Electric rotating machine

一种旋转电机、转子的技术,应用在带有静止电枢和旋转磁体的同步电动机、同步机、电气元件等方向,能够解决电池容量有限、转速的上限限制、缩短可驱动时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

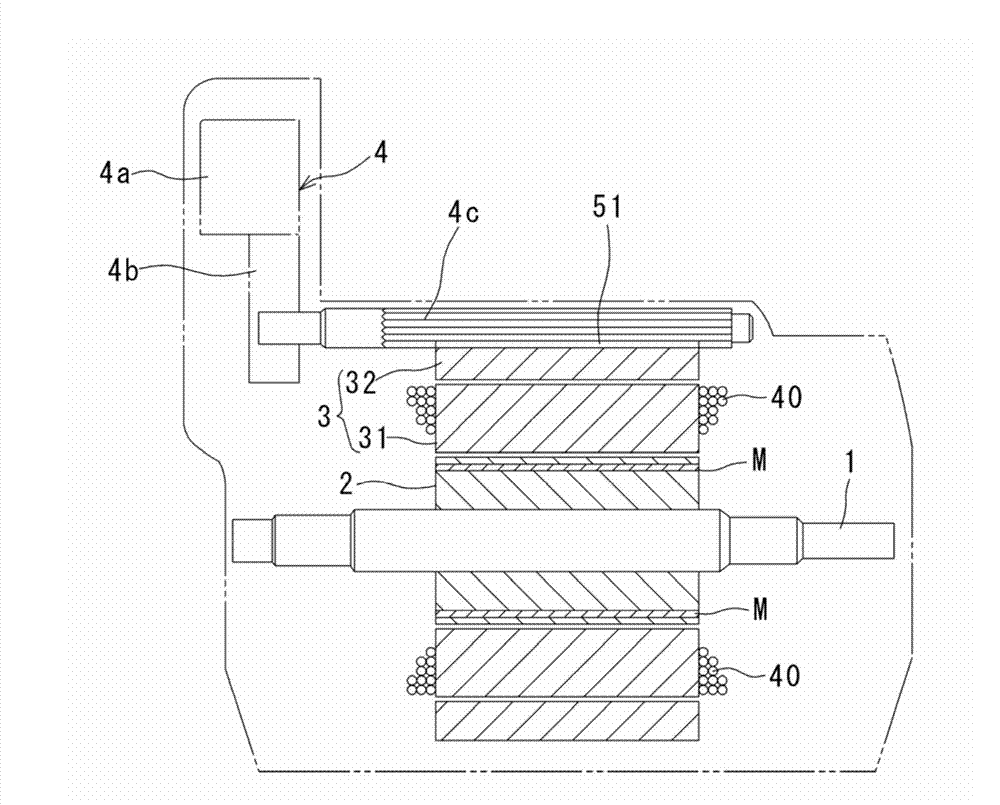

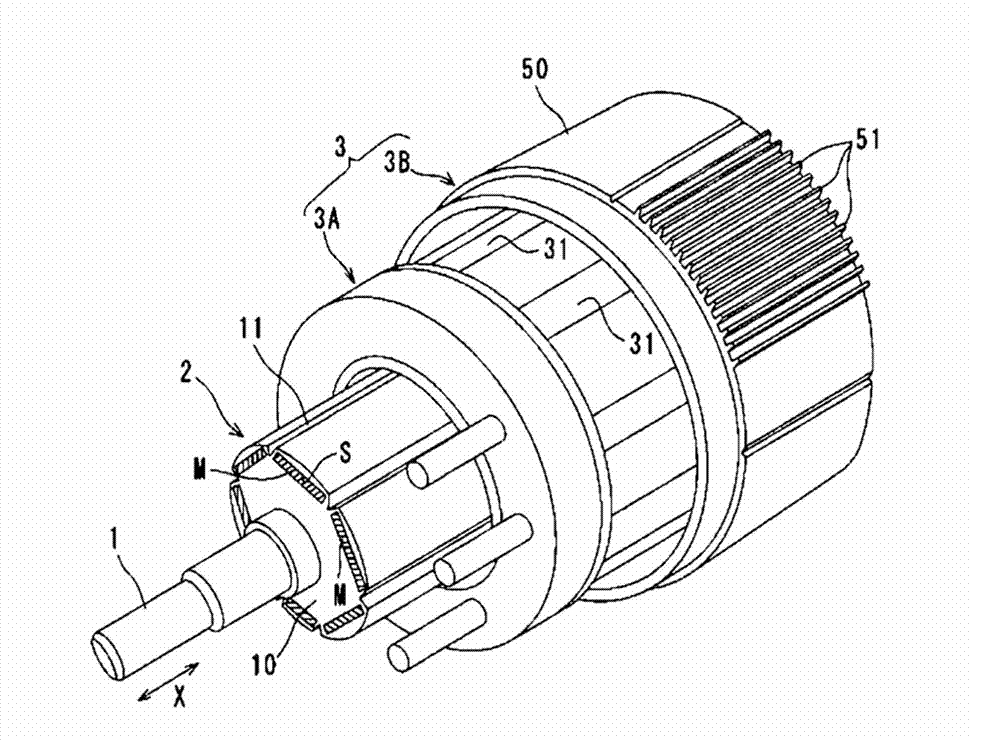

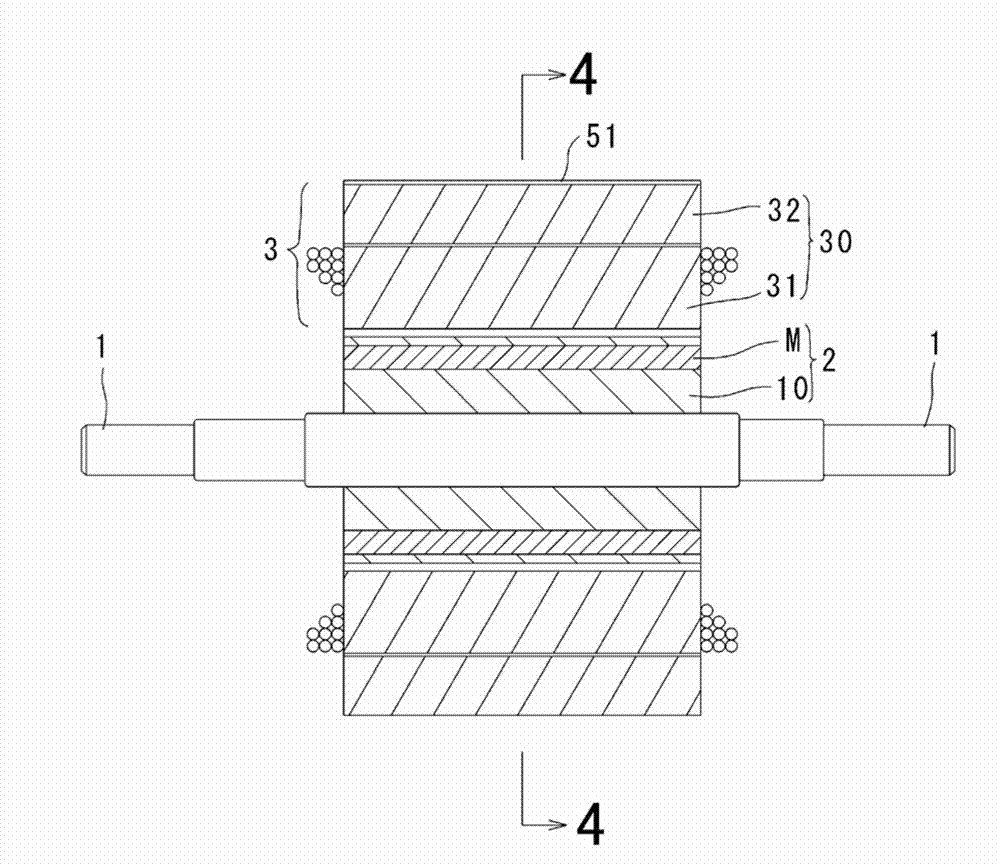

[0099] figure 1 to 6 schematically show a radial gap type motor used as a motor for an electric motorcycle according to a first embodiment of the present invention. As shown in these figures, this radial gap type motor includes a cylindrical rotor 2 having a cylindrical rotor 2 arranged at intervals in the circumferential direction on the outer peripheral portion in an embedded manner, a cylindrical stator 3 and a rotating mechanism 4 . A plurality of permanent magnets M and configured to rotate around the rotation axis 1, the cylindrical stator 3 faces the outer peripheral portion of the rotor 2 in the radial direction through a gap, and the rotation mechanism 4 is configured to make the components that constitute the stator 3 described later The movable split teeth move relatively. Such as figure 2 As shown, the rotor 2 comprises a cylindrical rotor body 10 having an axis of rotation 1 at its axial center. In the outer peripheral portion of the rotor main body 10 , a plu...

no. 2 example

[0155] A rotating electrical machine according to a second embodiment of the present invention is a radial gap type motor used as a motor for an electric motorcycle. The basic structure of this radial gap motor of this second embodiment is the same as that of the motor of the first embodiment except for the structure in which permanent magnets are mounted at the peripheral portion of the rotor 2 . Therefore, the following description will focus mainly on the differences.

[0156] in such as Figure 7 In the illustrated embodiment, each permanent magnet M corresponding to the permanent magnet M in the first embodiment is divided into two divided permanent magnets M1 and M1 arranged at intervals in the circumferential direction of the rotor 2 . On the radially outer side of these divided permanent magnets M1 and M1 , there is provided a holder 15 whose outer peripheral surface is formed in an arc shape. The holder 15 is integrally connected to the rotation center side of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com