Reflective sheet and backlight unit

A technology for a backlight unit and a reflective sheet, applied in the field of reflective sheets, can solve the problems of uneven brightness, scratches on the light guide plate, bending of the reflective sheet, etc., and achieve the effect of high reflectivity and improved reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073] The above-mentioned embodiment has the above-mentioned advantages due to the above-mentioned structure, but the present invention is not limited to the structure of the above-mentioned embodiment, and the design can be appropriately changed within the scope of the purpose of the present invention.

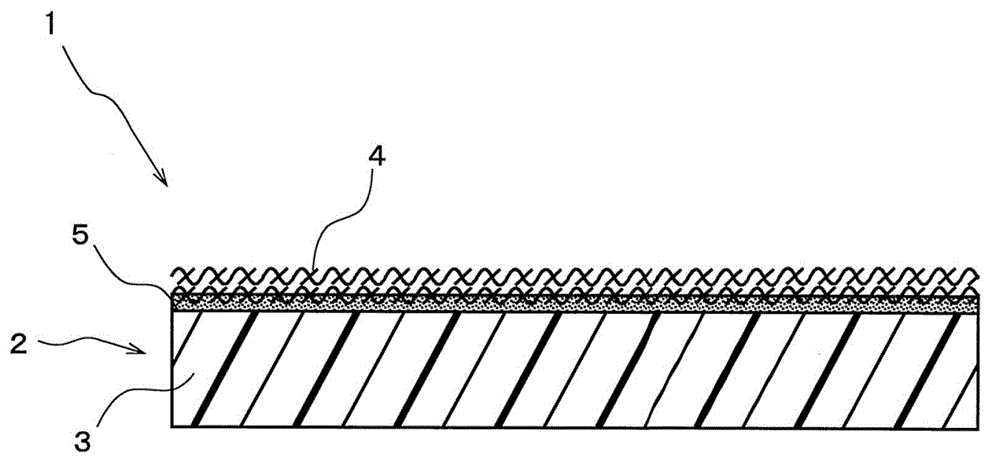

[0074] That is, in the above-mentioned embodiment, any one of the fiber gathering layer 4, the adhesive layer 5, and the sheet main body 2 has been described as being white, but the present invention is not limited thereto, as long as the desired reflectivity can be obtained. The design can be changed appropriately. Specifically, even if the fibers of the fiber accumulation layer 4 are colorless and transparent, and the white pigment is dispersed and contained in the adhesive layer 5, the reflective sheet 1 is within the scope of the object of the present invention. By dispersing and containing the white pigment in the adhesive layer 5 in this way, sufficient reflectivity ca...

Embodiment 1

[0081] A sheet made of white PET (polyethylene terephthalate) ("Lumira-E60L" manufactured by Toray Co., Ltd.) was used for the sheet main body (substrate sheet layer). The reflective sheet of Example 1 was fabricated by laminating and bonding a nonwoven fabric ("Taibeck" manufactured by DuPont) on the surface of the sheet main body by dry lamination. Here, as the adhesive for bonding the nonwoven fabric, a dry lamination adhesive ("E263" manufactured by Dainichi Seika Co., Ltd.) was mixed with 90% by mass of titanium oxide. The stacking amount of the mixture layer (converted into solid content) is 10g / m 2 .

Embodiment 2

[0083] The reflective sheet of Example 2 was obtained by the same method as in Example 1 except that no titanium oxide was mixed with the adhesive for dry lamination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com