Directional reflective material and preparation method thereof

A technology of reflective materials and raw materials, applied in the direction of reflective/signal coatings, coatings, layered products, etc., can solve the problems of narrow reflective visibility range, and achieve the effects of small impact, strong reflectivity, and wide visibility range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further described in detail below in conjunction with examples of specific implementations.

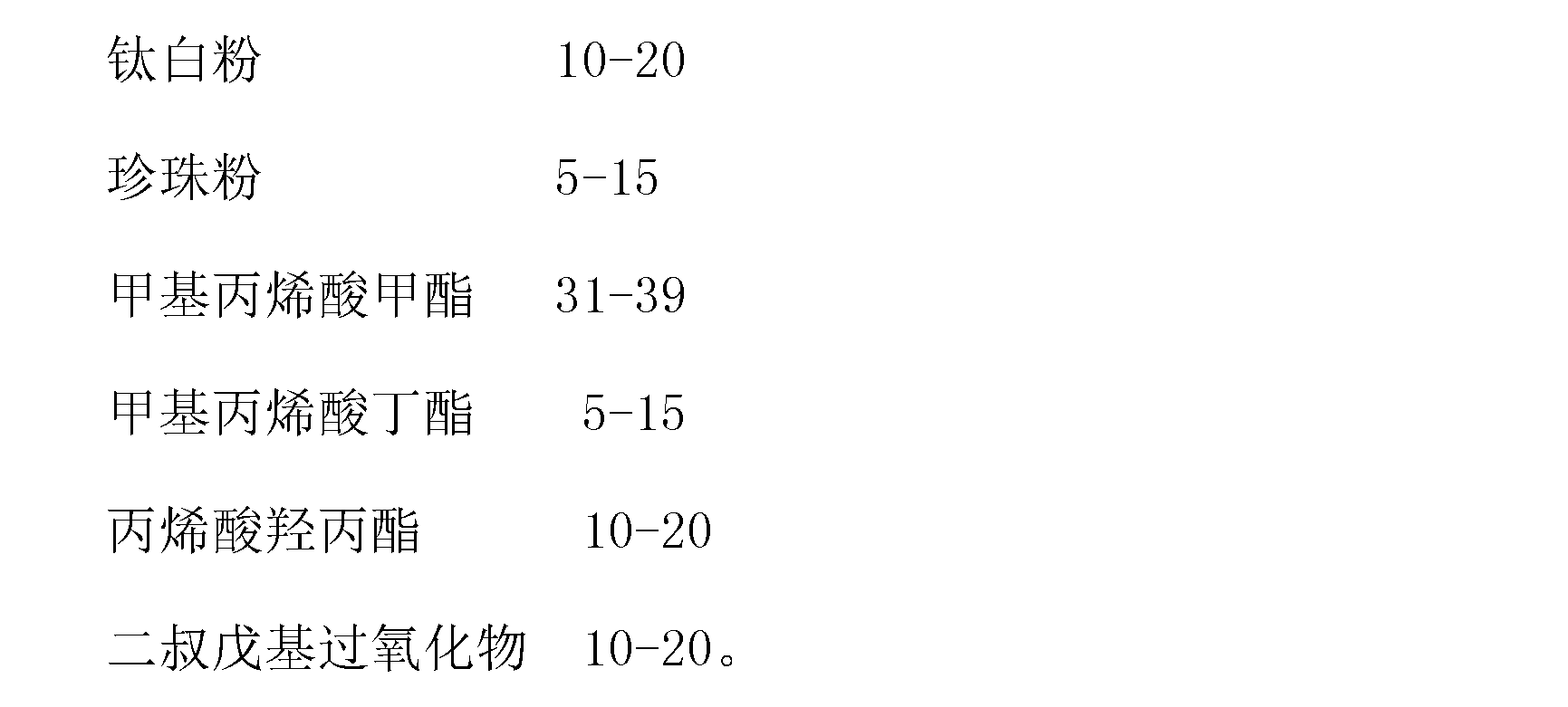

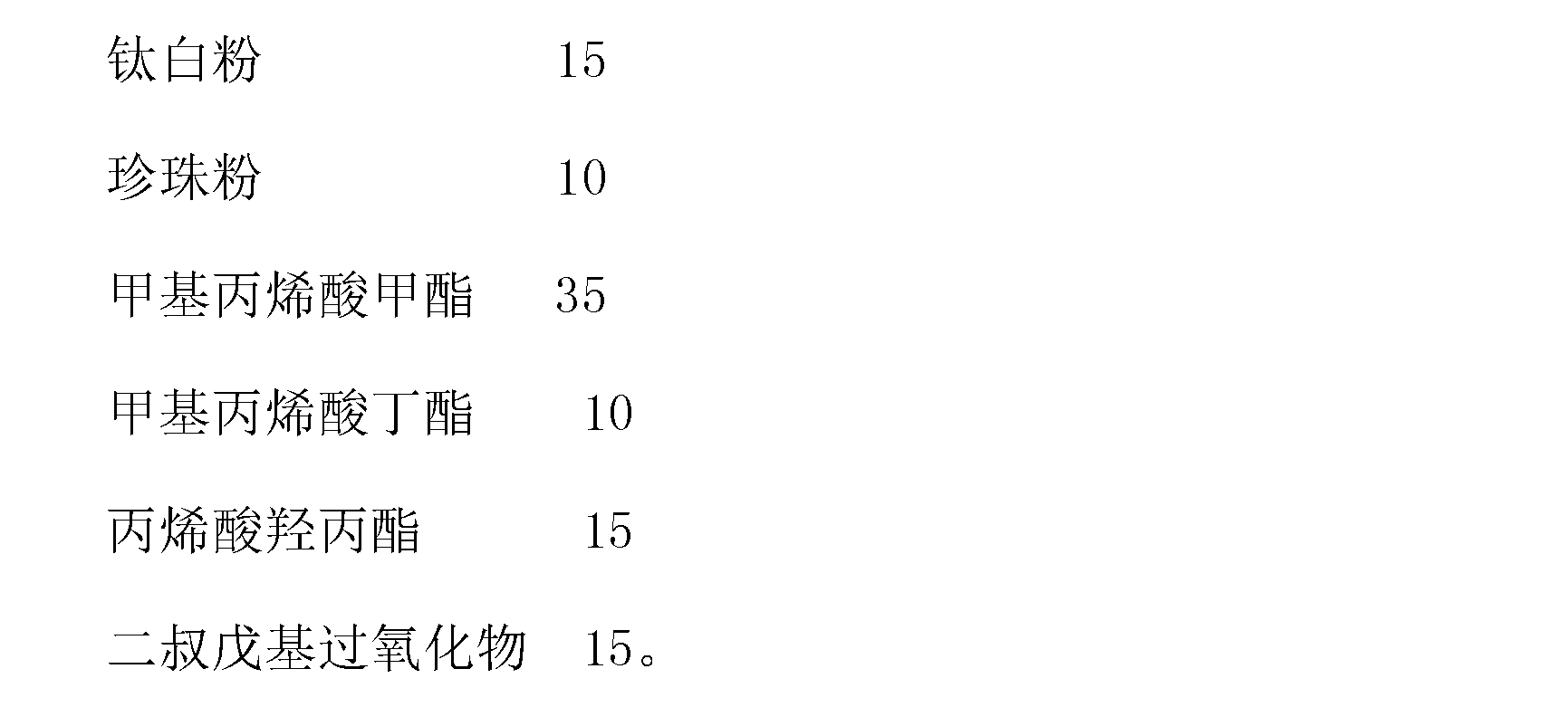

[0021] a. Weigh the raw materials according to the weight ratio, 15g titanium dioxide, 10g pearl powder, 35g methyl methacrylate, 10g butyl methacrylate, 15g hydroxypropyl acrylate, 15g di-tert-amyl peroxide;

[0022] b. Stir the weighed titanium dioxide and pearl powder evenly and put it aside for later use;

[0023] c. Put methyl methacrylate, butyl methacrylate, and hydroxypropyl acrylate into the reactor for mixing and stirring. After mixing and stirring for 3 minutes, add di-tert-amyl peroxide to the reactor. Stir intermittently, and the dripping time is 2 hours;

[0024] c. After the di-tert-amyl peroxide is added dropwise, put the stirred titanium dioxide and pearl powder into the reaction kettle, stir well, stir e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com