Full-automatic squeezing method of camellia oil

A fully automatic, camellia oil technology, applied in the direction of oil/fat production, fat production, etc., can solve the problems of slow industrialization of Camellia oleifera, long return cycle, low yield per mu, etc., to reduce nutritional damage, improve work efficiency and effect , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

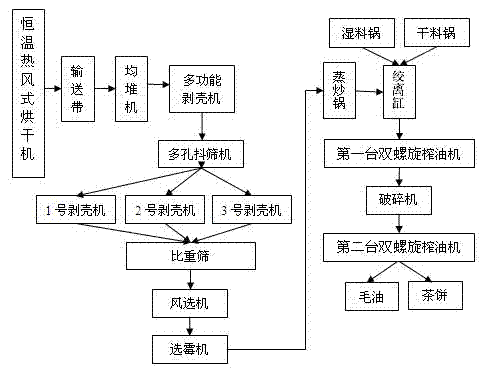

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the present embodiment provides a kind of camellia oil full-automatic pressing method, comprising:

[0021] a, drying: use the constant temperature hot air dryer to dry the camellia seeds, the temperature of the constant temperature hot air dryer is set to 60C °, when the temperature is reduced by 58C °, the blower of the constant temperature hot air dryer blows wind, when the temperature reaches 60C °, the blower stops blasting, so that the furnace temperature of the constant temperature hot air dryer remains between 58C °-60C ° and the camellia seeds are dried;

[0022] b. Heaping: transport the dried camellia seeds to the heaping machine for heaping, and after heaping, transport them to the multifunctional sheller for shelling;

[0023] c. Shelling: the camellia seeds after shelling by a multi-functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com