Cascade structure of submerged pump for ship and stowage motor

A technology of submersible pumps and electric unions, which is applied to parts, pumps, and pump devices of elastic fluid pumping devices, and can solve problems such as high cost of replacement parts, heavy maintenance workload, and poor application effects. Save maintenance time, reduce replacement costs, and facilitate disassembly or installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to accompanying drawing.

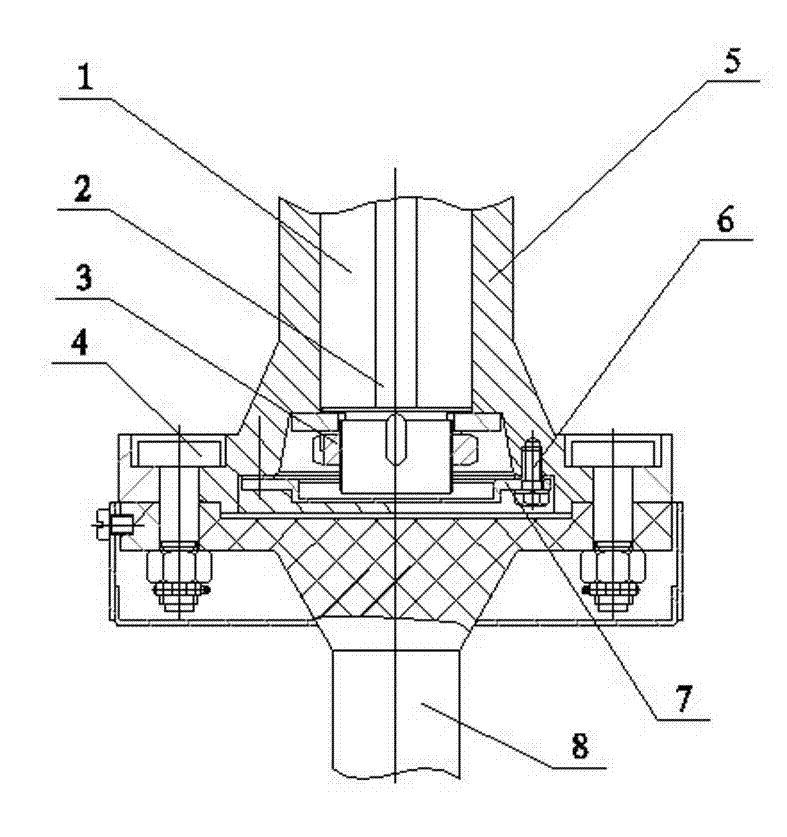

[0014] figure 1 The joint structure of the marine submersible pump and the loading motor is shown, which includes the motor shaft 1, the flat key 2, the round nut 3, the column pin 4, and also includes the coaxial electric coupling 5 and the pump coupling 8. Connect the electric coupling 5 and the pump coupling 8 through the column pin 4 to form a joint structure. figure 1 The component shown above is the electric coupling 5, which is a bushing with a flange at one end, and the outward end of the flange is provided with a convex stop and a concave shoulder hole. The convex spigot is a circular spigot, and its center is coaxial with the 5-axis hole of the electrical coupling. The outer convex seam is used as the positioning reference of the inner concave seam of the matching pump coupling 8. This structure is simple, the positioning is accurate, it is easy to disassemble or insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com