Fe-based amorphous soft magnetic bulk alloy, method for fabricating same and applications thereof

A technology of amorphous alloy and manufacturing method, applied in magnetic materials, magnetic core manufacturing, metal processing equipment, etc., can solve the problems of high material loss rate, brittleness, size and thickness limitation, etc., to increase the application range and improve processing characteristics , Improve the effect of thickness size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

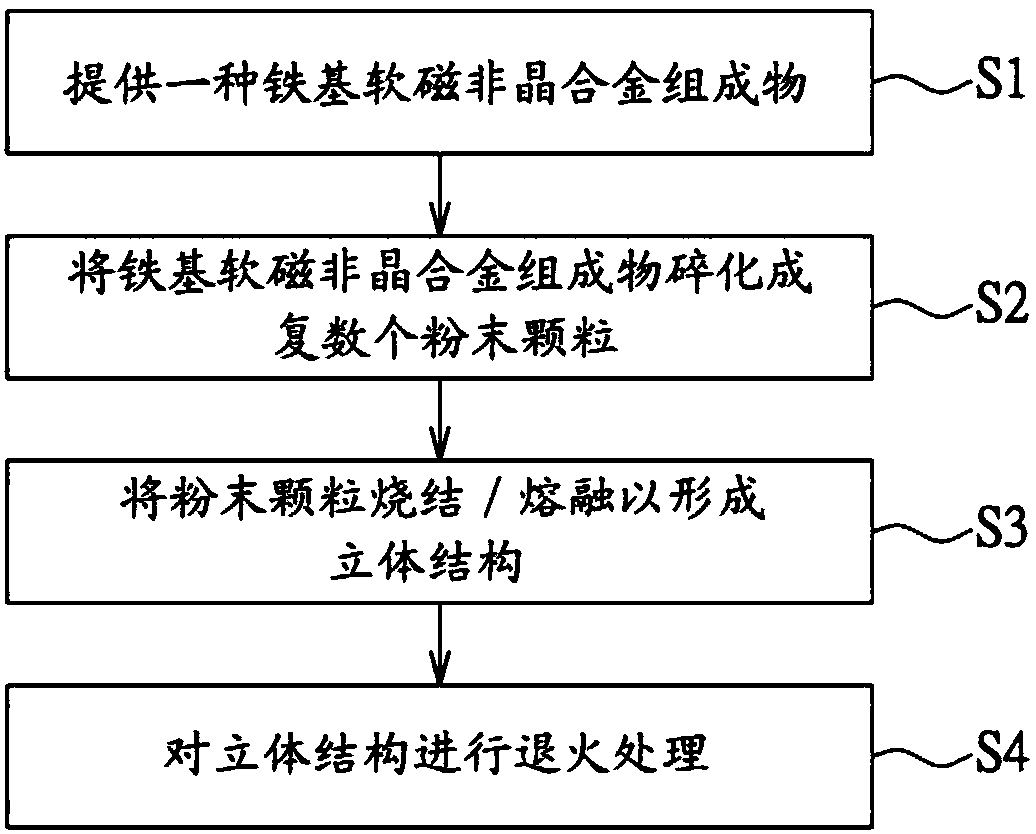

[0029] The embodiments disclosed in this specification relate to an iron-based soft magnetic amorphous alloy bulk material and its preparation method, which can solve the problem of excessive eddy current loss caused by the use of silicon steel cores in motor magnetic components in the prior art, and the use of iron-based soft magnetic amorphous alloys. The problem of poor processing characteristics of crystal alloy materials. In order to make the above purpose, features and advantages of this specification more comprehensible, several preferred embodiments are specifically cited and described in detail as follows with the accompanying drawings.

[0030] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The invention can still be implemented with other features, elements, methods and parameters. The preferred embodiments are presented only to illustrate the technical features of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com