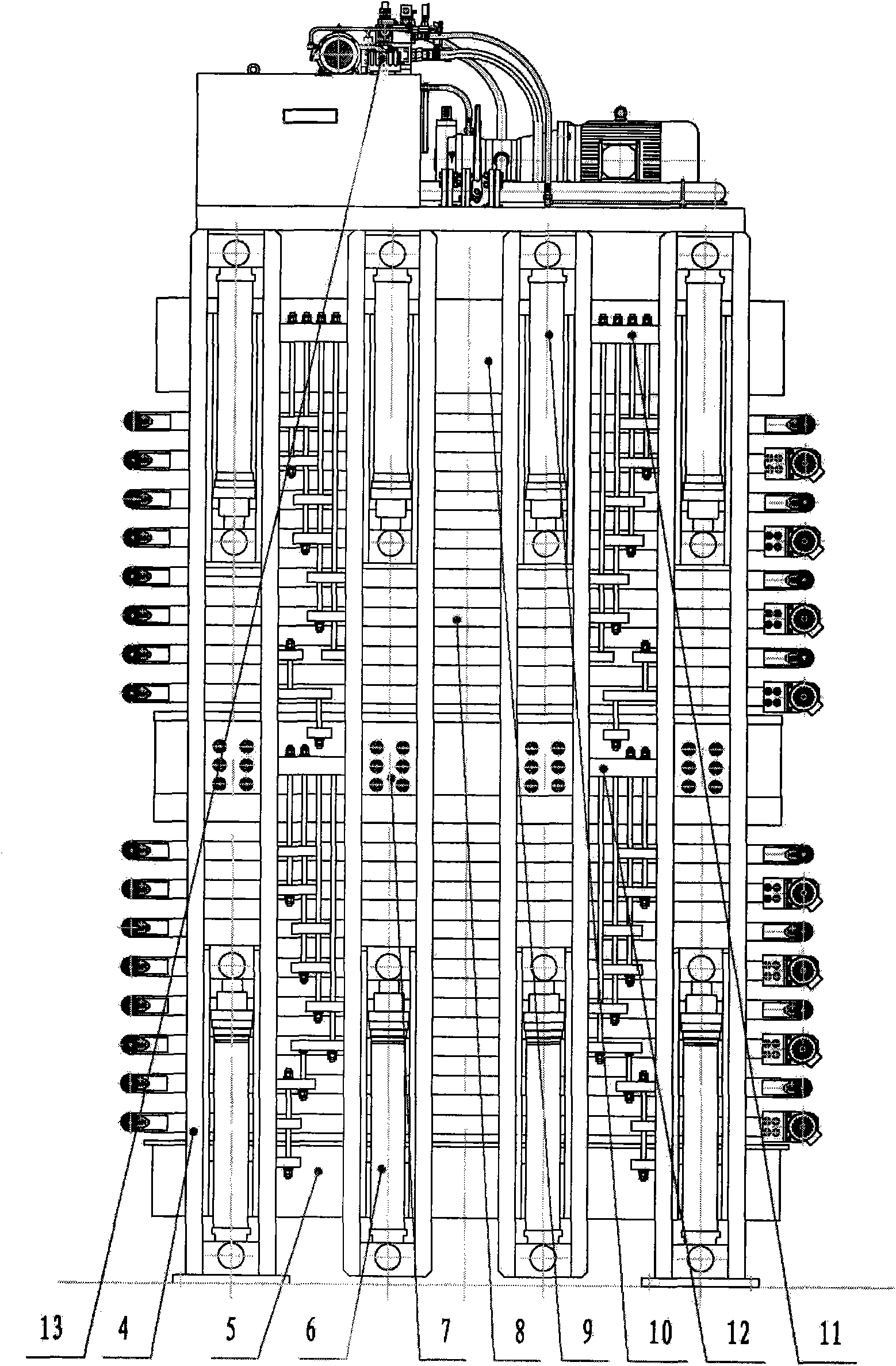

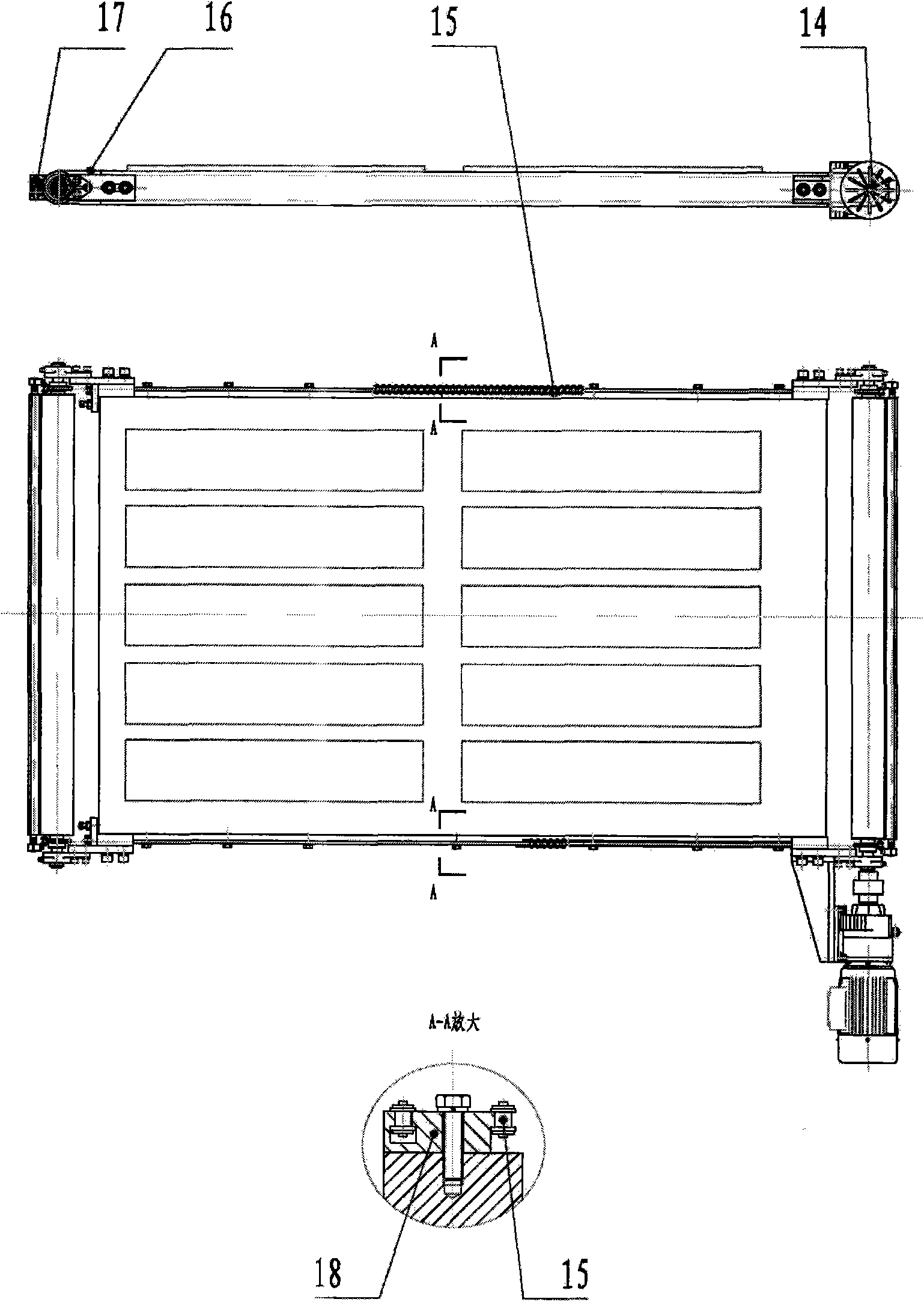

[0023] In the figure 1. Plate loading machine, 2. Press machine, 3. Plate unloading machine, 4. Press frame, 5. Lower movable workbench, 6. Lower work area cylinder, 7. Fixed workbench, 8. Belt conveyor mechanism Pressure plate, 9. upper movable table, 10. upper working area cylinder, 11. upper working area pressure plate hoisting limit device, 12. lower working area pressure plate hoisting limit device, 13. hydraulic system, 14. micro reduction Motor, 15. Synchronous drive chain, 16. Conveying film, 17. Rolling film device, 18. Synchronous chain guide, 19. Upper fixed seat, 20. Upper guide boom, 21. Upper movable hanger, 22. Nut, 23. Locking nut, 24. Spring, 25. Lower fixed seat, 26. Lower guide boom, 27. Lower movable hanger.

[0024] Such as figure 1 As shown, the high-efficiency double working area automatic loading and unloading press unit is composed of three par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com