Device for tightening threaded fasteners

A fastener and reaction technology, applied in the direction of portable motorized devices, screwdrivers, wrenches, etc., can solve the problems of inaccuracy, achieve high inertia, and improve the effect of torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

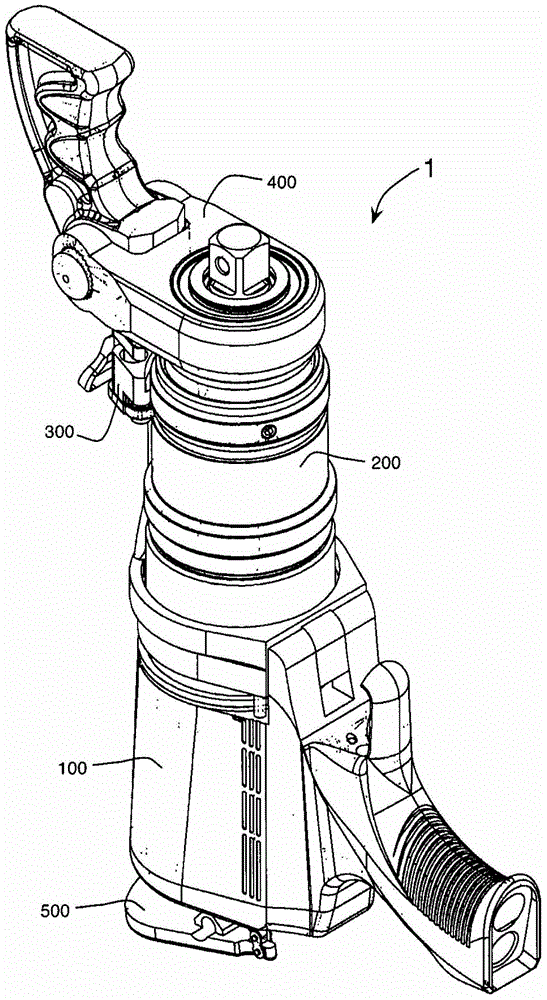

[0030] For example refer to figure 1 , which shows a perspective view of a device 1 for counterforce-free and counterforce-assisted tightening and loosening of industrial fasteners according to an embodiment of the present invention. The device 1 comprises a drive assembly 100 , a reinforcement assembly 200 , a gear / mode switching assembly 300 , a rotation / turning reaction assembly 400 and a safety assembly 500 .

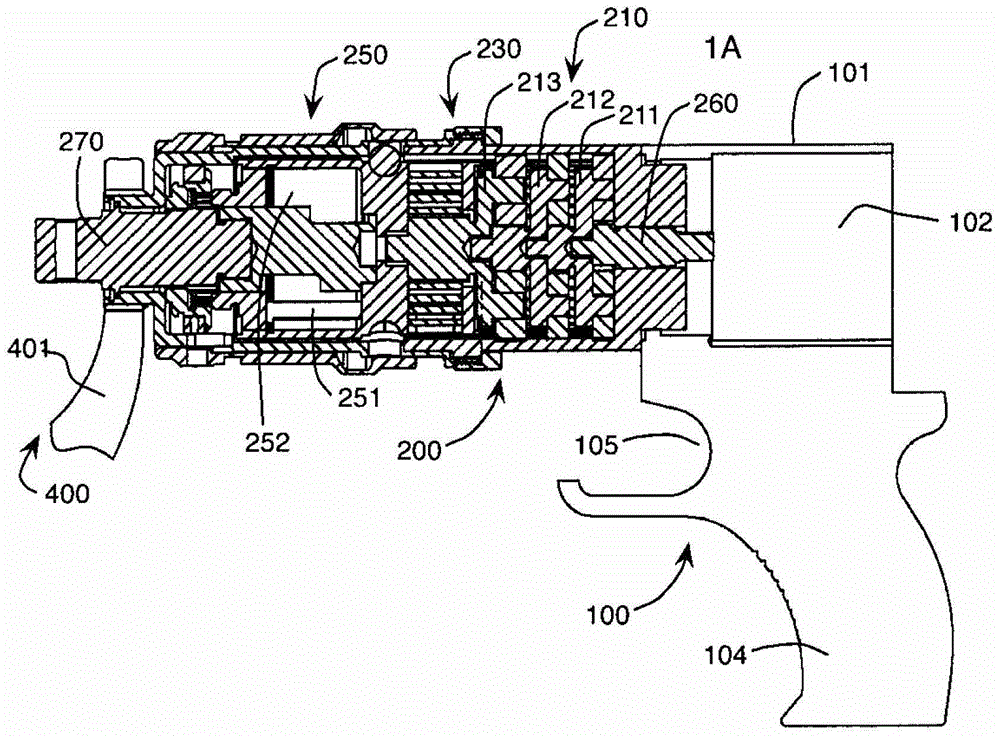

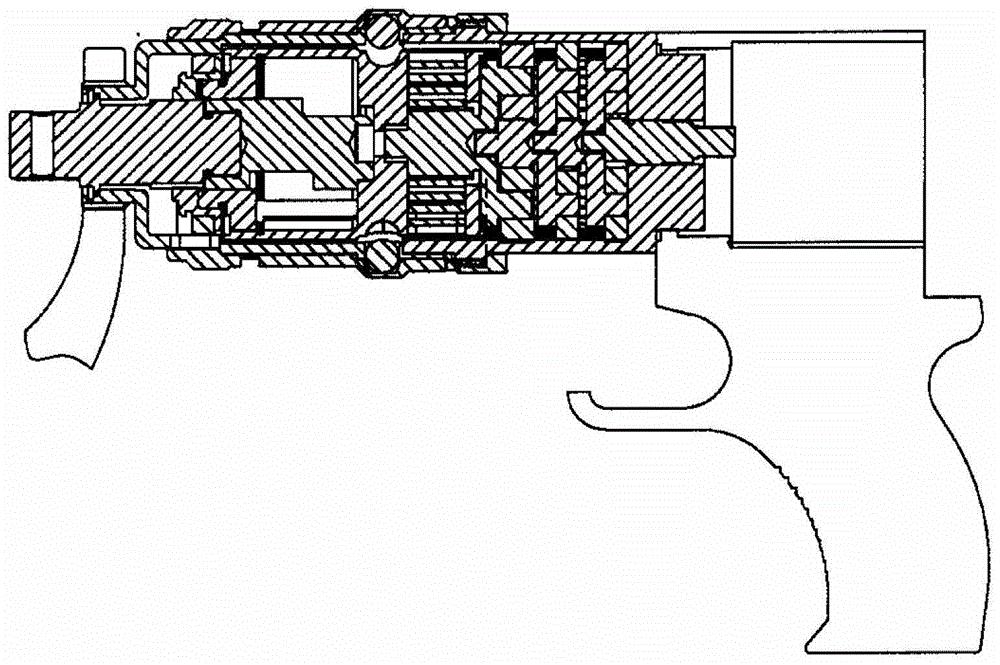

[0031] For example refer to figure 2 , which shows a cross-sectional view of a device 1A according to an embodiment of the present invention. Device 1A is similar to device 1 and as indicated by the same reference numerals.

[0032] The driving assembly 100 may include a driving housing 101 , a driving mechanism 102 , a handle 104 and a switching mechanism 105 . The drive 102 generates a rotational force to rotate the fastener and is shown shaped as a motor drive including a motor. The driving mechanism 102 can also be formed as a manual driving mechanism, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com