Rope coring and arranging winch with heavy hook falling freely

A rope coring and winch technology, applied in hoisting devices, spring mechanisms, etc., can solve problems such as drum surface scratches, shortened service life of steel wire ropes, and disordered rope arrangement, and achieves compact structure of the winch, safe and reliable operation, and The effect of wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

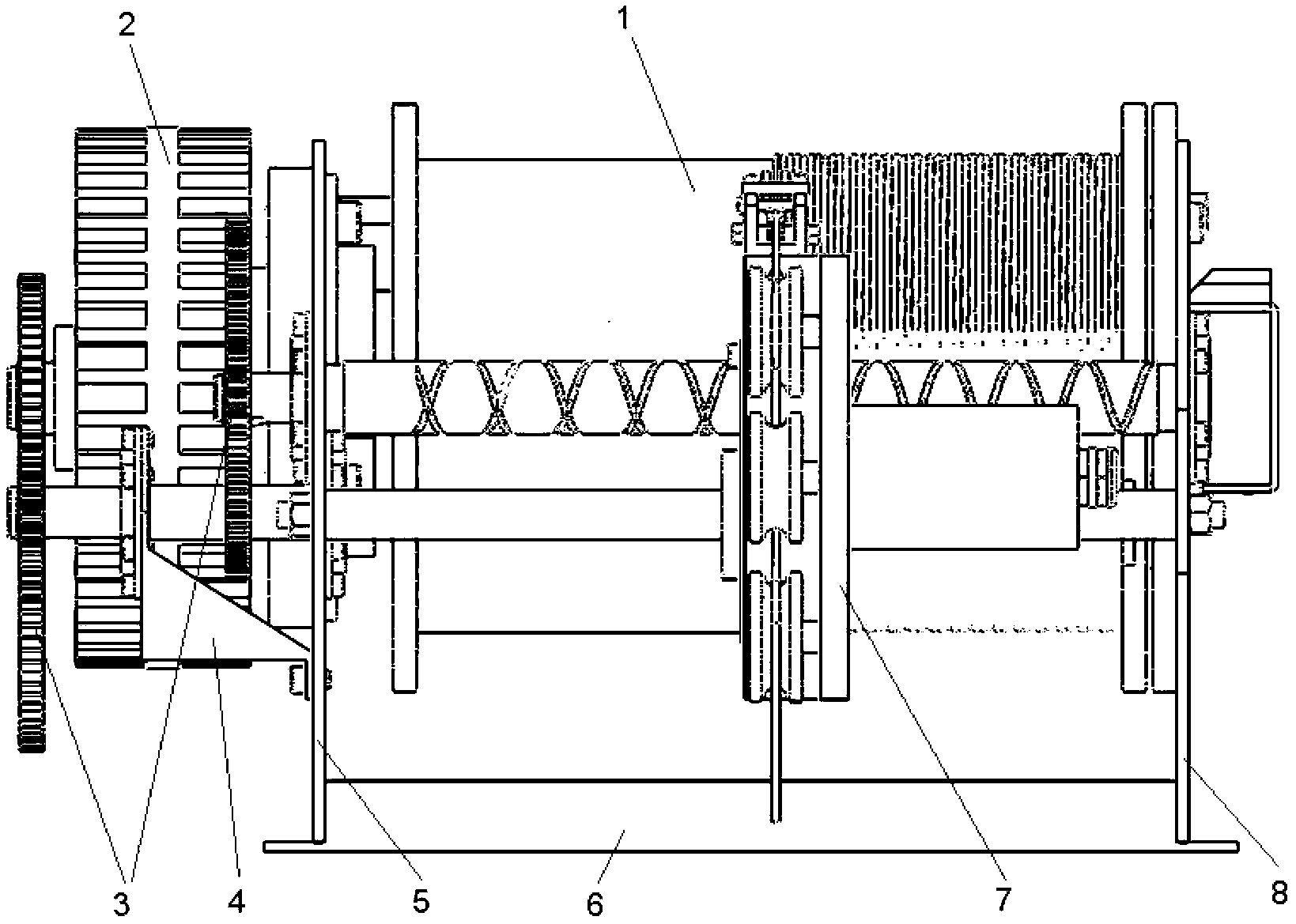

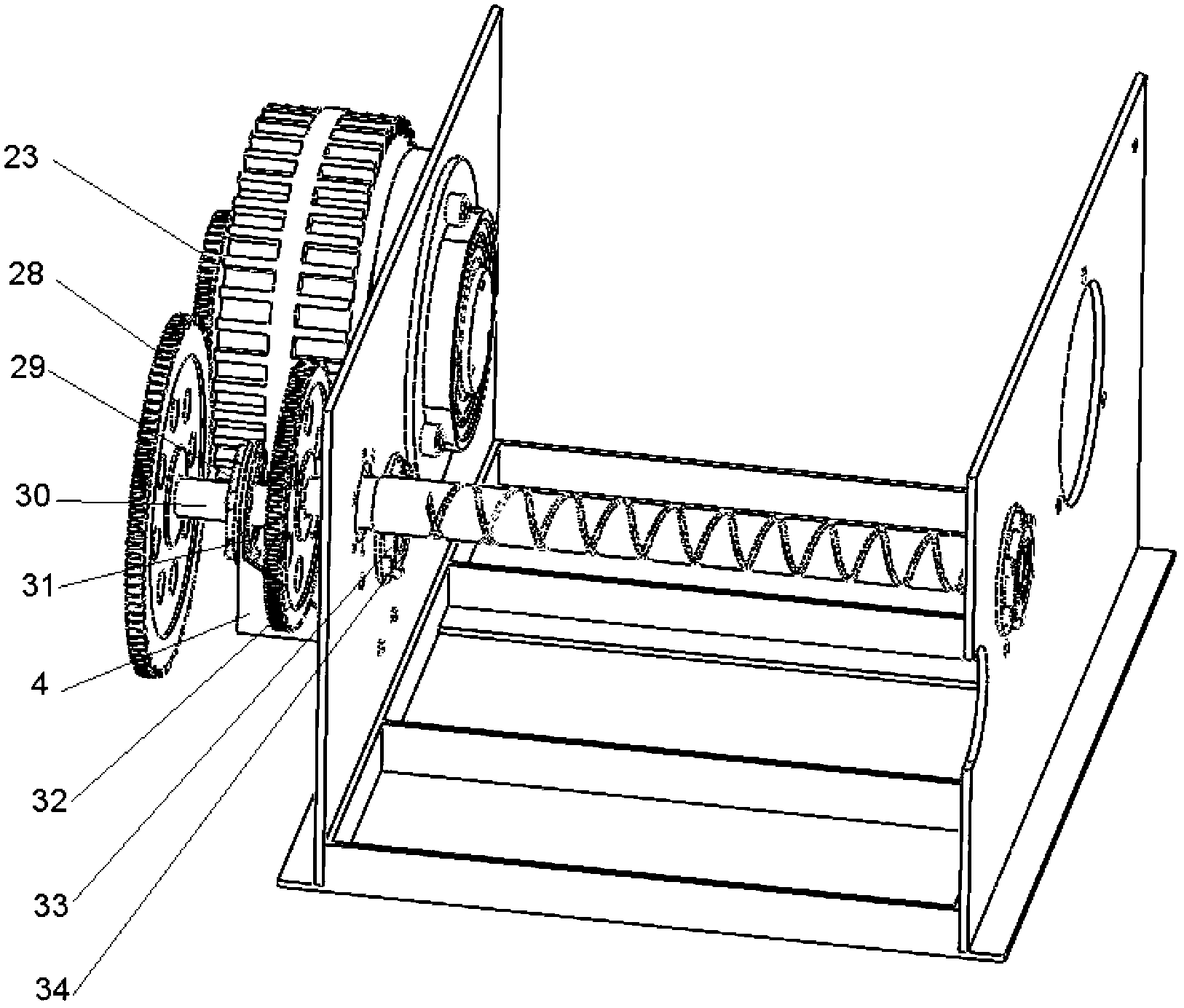

[0037] Embodiment 1: A kind of heavy hook free-falling rope coring winch of the present invention, its structure is as follows figure 1 As shown, it includes drum assembly 1, brake 2, hanging wheel speed regulating chain 3, gear shaft support 4, left support plate 5, base 6, rope puller 7, right support plate 8. The drum assembly 1 has a brake 2 connected to its left end, and the left end of the output shaft of the brake is connected to the outer pinion 23 of the hanging wheel speed regulating chain 3, and the output end of the hanging wheel speed regulating chain is the two-way Screw rod, reel assembly 1, rope puller 7 are fixed on the base 6 by left support plate 5, right support plate 8; Base 6 is welded by section steel.

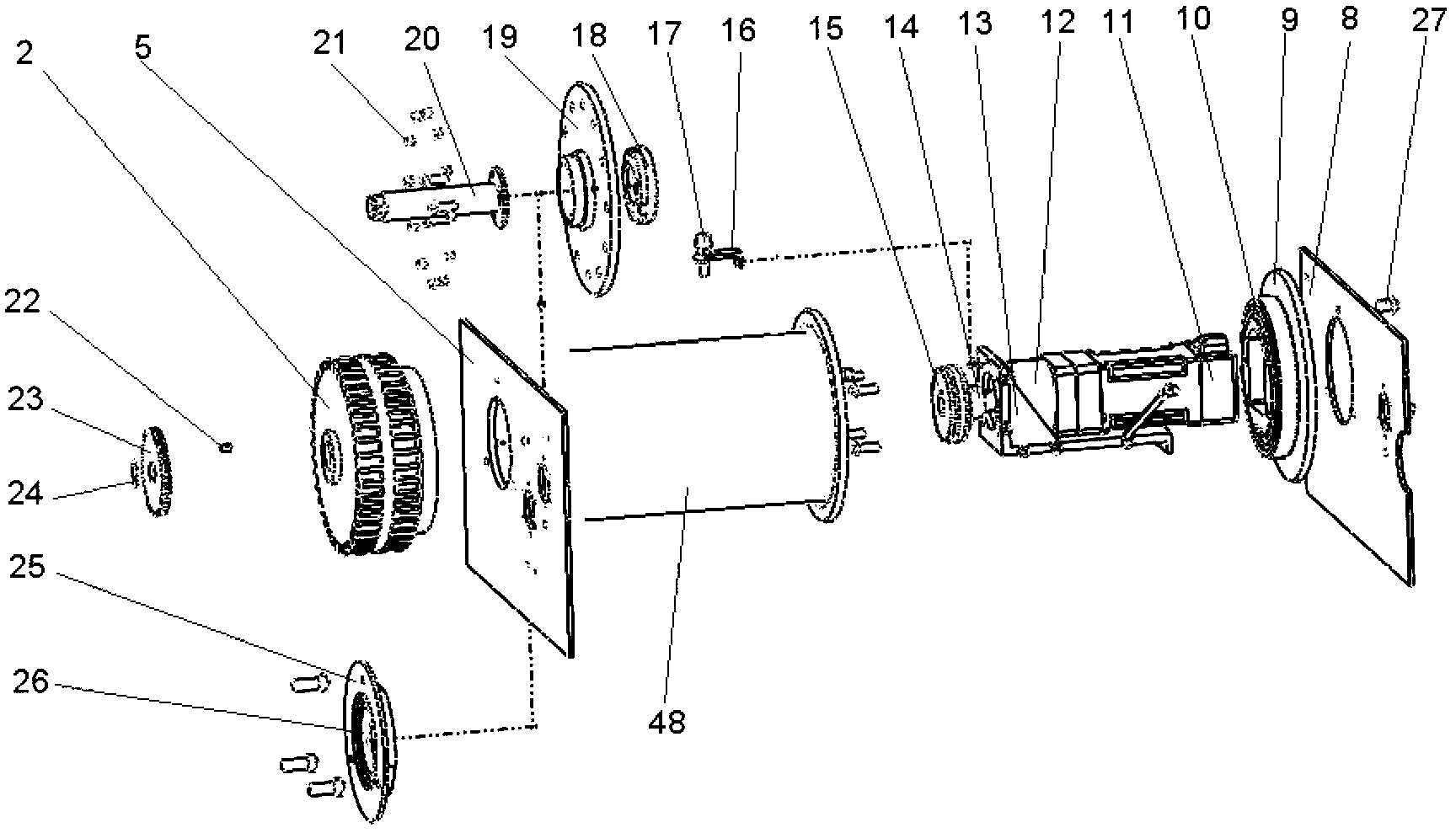

[0038] like figure 2As shown, the drum assembly 1 includes the drum right end cover 9, bearing A10, servo motor 11, planetary reducer 12, power bracket 13, sleeve 14, right flap clutch 15, brush bracket 16, brush 17 , left flap clutch 18, drum left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com