Column type elastic body

An elastomer and column technology, applied in weighing equipment using elastically deformable parts, detailed information of weighing equipment, instruments, etc., can solve the problems of complex overload protection structure, complex processing, troublesome installation, etc. The effect of small deformation, improved process performance and excellent torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

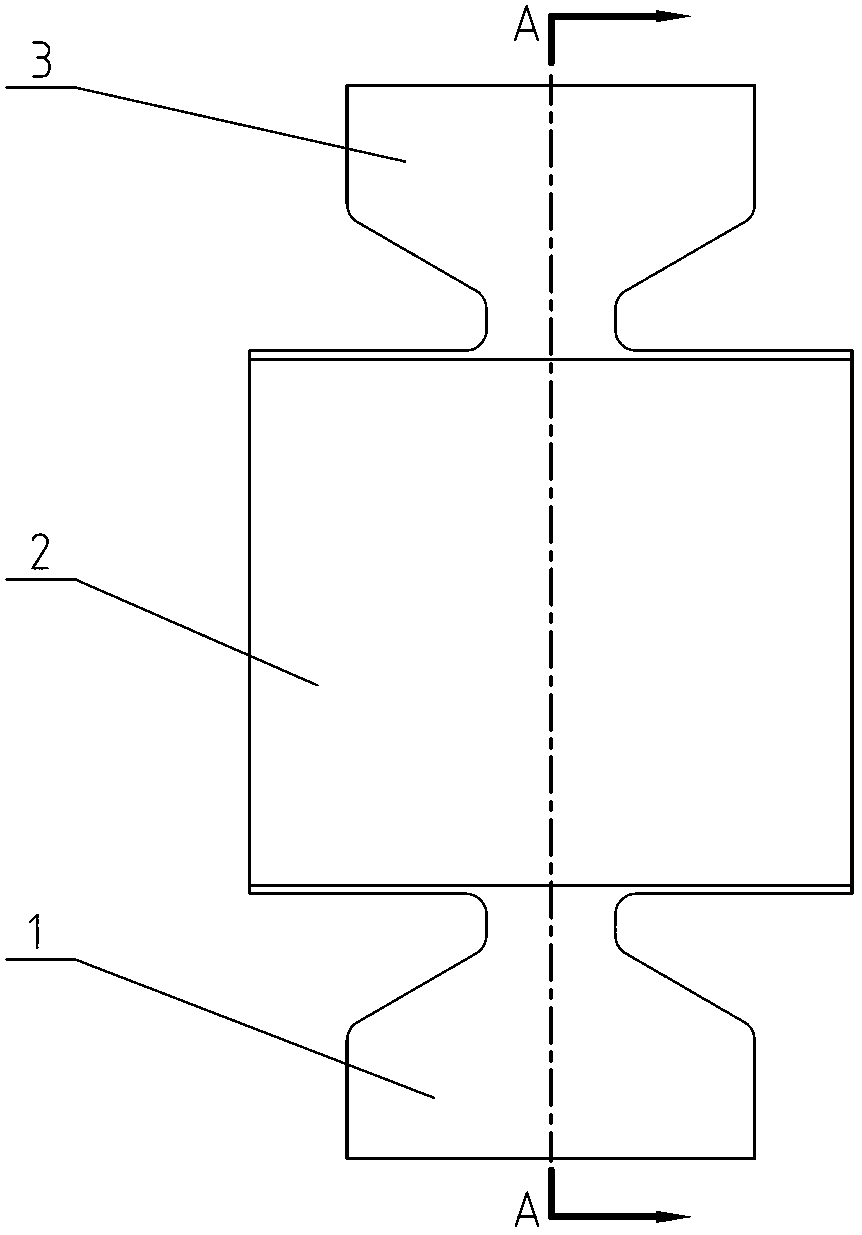

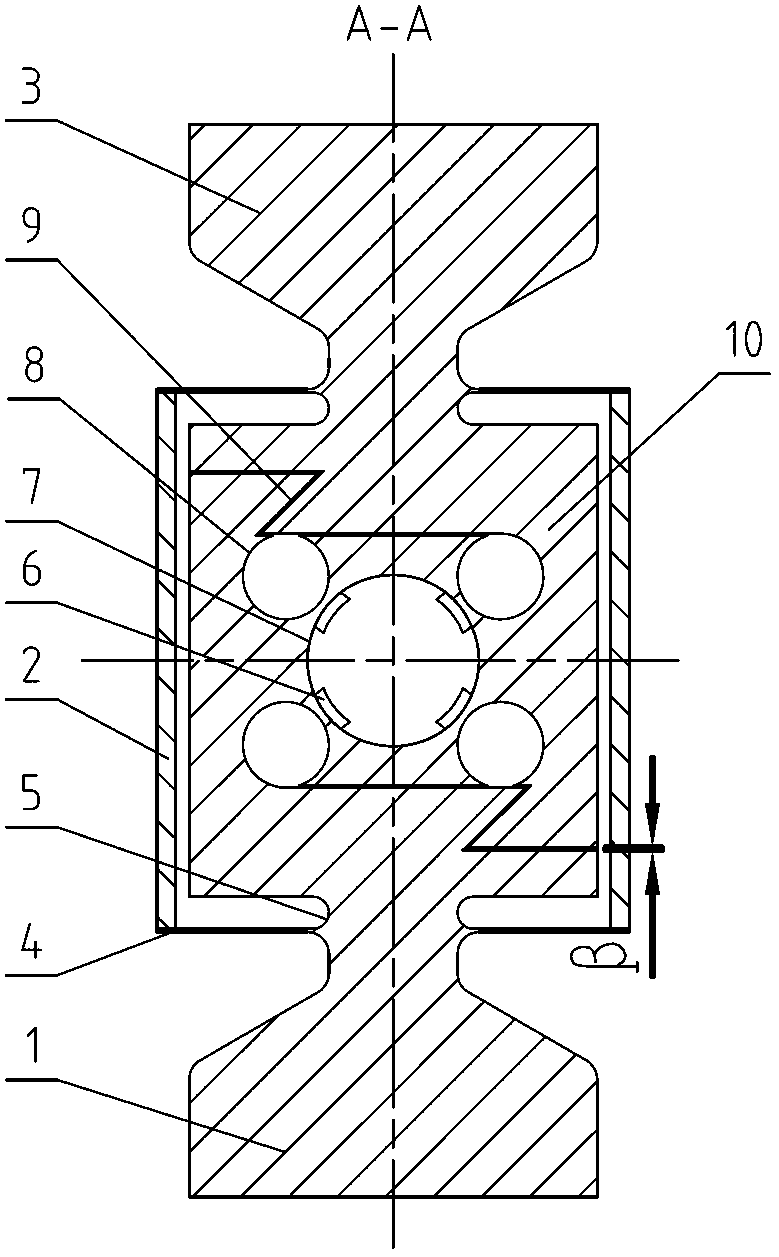

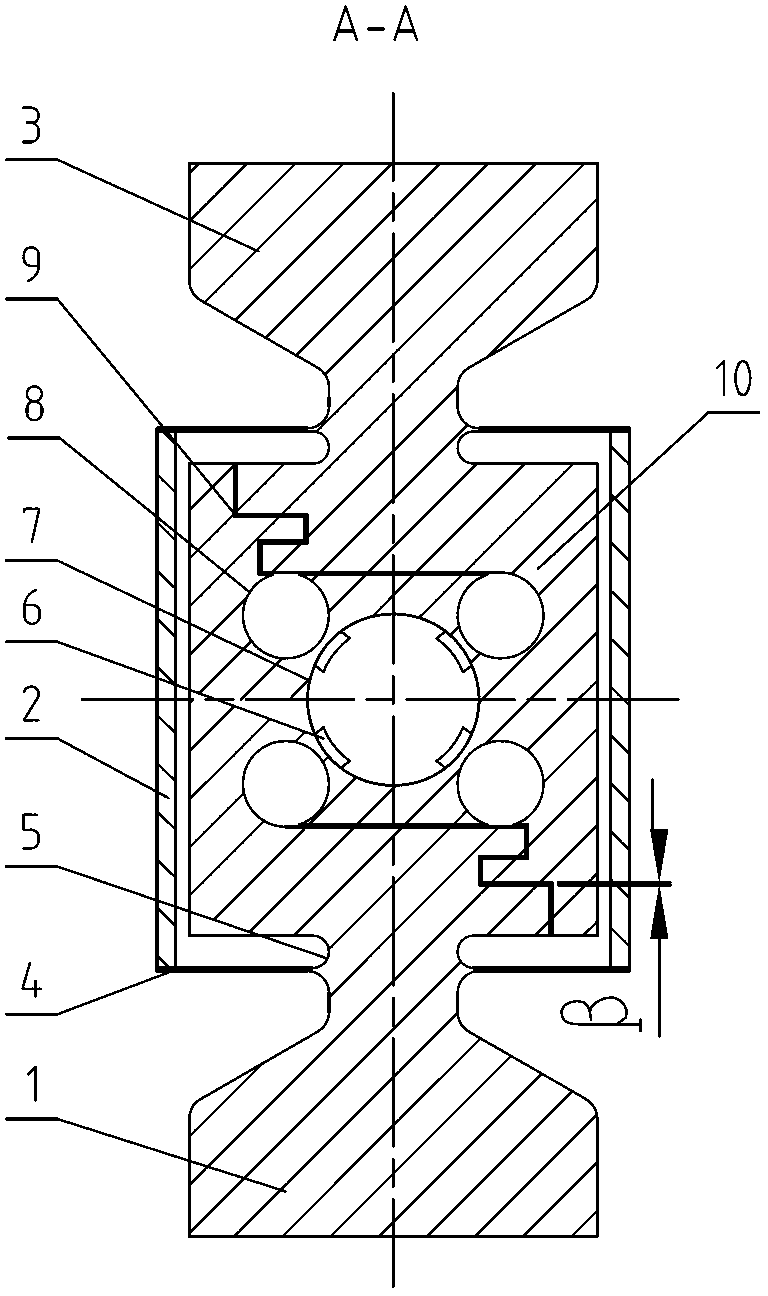

[0019] See Figure 1-3 As shown, the cylindrical elastic body of the present invention includes a fixed part 1 arranged on both sides of the elastic body, a load-bearing part 3 and a strain part 10 arranged between the fixed part 1 and the loaded part 3, and the elastic body is provided with a shaft diameter The elastic body is divided into a fixed part 1, a strain part 10 and a bearing part 3. The fixed part 1 can fix the elastic body on the base through a fastener, and the bearing part 3 is connected with the bearing part through a fastener. The strain part 10 of the present invention comprises two ring grooves 5 arranged on the elastic body, a strain hole 7 arranged between the two ring grooves 5 and a strain gauge 6 fixed in the strain hole 7, the strain hole 7 and the deformation hole 8 Correspondingly, the ring groove 5 of the present invention can adopt a U-shaped ring groove, the strain gauge 6 is fixed at the thin wall 4 corresponding to the strain hole 7 and the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com