Concrete pipe pile automatic production line

An automatic production line and concrete pipe pile technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve problems such as not being able to meet market demand, high labor intensity of workers, exposure to dangerous sources, etc., to reduce manual hooking time , save hooking time, improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiment:

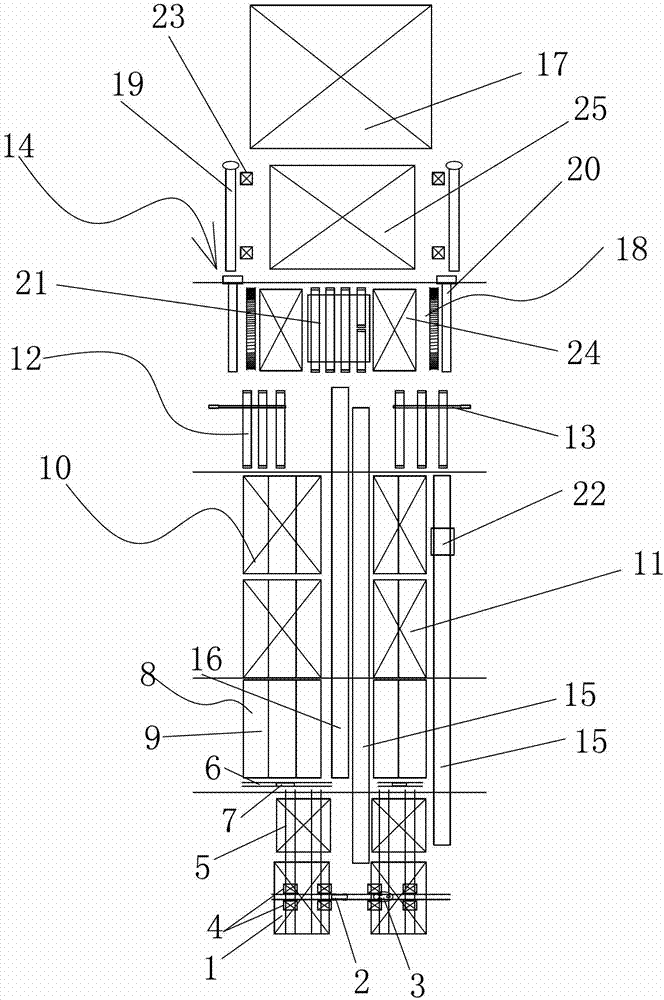

[0023] like figure 1 As shown, an automatic production line for concrete pipe piles includes a feeding area 1, in which a concrete mixer 2 and a distribution material capable of inputting the concrete in the concrete mixer 2 into the pipe mold are arranged in the feeding area 1 The car 3 is provided with a mold clamping area 5 behind the feeding area 1, and a crane capable of moving the pipe mold to the mold clamping area 5 is provided between the feeding area 1 and the mold clamping area 5. A stretching zone 6 is provided behind the clamping zone 5, and a stretching machine 7 capable of stretching the pipe mold after clamping is provided in the clamping zone 6. Behind the stretching zone 6, Be provided with centrifuge area 8, be provided with the centrifuge 9 that can carry out centrifugal treatment to described pipe mold in described centrifuge area 8, be provided with no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com