Grouting guide pipe restraint ring mounting structure and method for mounting grouting guide pipes by using restraint rings

A technology of grouting conduits and confinement rings, which is applied in basic structure engineering, buildings, sheet pile walls, etc., can solve problems such as troublesome handling, increased construction costs, and hidden dangers in project quality, and achieves simple and easy-to-operate construction methods, saving construction and Construction cost, effect of guaranteeing construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

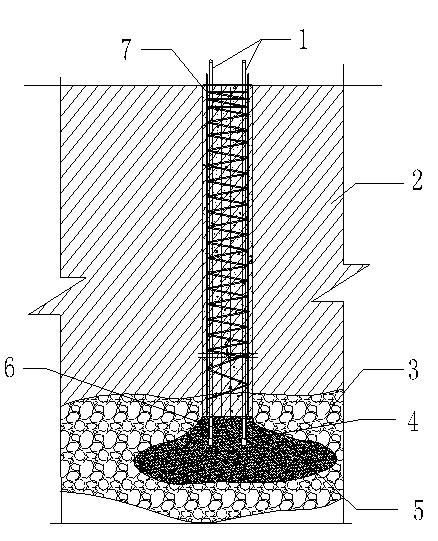

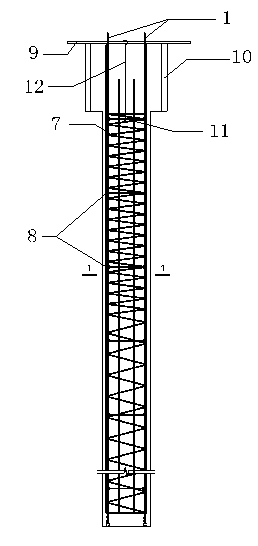

[0029] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0030] The construction steps of the method for installing the grouting conduit using the restraint ring in the present invention are as follows:

[0031] First, the constraining ring is made; then the constraining ring is fixed in sequence; the grouting conduit is installed; the cage is inserted into the hole and loosened in place.

[0032] Specific steps:

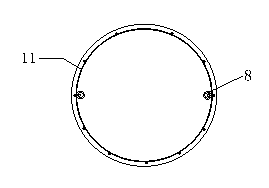

[0033] a. make the restraint ring 8 of restraint grouting conduit 1;

[0034] b. fix the restraint ring 8; the restraint ring 8 welded and fixed on the inner side of the reinforcing rib 11 on the steel cage 7 that has been bound;

[0035] c. Install the grouting conduit 1; insert the grouting conduit into the confinement ring 8 one by one along the length of the reinforcement cage, and use 12# iron wire 13 to temporarily bind the grouting conduit and the reinforcement cage at the position of each confineme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com