Double rotary wedge variable pitch pneumatic valve actuator

A technology of pneumatic valves and actuators, applied in valve details, valve devices, engine components, etc., can solve the problems of inability to effectively solve the problems of stator and rotor sealing, excessive output torque margin, and increase in the volume of pneumatic devices. The effect of small faults, simple and compact structure, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

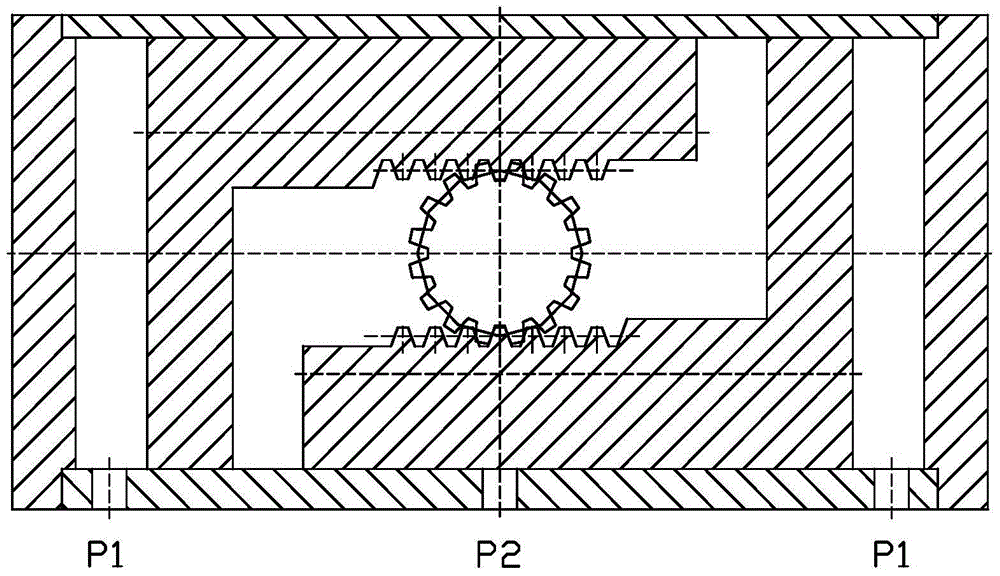

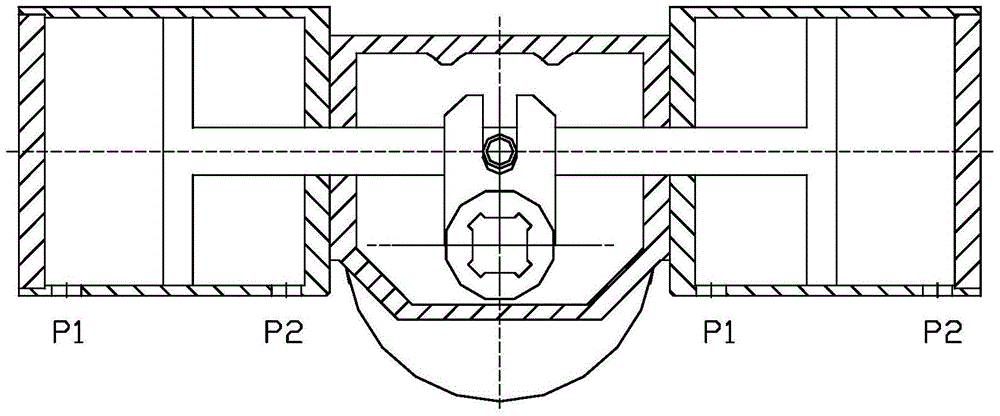

[0042] Please refer to Figure 7-9 One embodiment of the double-rotary wedge variable pitch pneumatic valve actuator of the present invention includes a housing and a main shaft 1 and a piston 11 arranged in the housing. The main shaft 1 is located in the middle of the housing, and the piston 11 is installed on the periphery of the main shaft 1. 11 The axial up and down movement in the housing is realized by the air source pressure.

[0043]Described casing comprises the box body 15 that is positioned at the bottom and the box cover 4 that is positioned at the top, and inner and outer sealing ring (2,7,10,18) is housed on box body 15 and box cover 4, box body 15 and box cover 4 pass screw 21 is fixedly connected, and forms the support at both ends of the main shaft 1 through rolling bearings (3, 17). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com