Production technology of soybean sprout

A production process, soybean sprout technology, applied in the field of vegetable industrial production technology, can solve the problems of high labor intensity, low efficiency, and unable to produce bean sprouts normally, and achieve the effect of weakening mildew and improving rationalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

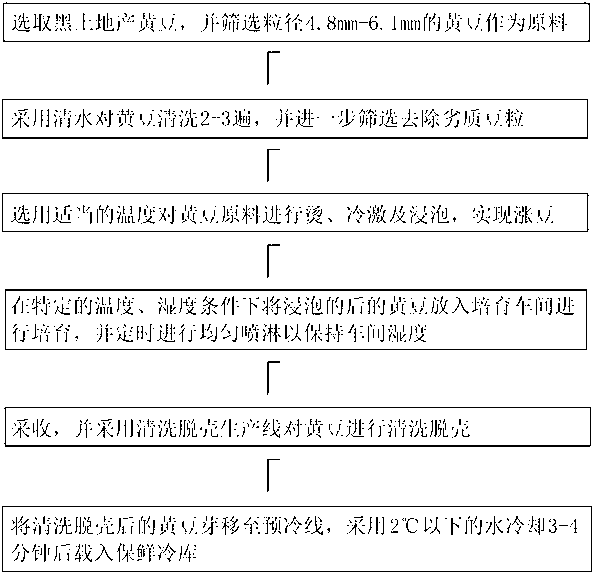

Method used

Image

Examples

Embodiment 1

[0026] Select the soybeans obtained from the black soil farmland in Heilongjiang Province, and screen the soybeans with a diameter of 4.8mm; wash the soybeans 2-3 times with clean water, remove insect-eaten, broken, deformed, mildewed, sprouted, and immature particles, and wash them Sediment and impurities are removed; directly soak the beans in clean water at 20°C for 5 hours to rise the beans. After soaking the beans, wash them 2-3 times and rub, rinse, and rinse off the mucus on the surface of the soybeans and remove the rotten beans. The weight of the raw soybeans is twice the weight; the soaked soybeans are transported to the cultivation workshop and placed in cultivation tanks for 6 days of dark cultivation. The weight of soybeans is 130kg per tank. The indoor temperature of the cultivation workshop is kept at 23°C and the relative humidity is kept at 80 % and spray the cultivation tank evenly every 4 hours; move the cultivation tank out of the cultivation workshop accord...

Embodiment 2

[0028] Select the soybeans obtained from the black soil farmland in Heilongjiang Province, and screen the soybeans with a diameter of 5.4mm; wash the soybeans 2-3 times with clean water, remove insect-eaten, broken, deformed, mildewed, sprouted, and immature particles, and wash them Sediment and impurities are removed; directly soak the beans in clean water at 23°C for 5.5 hours to rise the beans. After soaking the beans, wash them 2-3 times and rub, rinse, and rinse off the mucus on the surface of the soybeans and remove the rotten beans. The weight of raw soybeans is twice the weight; transport the soaked soybeans to the cultivation workshop and put them into cultivation tanks for 7 days of dark cultivation. The weight of soybeans is 130kg / can. The indoor temperature of the cultivation workshop is kept at 25°C and the relative humidity is kept at 80 % and spray the cultivation tank evenly every 3 hours; move the cultivation tank out of the cultivation workshop according to th...

Embodiment 3

[0030] Select soybeans obtained from the black soil farmland in Heilongjiang Province, and screen soybeans with a diameter of about 6mm; wash the soybeans with clean water 2-3 times, remove moth-eaten, broken, deformed, mildewed, sprouted, and immature particles, and wash them Sediment and impurities are removed; directly soak the beans in clean water at 25°C for 6 hours to grow the beans. After soaking the beans, wash them 2-3 times and rub, rinse, and rinse off the mucus on the surface of the soybeans and remove the rotten beans. The weight of raw soybeans is twice the weight; transport the soaked soybeans to the cultivation workshop and put them into cultivation tanks for 7 days of dark cultivation. The weight of soybeans is 130kg / can. The indoor temperature of the cultivation workshop is kept at 25°C and the relative humidity is kept at 80 % and spray the cultivation tank evenly every 2 hours; move the cultivation tank out of the cultivation workshop according to the hypoco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com