Partial steel web single-box four-chamber composite box girder suitable for low-tower cable-stayed bridges

A low-tower cable-stayed bridge, single box four-chamber technology, applied in bridges, buildings and other directions, can solve problems such as adverse effects on the overall structure, complex construction, long processing time, etc., to weaken the self-weight load effect, improve prestressing efficiency, The effect of speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes in detail the part of the steel web single-box four-chamber combined box girder suitable for the low-tower cable-stayed bridge of the present invention in combination with the drawings and specific embodiments. Components that are the same as those in the prior art use the same reference numerals, and detailed descriptions thereof are omitted.

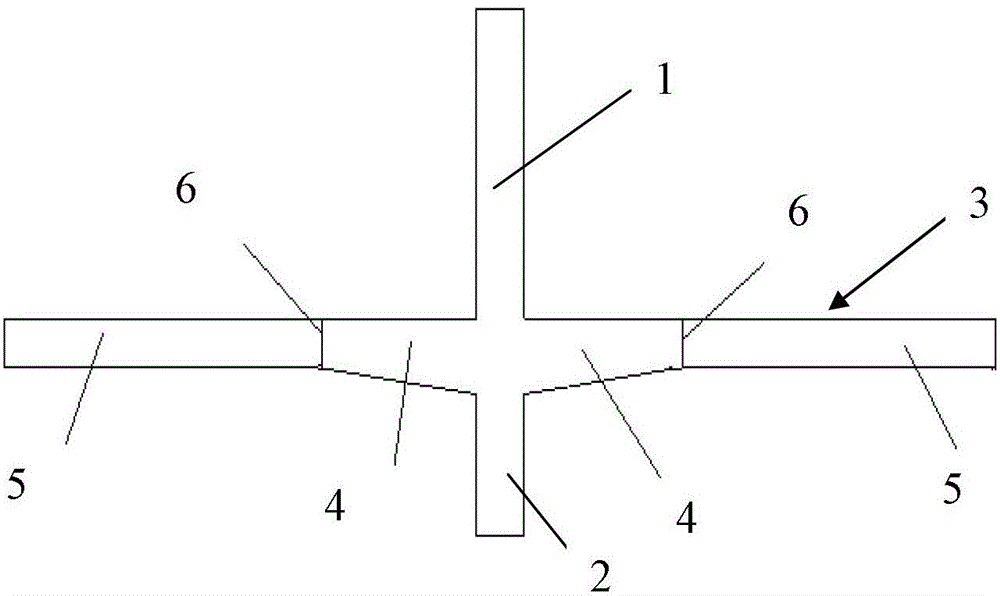

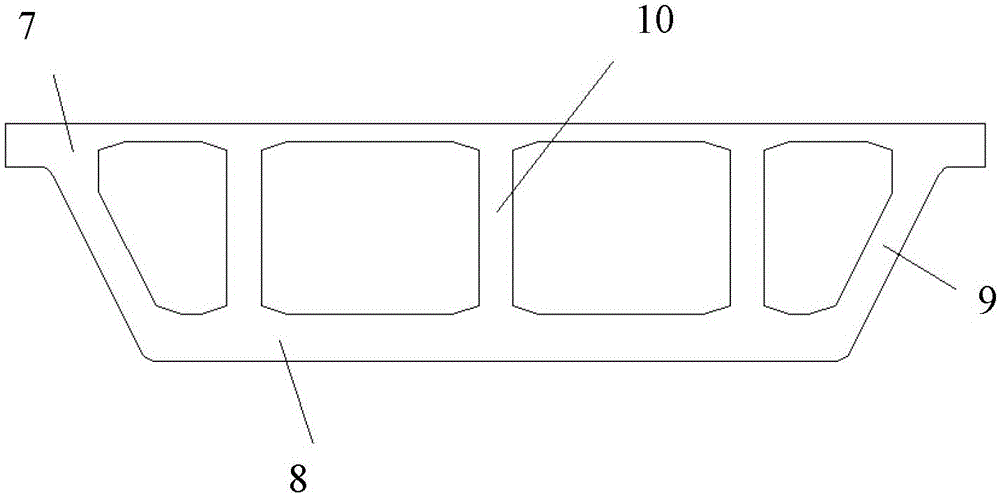

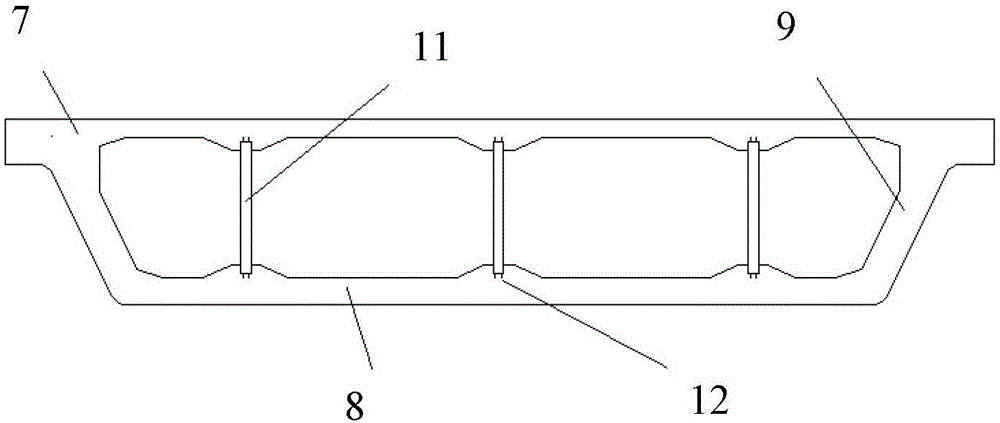

[0012] Such as image 3 and figure 1 , figure 2 As shown, the present invention provides a partial steel web single-box four-chamber composite box girder suitable for the equal height section of a low-tower cable-stayed bridge including a prestressed concrete top plate 7, a prestressed concrete bottom plate 8, and two prestressed concrete inclined webs 9 and three middle webs 11; wherein the prestressed concrete top plate 7 and the prestressed concrete bottom plate 8 are horizontally arranged on the upper and lower parts, and the two prestressed concrete inclined webs 9 are connected to the prestressed conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com