Non-contact LED junction temperature measurement method and device

A test method, non-contact technology, applied in measuring devices, thermometers, measuring heat, etc., can solve problems such as high cost, inability to be widely used, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

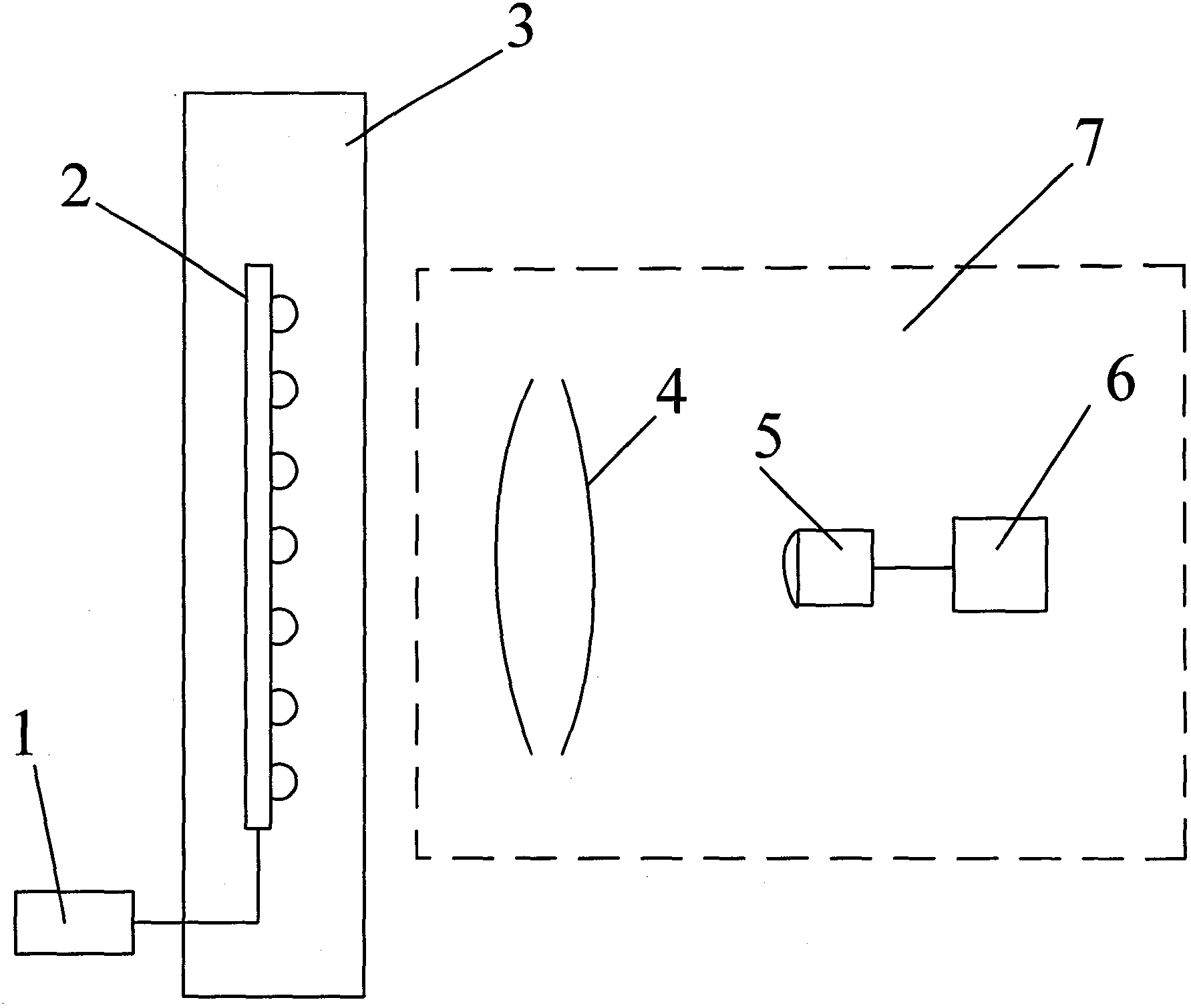

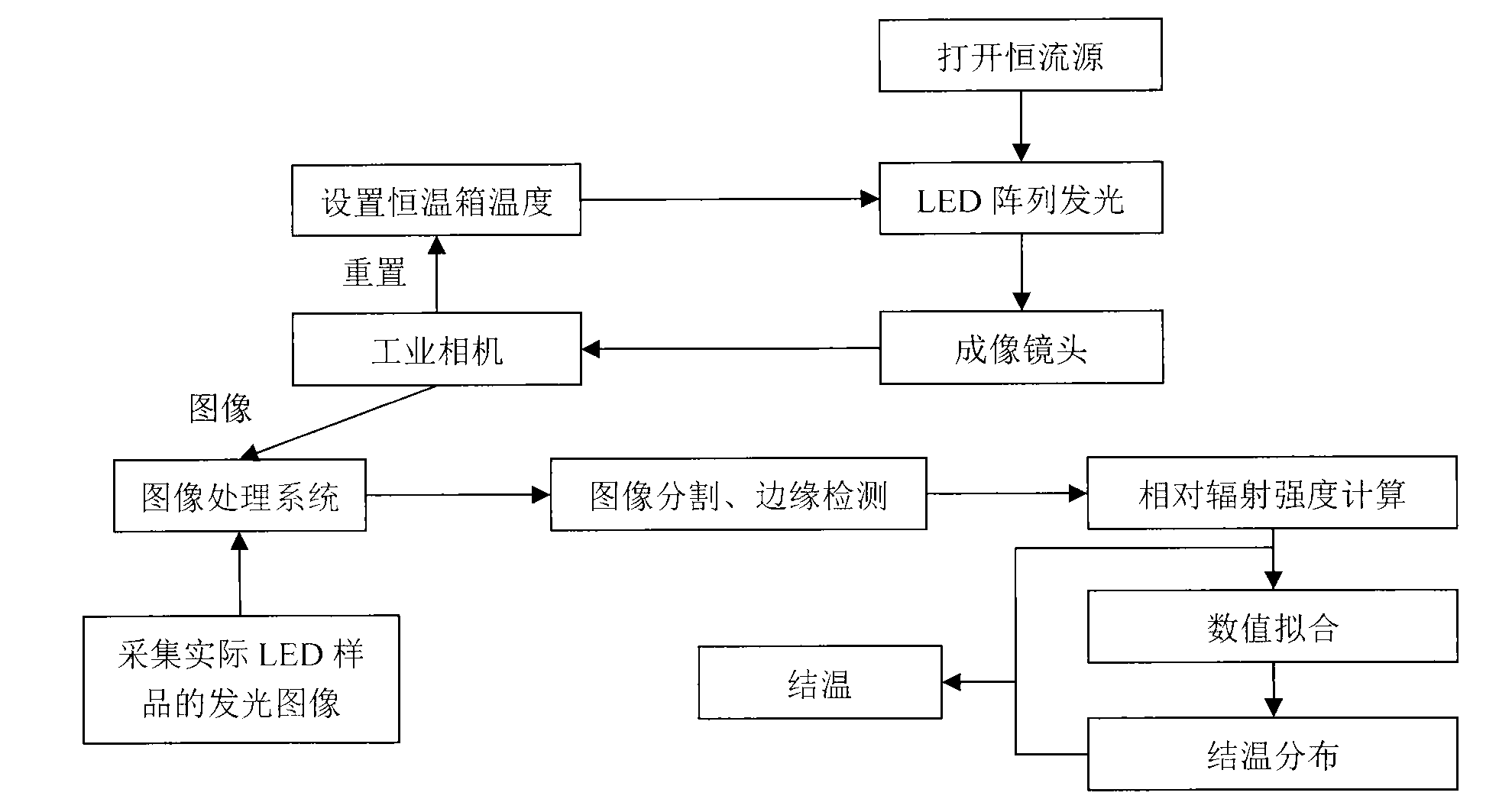

[0017] figure 1 , figure 2 Among them, the non-contact LED junction temperature test method: put the LED array 2 in the thermostat 3 with an initial temperature of 20°C for 20 minutes and stabilize it for 20 minutes. At this time, the temperature of the thermostat 3 is regarded as the initial junction temperature of the LED array 2. Turn on the constant current source 1 to drive the LED array 2 to emit light, collect the image of the LED array 2 under the temperature condition through the CMOS industrial camera 5 carrying the imaging lens 4, and transmit the image to the PC, and use the image processing system 6 to pair the collected The image is segmented and edge detected, and the area where each LED is located in the LED array 2 image is segmented, so that the size of each LED area is equal, and then the average value of the gray value of each LED area is calculated as the corresponding single LED For the relative radiation intensity, the relative radiation intensity of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com