Composite lamella

A composite sheet, composite film technology, applied in the direction of film/sheet adhesive, non-polymer organic compound adhesive, adhesive, etc., can solve the thickness limit, affect the response speed of mobile phone touch screen, affect users Problems such as the agility of human-machine interface use, to achieve the effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

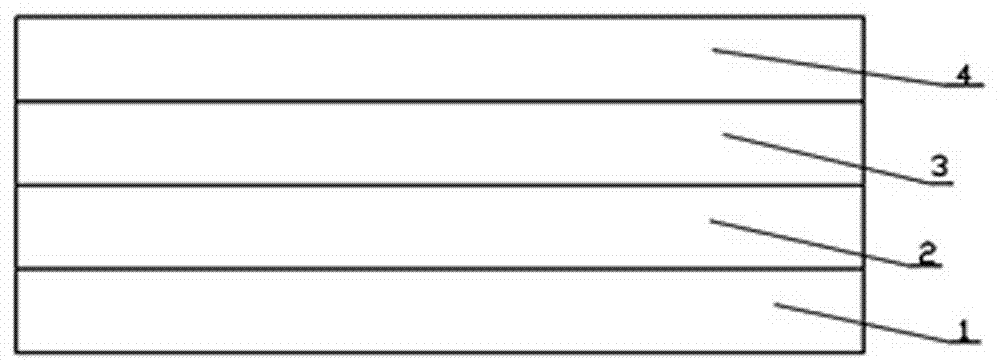

[0023] See attached figure 1 As shown, the composite sheet of the present invention includes more than one coating layer, and is characterized in that it includes:

[0024] Adhesive layer 1 for sticking to the adherend;

[0025] A composite film layer arranged on the upper end surface of the adhesive layer for barrier;

[0026] An antistatic layer 3 arranged on the upper end surface of the composite film for preventing electrostatic interference;

[0027] An anti-scratch layer 4 is provided on the upper end surface of the anti-static layer 3 for preventing scratches.

[0028] As a preferred embodiment, the composite film layer is a polyester film 2 . Because in the prior art, polyester film is colorless and transparent, has good mechanical properties, relatively high rigidity, toughness and hardness, and is resistant to friction, puncture and good barrier performance, and has been widely used.

[0029] As a preferred version, the colloid of the adhesive layer 2 comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com