Polyester reflecting film for large-size thin display

A reflective film and display technology, which is applied in the field of polyester film manufacturing, can solve the problems of low light utilization rate, attenuation of film mechanical and mechanical properties, poor stiffness and toughness, etc., so as to improve mechanical and mechanical properties and improve application feasibility , the effect of high effective reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

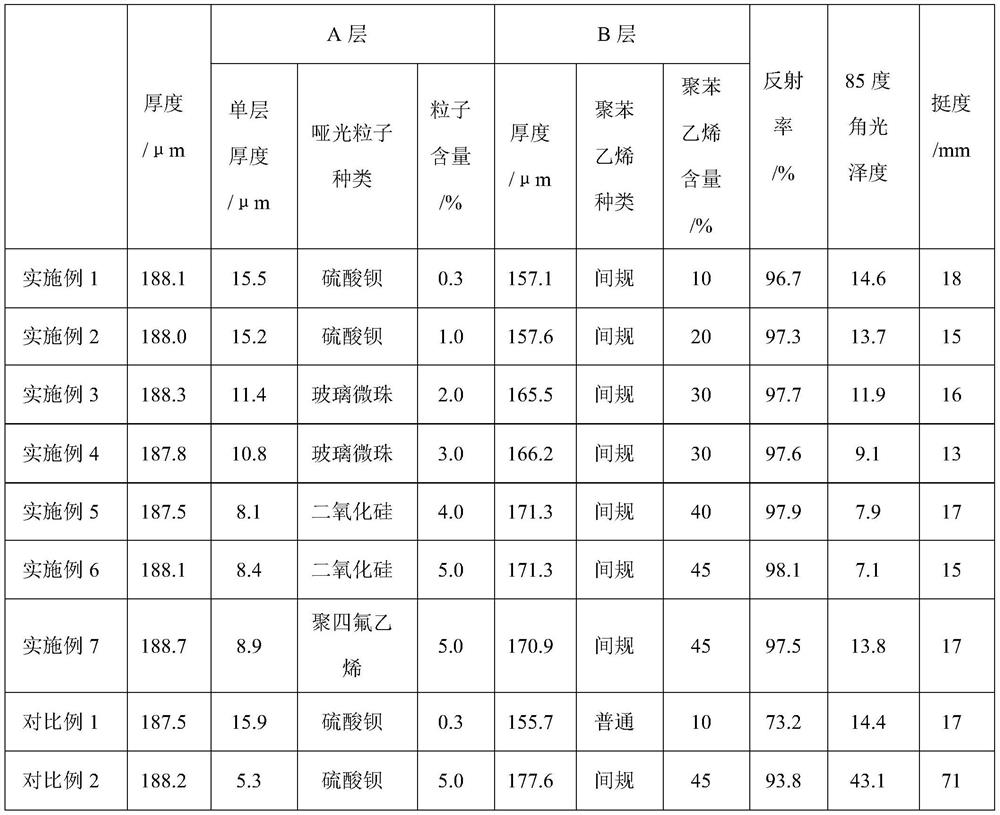

Embodiment 1

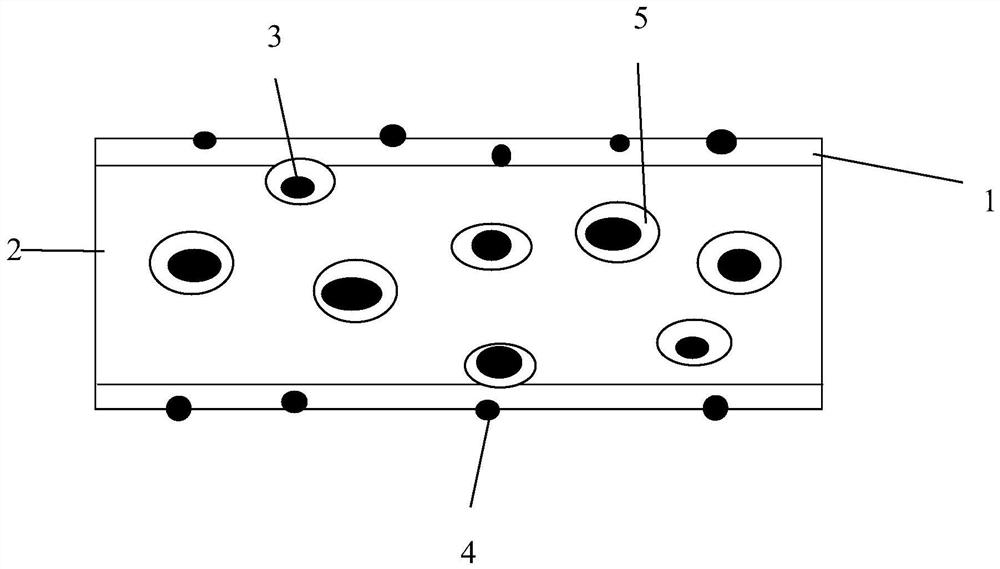

[0062] On a multi-layer co-extrusion film-making plant with extruder (a) and extruder (b), in order to form a matte layer (A layer), the pre-mixed masterbatch (A) and virgin polyester chips are , supplied to the extruder (a), melt-extruded at 280° C., and introduced into a T-die. In order to form the reflective layer (B layer), the pre-mixed masterbatch (B) and pure polyester chips are supplied to the extruder (b), melted and extruded at 280°C, and introduced into a T-die. The extruder (a) and the extruder (b) extrude synchronously and lead into the T die head synchronously.

[0063] In the T-die head, the melt of the extruder (a) is evenly distributed to both sides of the melt of the extruder (b), and the two sets of melts are laminated according to the A / B / A three-layer structure Converge and flow in sheet form on a rotating cold drum with a surface temperature of 20°C to obtain a laminated cast film. The laminated cast film is preheated at 70-85°C, and stretched longitudi...

Embodiment 2

[0073] Use the same equipment and process conditions as in Example 1.

[0074] In this example,

[0075] Raw material ratio of layer A is, masterbatch (A): pure polyester chips = 33:67

[0076] Raw material ratio of layer B is, masterbatch (B): pure polyester chips = 50:50

[0077] The ratio of layer A to layer B is, layer A:layer B=200:1000

[0078] in,

[0079] Pure polyester chip: same as embodiment 1.

[0080] Masterbatch (A): Same as Example 1.

[0081] Masterbatch (B): Same as Example 1.

Embodiment 3

[0083] Use the same equipment and process conditions as in Example 1.

[0084] In this example,

[0085] Raw material ratio of layer A is, masterbatch (A): pure polyester chips = 20:80

[0086] Raw material ratio of layer B is, masterbatch (B): pure polyester chips = 50:50

[0087] The ratio of layer A to layer B is, layer A:layer B=200:1500

[0088] in,

[0089] Pure polyester chip: same as embodiment 1.

[0090]Masterbatch (A): the content of matte particle glass microspheres is 10%; the refractive index of glass microspheres is 1.51.

[0091] Master batch (B): syndiotactic polystyrene content 60%; syndiotactic polystyrene, DSC test, melting point Tm = 269 ° C, glass transition temperature Tg = 99 ° C; nuclear magnetic resonance test, structural unit regularity 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com