Ultraviolet-curable and moisture-curable adhesive composition

一种粘合剂、组合物的技术,应用在聚醚粘合剂、粘合剂类型、非高分子有机化合物粘合剂等方向,能够解决无法有效地达到、可紫外固化粘合剂不能满足实际生产应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Method for preparing adhesive composition

[0055] The adhesive composition of the present invention can be prepared by putting materials into a stirring tank according to the ratio of raw materials of each adhesive composition as described above, and stirring according to a certain speed and time. The preparation process is generally carried out at normal temperature and pressure, and requires protection from light and constant temperature. Taking the following example 1 as an example, in the first step, the raw materials (meth)acrylate oligomer CN8004, isobornyl (meth)acrylate, and lauryl (meth)acrylate are sampled and weighed and put into the kettle For pre-stirring, the stirring speed is set at about 50 to about 80 rpm, and the stirring time is about 60 minutes; in the second step, GENIOSIL STP-E10 is sampled and weighed and put into the kettle for pre-stirring, and the stirring speed is set at about 100 to about 120rpm, stirring time is about 20min. The third s...

preparation example

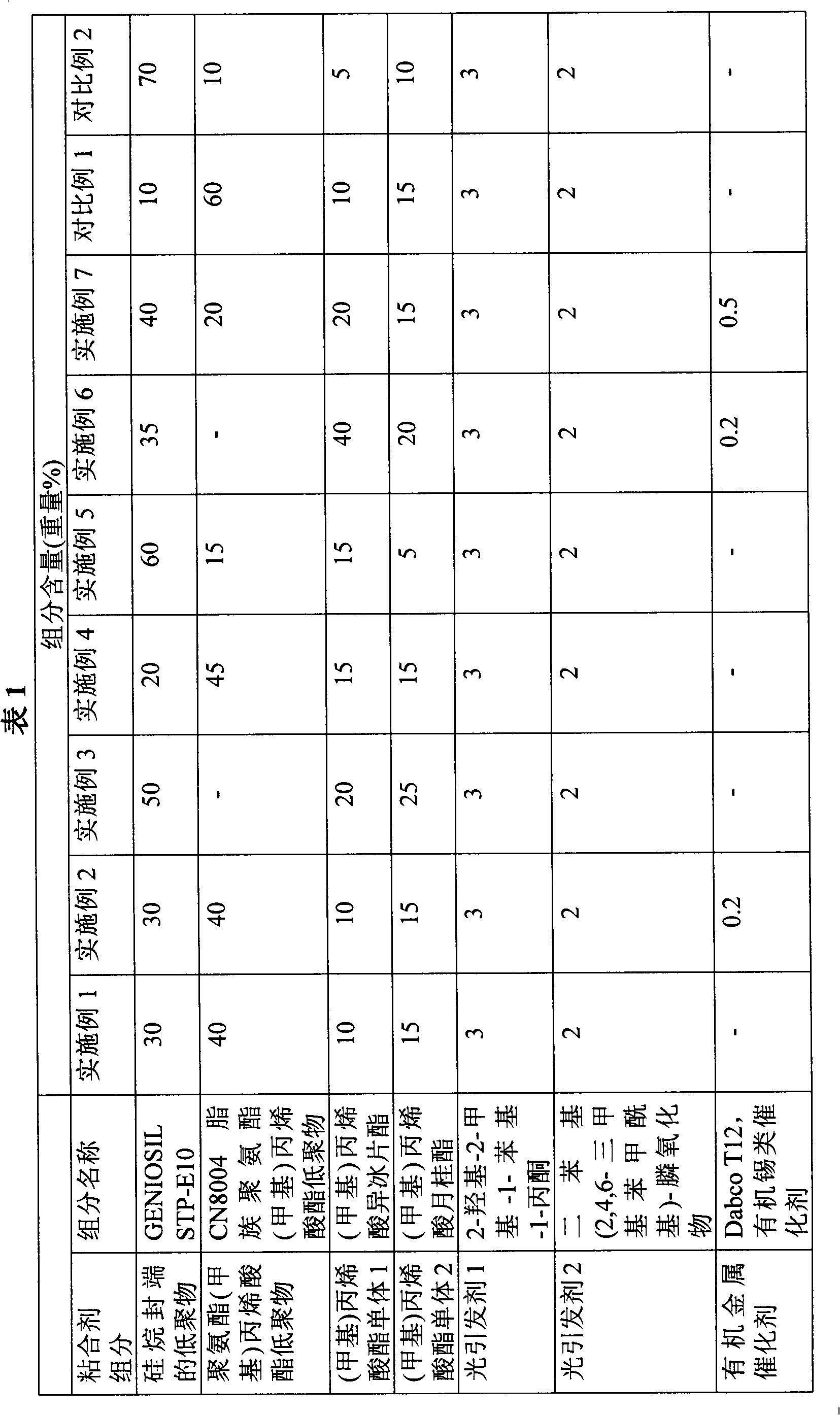

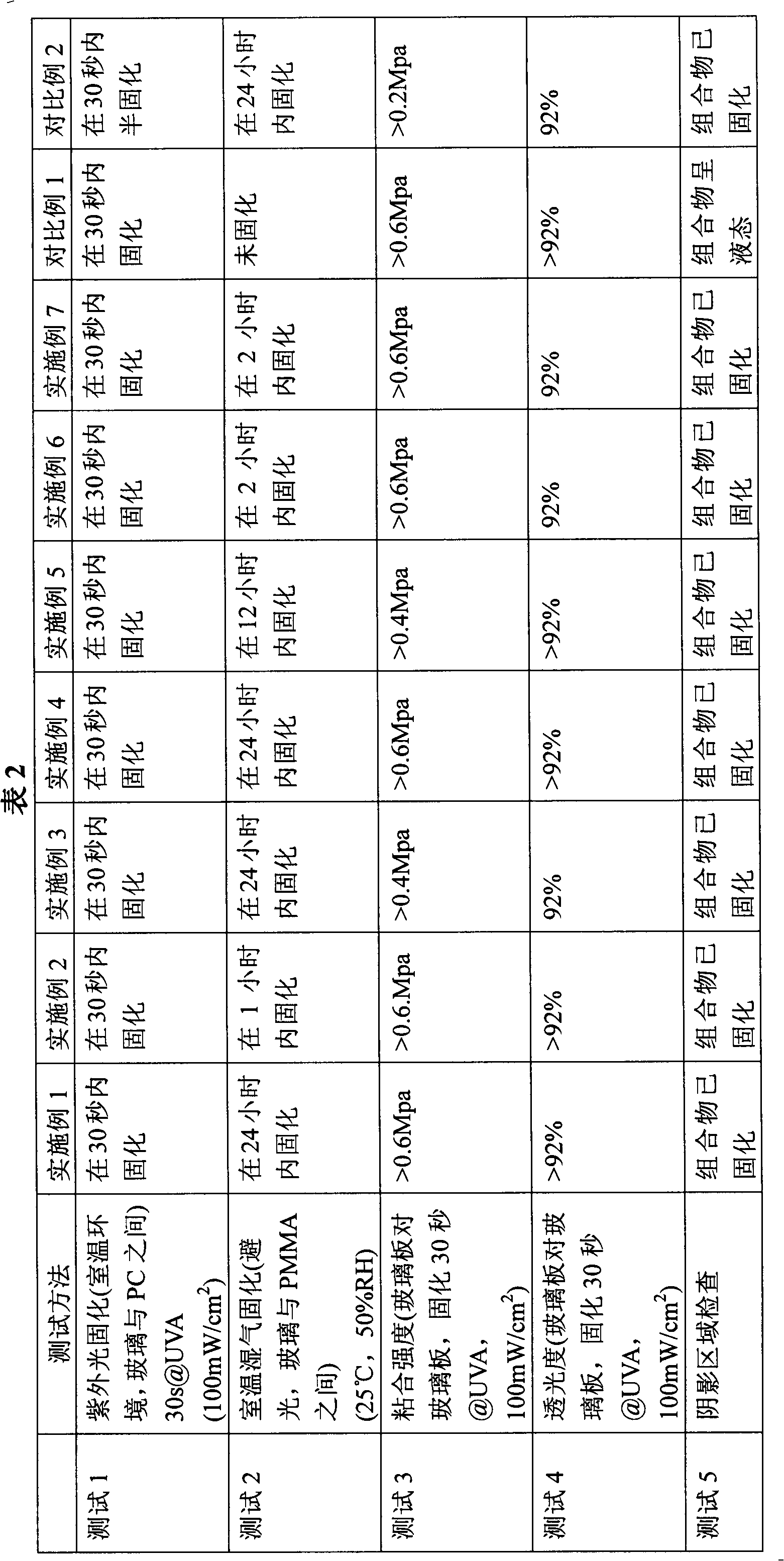

[0066]The adhesive composition of the present invention is prepared according to the preparation method described above. Table 1 lists the name and content of each component.

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com