Equipment monitoring system based on three-dimensional real scenes and system integration method based on three-dimensional real scenes

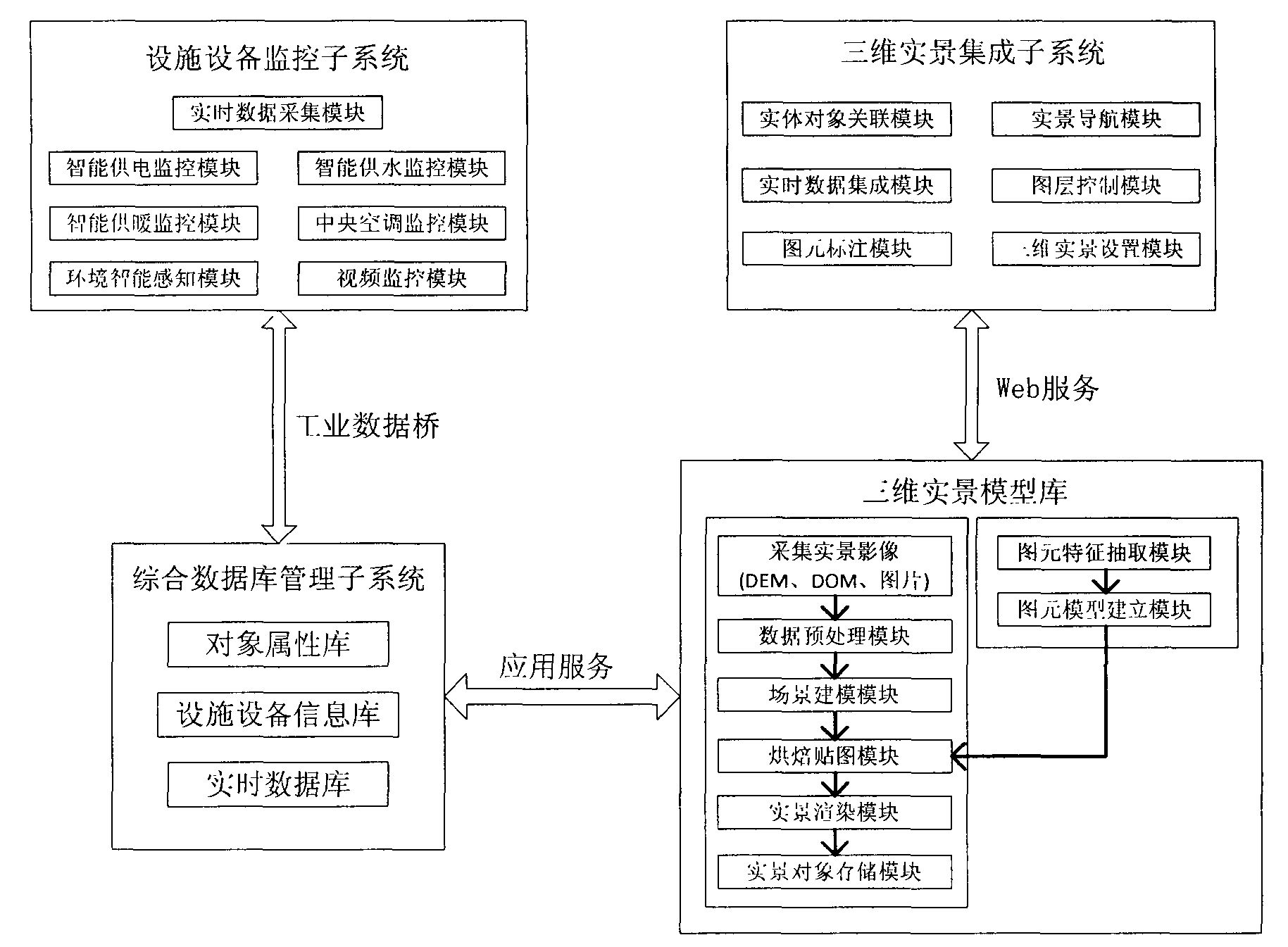

A device monitoring and three-dimensional technology, applied in the computer field, can solve the problems of insufficient integration, restricting the development of three-dimensional reality technology, and neglecting the modeling and identification of special primitives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] 1) Collect the digital elevation model (DEM), digital ortho image (DOM) and picture information of the actual scene in the area where a warehouse is located, and then use professional 3D production software (3DMarks, OpenGL, etc.) to preprocess the collected materials, Modeling, baking textures, rendering, and finally form a real and realistic scene effect of a certain warehouse, and the produced real-life photos, pictures, or video screenshots of the warehouse and other video materials, digital elevation models around the warehouse, digital orthophotos, The feature model of terrain and geomorphology, as well as physical simulation models such as buildings, water system greening, road pipelines, etc. are stored in the 3D real scene model library for calling by the 3D real scene integration subsystem;

[0054] 2) Utilize the graphic element feature extraction module to analyze the characteristics of various facilities and equipment for water supply, power supply, heating,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com