Double plane servo riveting device

A working device and double-plane technology, which is applied in the field of double-plane servo riveting working devices, can solve the problems of limited scale, underutilized machine operation, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

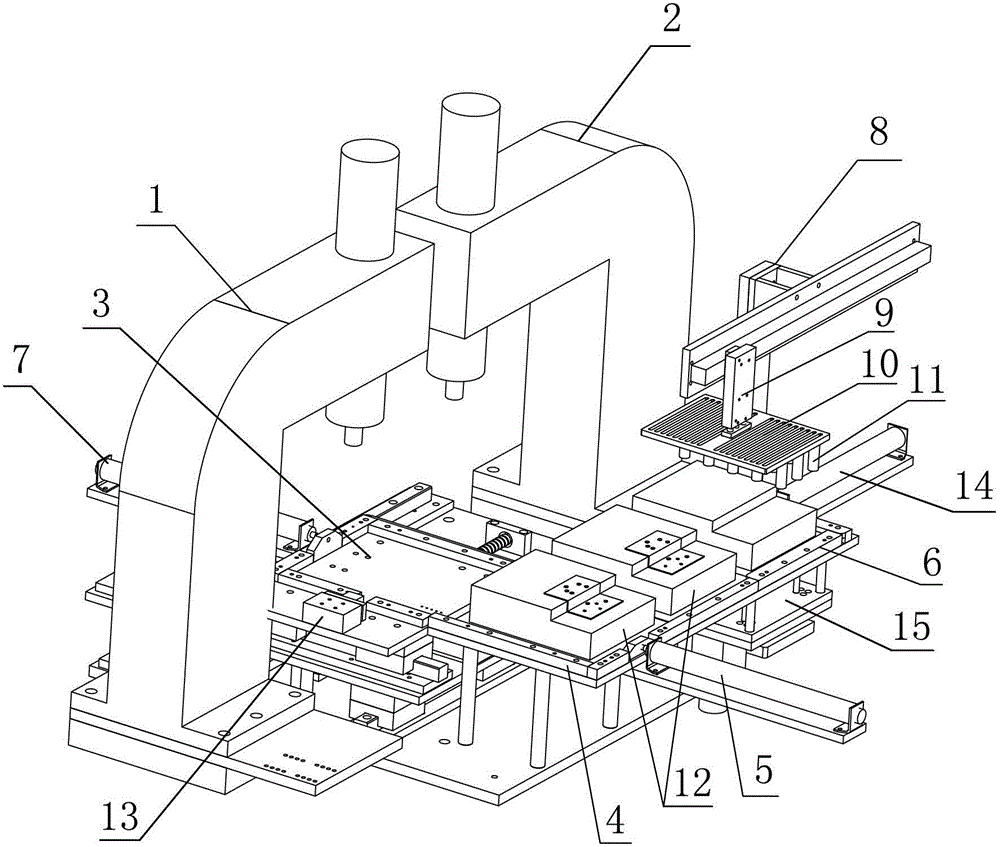

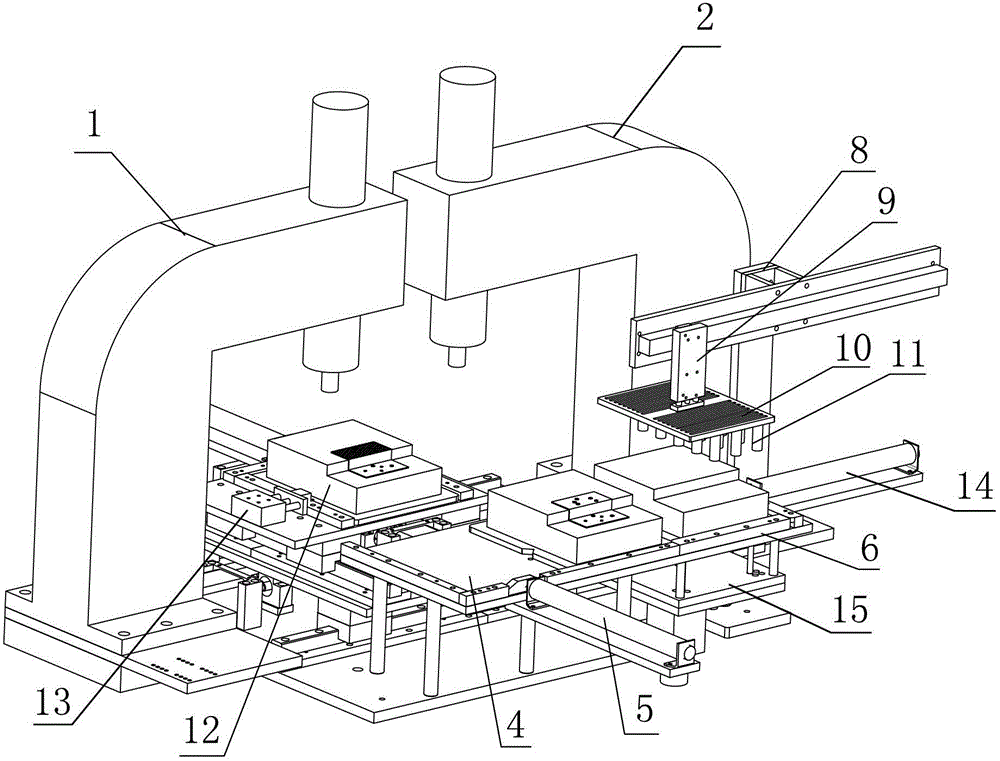

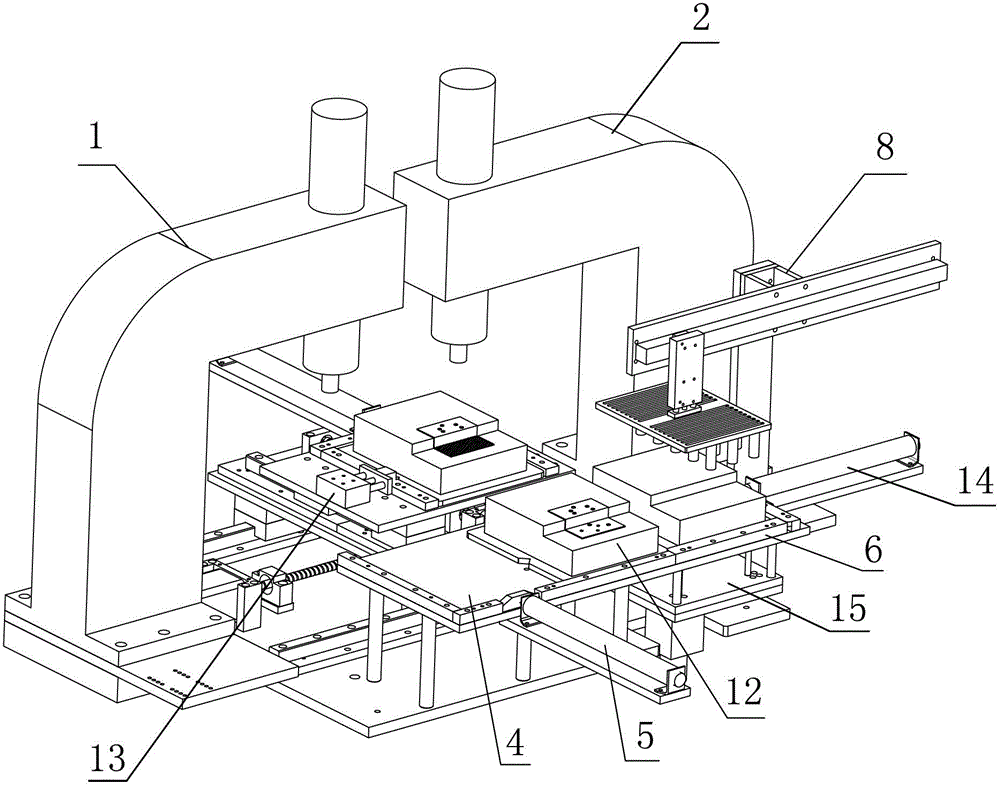

[0022] refer to Figure 1 to Figure 4 As shown, the present invention discloses a dual-plane servo riveting operation device, which can perform rivet processing on two different planes of the same part; it includes a rivet device, a servo working platform, a feeding device, an unloading device, and a manipulator device . A clamping device, wherein the riveting device includes a first riveting machine 1 for riveting on a first plane and a second riveting machine 2 for riveting on a second plane (the first plane and the second planes are two different planes on the workpiece), the first riveting machine 1 and the second riveting machine 2 are set opposite; the servo working platform includes a first servo motor, a second servo motor, an X-axis ball screw, a Y-axis The roller screw and the platform carrier 3 that can move along the X-axis and Y-axis di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com