Nifedipine controlled release tablet and preparation method thereof

A technology of nifedipine and tablet cores, applied in the field of nifedipine controlled-release tablets and its preparation, can solve problems such as hindering industrial production and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The present invention also provides a preparation method of nifedipine controlled-release tablets, comprising the following steps:

[0083] A) mixing 5-45% of nifedipine, 25%-85% of suspending agent, 1-25% of penetration enhancer and 0.5-10% of lubricant to obtain the drug-containing layer material;

[0084] Mixing 45-90% of permeation-enhancing polymer, 5-45% of permeation-enhancing agent, 0.1-4% of coloring agent and 0.1-10% of lubricant to obtain the booster layer material;

[0085] B) compressing the drug-containing layer material and the booster layer material in the step A) to obtain a double-layer tablet core;

[0086] C) Mix the film-forming material, the porogen and the solvent to obtain a coating solution, and use the coating solution to coat the double-layer tablet core obtained in the step B) to obtain a coated tablet. The film-forming The mass ratio of material and porogen is 100: (5-30);

[0087] D) perforating one side of the drug-containing layer of th...

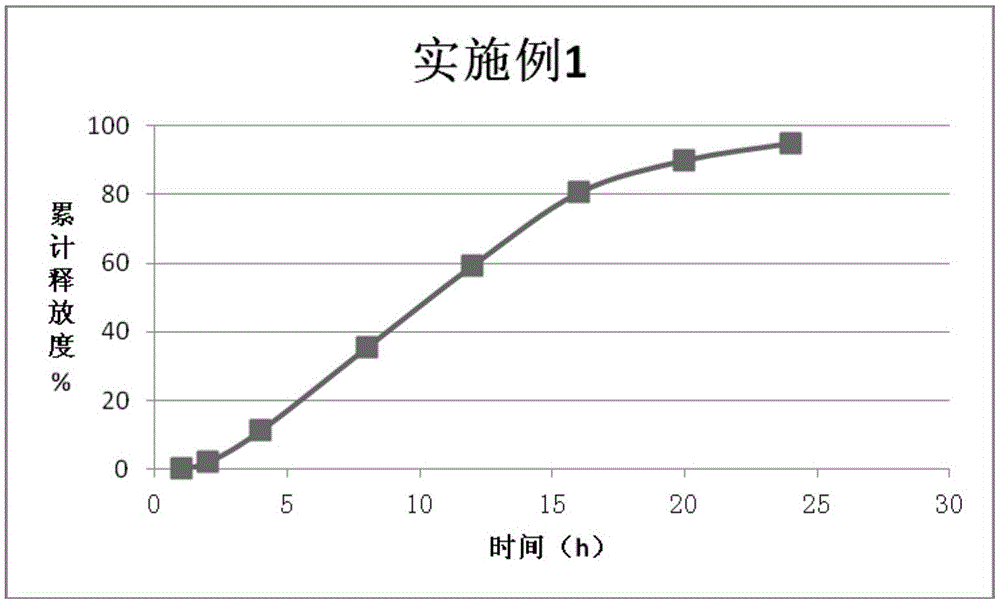

Embodiment 1

[0100] Drug-containing layer prescription (amount per tablet):

[0101]

[0102] Booster layer prescription (amount per tablet):

[0103]

[0104] Controlled release coat prescription (1000 tablets):

[0105]

[0106] Shading layer prescription (1000 tablets):

[0107] Opadry 85G689189g;

[0108] 200g of water.

[0109] According to the above formula, each component of the drug-containing layer and each component of the booster layer were mixed separately for 10 minutes without adding a lubricant, and then mixed separately for 3 minutes after adding a lubricant, and the uniformly mixed drug-containing layer and booster layer were taken. Push layer material, use 9.0mm shallow concave abrasive tool to press double-layer tablet, tablet core hardness is 4kg / mm 2 ;

[0110] The compressed double-layer tablet core is covered with a semi-permeable film, the solid content of the controlled-release coating coating solution is 5%, the tablet bed temperature is 20° C., and ...

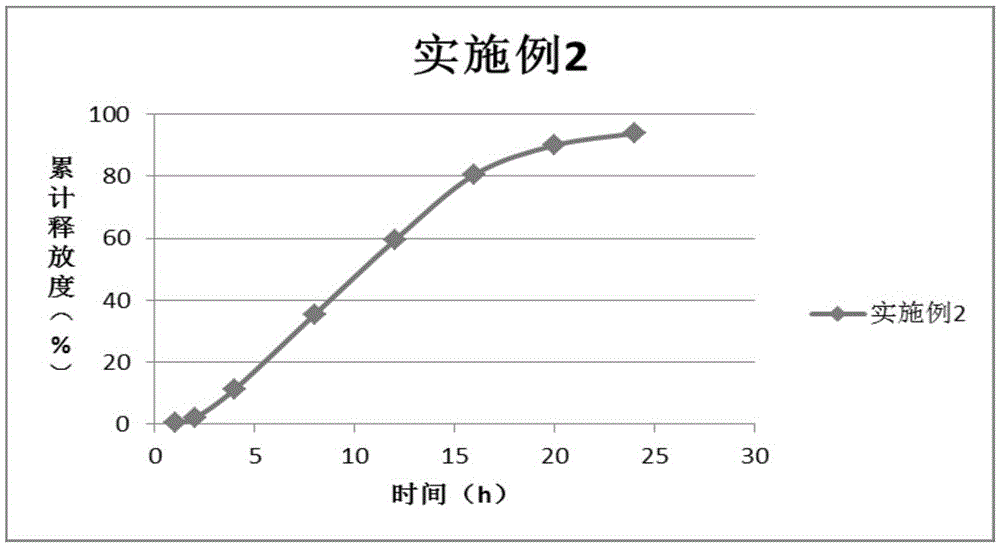

Embodiment 2

[0115] Drug-containing layer prescription (amount per tablet):

[0116]

[0117] Booster layer prescription (amount per tablet):

[0118]

[0119] Controlled release coat prescription (1000 tablets):

[0120] Opadry 19000430g;

[0121] Acetone 1000g;

[0122] 90g of water;

[0123] Shading layer prescription (1000 tablets):

[0124] Opadry 85G689188.5g;

[0125] 190g of water.

[0126] According to the above formula, the components of the drug-containing layer and the components of the booster layer were mixed for 15 minutes without adding lubricant, and then mixed for 5 minutes after adding lubricant, and the uniformly mixed drug-containing layer and booster layer were taken. Push layer material, use 9.0mm shallow concave abrasive tool to press double-layer tablet, tablet core hardness is 6kg / mm 2 ;

[0127] The compressed double-layer tablet core is coated with a semi-permeable film, the solid content of the coating solution of the controlled-release coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com