A semi-automatic threading machine

A looping machine and semi-automatic technology, which is applied to the looping machine connecting knitted fabrics, sewing machine components, sewing machine control devices, etc., can solve the problems of workers' high vision requirements, error-proneness, and increased worker burden, etc., and meet the vision requirements Not high, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

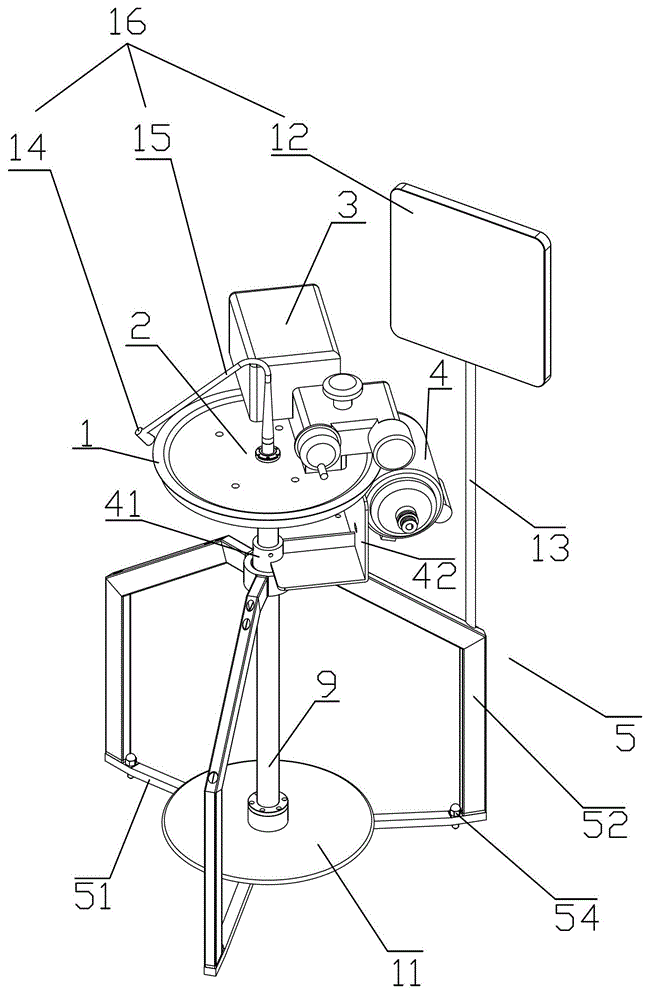

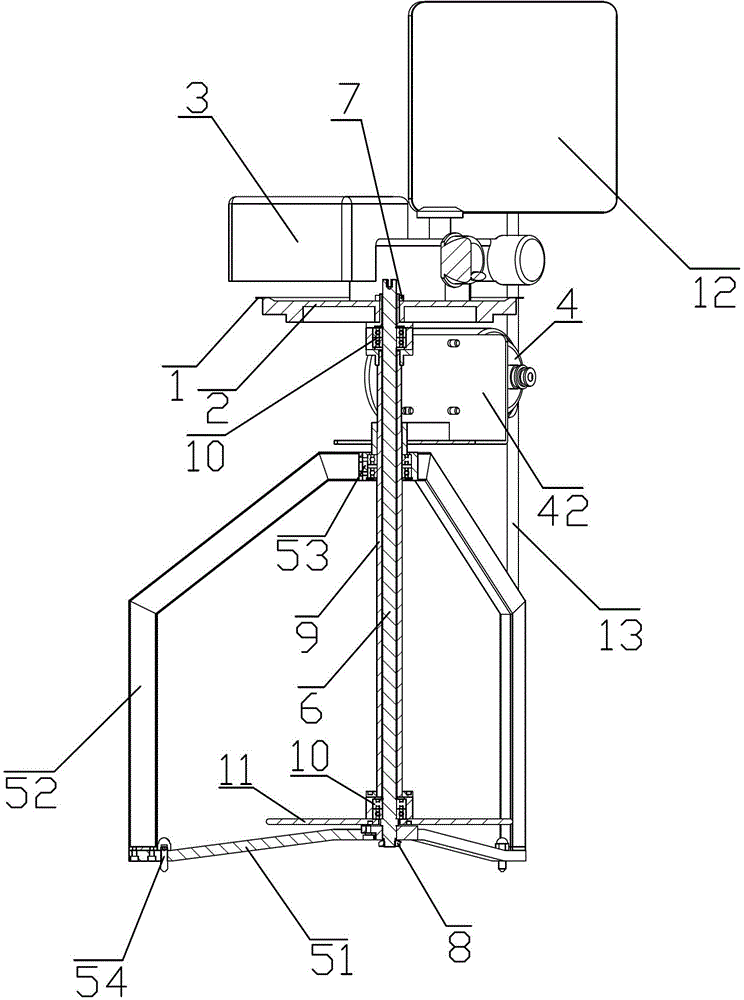

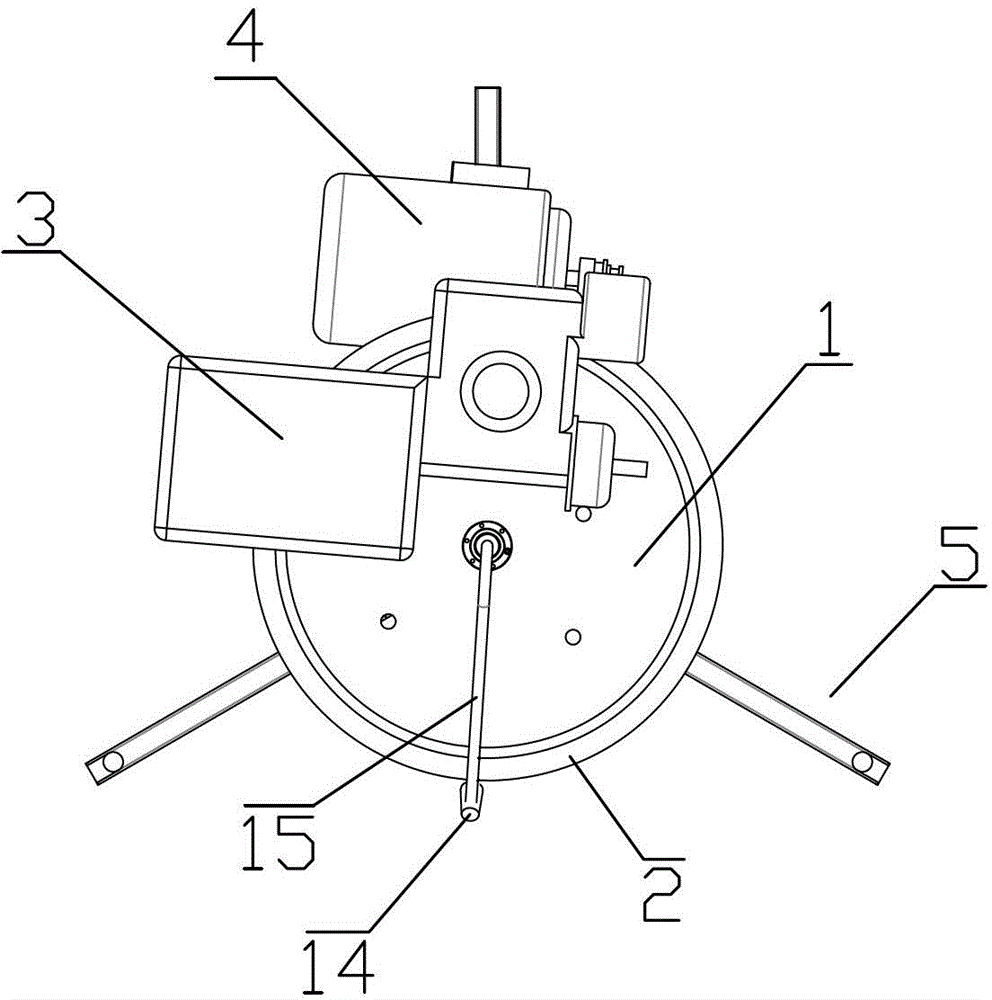

[0018] Such as figure 1 , 2 3. What the present invention discloses as shown in 3 is a kind of semi-automatic threading machine, and it comprises dial 1, and is fixed on the dial 1 and is arranged on the machine head 3 that is connected with ring gear 2 on the peripheral edge of dial 1, and this machine head 3 Driven by the main motor 4, the dial 1 is movably connected with the ring gear 2; it also includes a tripod support frame 5 and a fixed shaft 6 that is movably connected to the tripod support frame 5 in the axial direction, and one end of the fixed shaft 6 passes through a lock nut 7 It is fixedly connected to the lower end surface of the dial 1, and the other end is fixedly connected to the upper end surface of the rotating disk 11 through a fixed nut 8. The fixed shaft 6 is wrapped with a transition shaft 9, and the transition shaft 9 is fixed through the fixed shaft 9 at both ends of the fixed shaft 6. The bearing 10 limits the fixed shaft 6 in the transition shaft 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com