Water-phase method for preparing surface modified functional cadmium sulfide ultrafine particles

A technology of surface modification and cadmium sulfide, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems that nano-scale powders are not easy, and achieve the effects of efficient preparation, easy operation of reaction, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

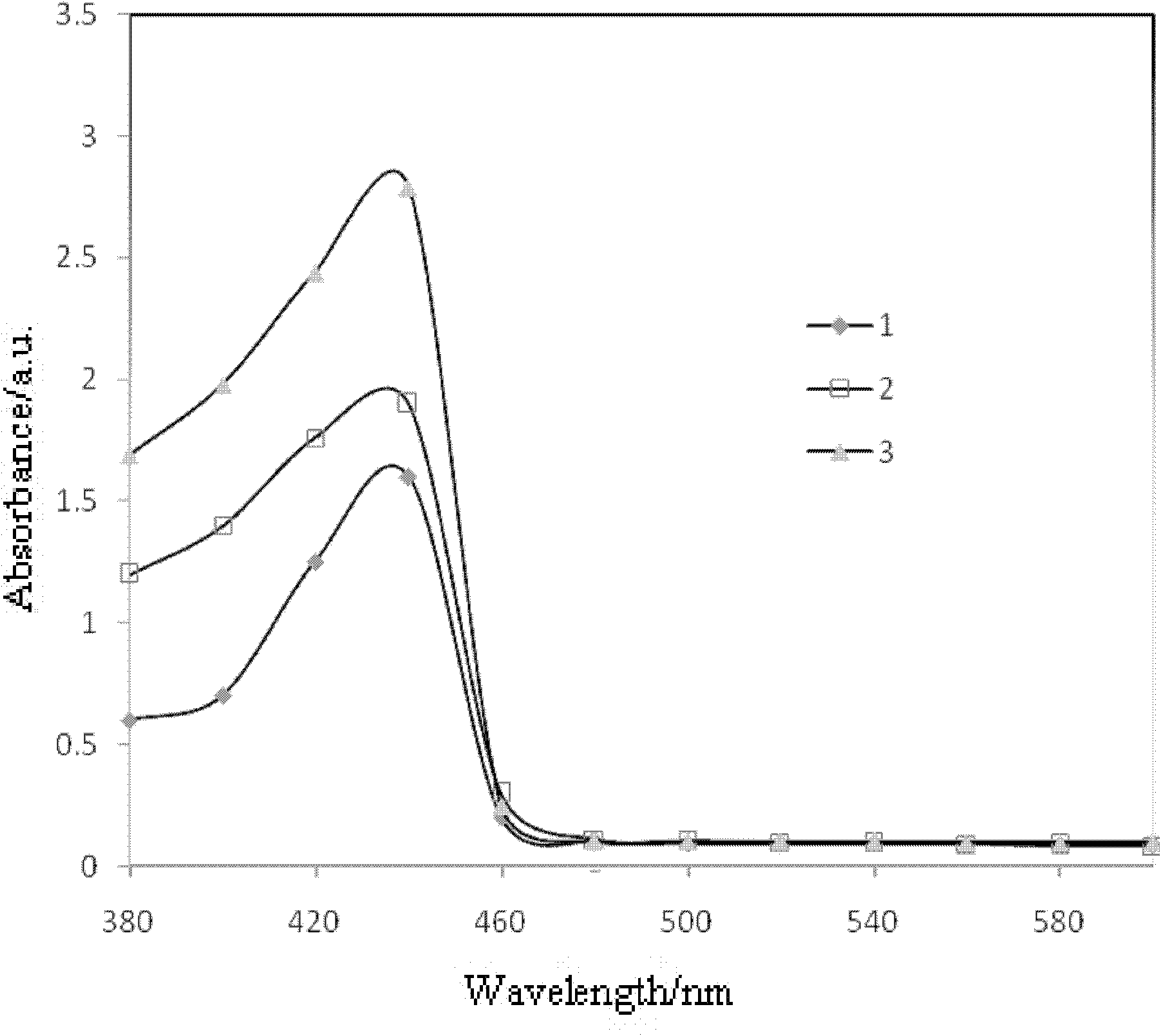

[0025] 1.1mmol / L 100mL cadmium nitrate solution, under the condition of constant stirring, add 100mL mercaptoacetic acid with a concentration of 1mmol / L dropwise. After the addition, adjust the pH to 11 with NaOH solution. After the pH value of the solution is stable, pass nitrogen to remove oxygen. , and then add 1.2mmol / L 100mL sodium sulfide solution dropwise, heat and control the temperature at 90°C, continue to stir thoroughly for 30min, and immediately carry out solid-liquid separation after the reaction, to obtain surface-modified functional cadmium sulfide ultrafine particles CdS / -SCH 2 COOH, its UV-Vis absorption spectrum analysis such as figure 1 Shown in line 1.

Embodiment example 2

[0027] 1.1mmol / L 100mL cadmium nitrate solution, under the condition of constant stirring, add 100mL mercaptoacetic acid with a concentration of 2mmol / L dropwise. After the addition, adjust the pH to 11 with NaOH solution. After the pH value of the solution is stable, pass nitrogen to remove oxygen. Finally, add 1.2mmol / L 100mL sodium sulfide solution dropwise, then heat and control the temperature at 90°C, continue to stir thoroughly for 30min, and immediately carry out solid-liquid separation to obtain CdS / -SCH 2 COOH sample, its UV-Vis absorption spectrum analysis such as figure 1 Shown in line 2.

Embodiment example 3

[0029] 1mmol / L 100mL cadmium nitrate solution was added dropwise to 100mL thioglycolic acid with a concentration of 3mmol / L under constant stirring. After the addition was completed, the pH was adjusted to 11 with NaOH solution. Then add 1.2mmol / L 100mL sodium sulfide solution dropwise, heat and control the temperature at 90°C, continue stirring for 30min, and immediately carry out solid-liquid separation to obtain the final CdS / -SCH 2 COOH sample, its UV-Vis absorption spectrum analysis such as figure 1 Shown in line 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com