High-efficient anaerobic composting reactor

An anaerobic composting and reactor technology, applied in application, organic fertilizers, fertilization devices, etc., can solve the problems of reaction changes, inconvenient sampling and temperature measurement, and inability to reflect the anaerobic change process well, so as to ensure The effect of constant temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

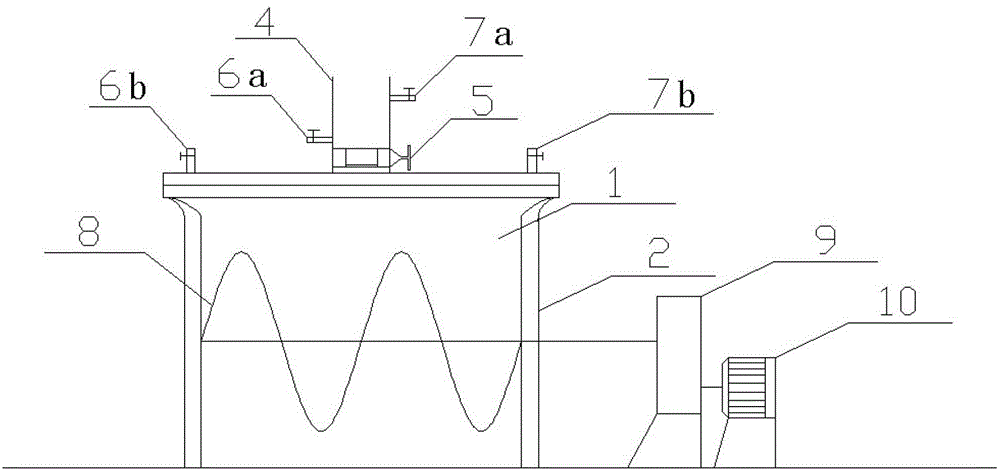

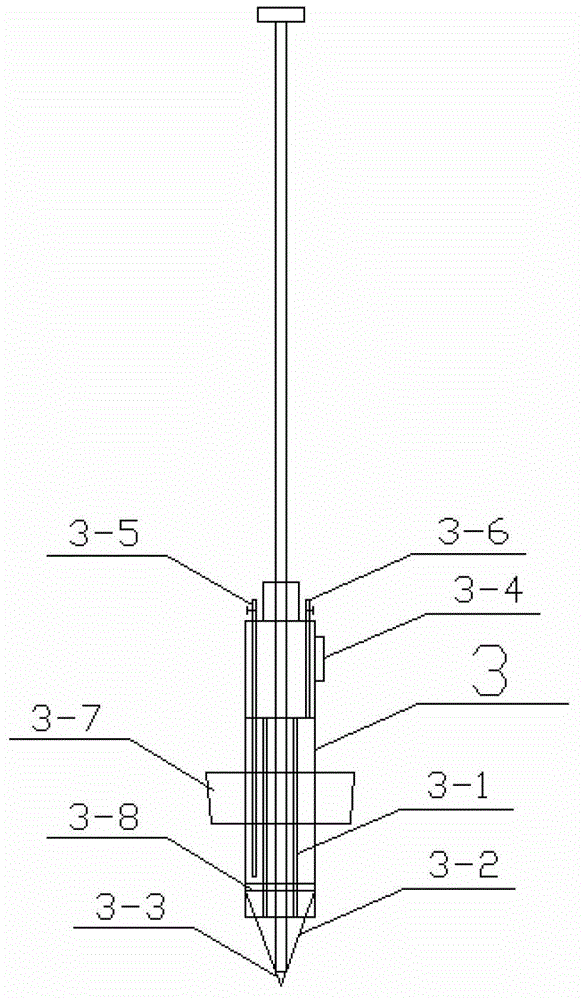

[0016] A high-efficiency anaerobic composting reactor, such as figure 1 As shown, it includes a reaction chamber system and a stirring system. The reaction chamber system includes a reaction chamber 1 and a sampler 3. The reaction chamber 1 is a sealed container provided with a water jacket 2. The reaction chamber 1 is a rectangular parallelepiped and is provided with a rectangular top cover for sealing. , the center of the top cover is provided with a sampling tube 4 and a rotary valve 5, the sampling tube 4 is respectively provided with an air inlet 6a and an air outlet 7a, and the two ends of the top cover are respectively provided with an air inlet 6b and an air outlet 7b, and the sampler 3 passes through The sampling tube 4 is inserted into the reaction chamber 1, and the sampler is as figure 2 As shown, it consists of ultraviolet lamp tube 3-1, sampling probe 3-2, temperature sensor 3-3, display 3-4, air inlet 3-5, exhaust port 3-6, rubber sleeve 3-7 and rubber gasket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com